Preparation method of zirconium acetate solution with low free acetic acid

A zirconium acetate, low-free technology, applied in carboxylate preparation, organic chemistry, etc., can solve the problems of unrecovered acetic acid, large amount of acetic acid used, and strong odor of acetic acid, so as to shorten the production cycle, save consumption, and reduce the environment the effect of the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

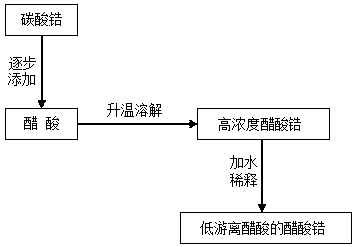

[0022] A kind of zirconium acetate solution preparation method of low free acetic acid, see figure 1 , the steps are as follows:

[0023] 1) Preferentially choose zirconium carbonate with good activity, that is: one part of zirconium carbonate consumes less than 0.6 parts of acetic acid;

[0024] 2) Put acetic acid into the electric heating enamel reaction kettle, and the amount of acetic acid put in is 20% to 60% of the volume of the container;

[0025] 3) According to the weight ratio of zirconium carbonate and acetic acid in the enamel reaction kettle in step 2) of 1:0.35~0.6, gradually add zirconium carbonate, stir, heat up and dissolve, control the temperature range from 20 ℃ to 80 ℃, and react until the solution is clear ( That is: 0.1 g of zirconium carbonate is put into the solution and dissolved until it becomes clear for more than 30 minutes), and a high-concentration zirconium acetate solution is obtained, and the content of zirconia in this solution is 28% to 31%;...

Embodiment 1

[0034] A kind of zirconium acetate solution preparation method of low free acetic acid is as follows (as figure 1 shown):

[0035] 1) Preferentially select one part of zirconium carbonate to consume less than 0.6 parts of active zirconium carbonate by weight of acetic acid;

[0036] 2) Put acetic acid into the electric heating enamel reaction kettle, and the amount of acetic acid put in is 30% of the volume of the container;

[0037] 3) Add zirconium carbonate gradually to the enamel reaction kettle in step 2) according to the weight ratio of zirconium carbonate to acetic acid of 1:0.4, stir, heat up and dissolve, control the temperature range to 50 °C ± 5 °C, and react until the solution is clear (ie: 0.1 g of zirconium carbonate is put into the solution and dissolved until it becomes clear for more than 30 minutes), and a high-concentration zirconium acetate solution is obtained, and the content of zirconium oxide in this solution is 30%;

[0038] 4) Dilute the high-concen...

Embodiment 2

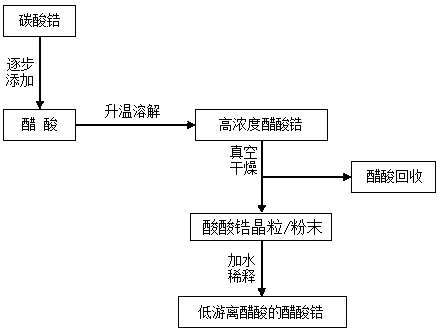

[0040] The zirconium acetate solution preparation method of another kind of low free acetic acid is as follows (as figure 2 shown):

[0041] 1) to 3) steps are the same as steps 1) to 3) in Example 1;

[0042] 4) Using double-cone vacuum drying equipment, vacuum-dry the high-concentration zirconium acetate solution in step 3) to obtain zirconium acetate grains / powder, the zirconium oxide content in the zirconium acetate grains / powder is 48%, and recover acetic acid;

[0043] 5) Use step 4) to dilute the zirconium acetate grains / powder with water to prepare a zirconium acetate solution with 5% zirconia content and low free acetic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com