High-frequency shifting fork quenching device

A quenching device and high-frequency quenching technology, which are applied in the direction of quenching devices, energy efficiency, process efficiency, etc., can solve the problems of difficult control of metal workpieces, low yield rate of metal quenching treatment, difficult quenching processing at the quenching position, etc. To achieve the effect of easy access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

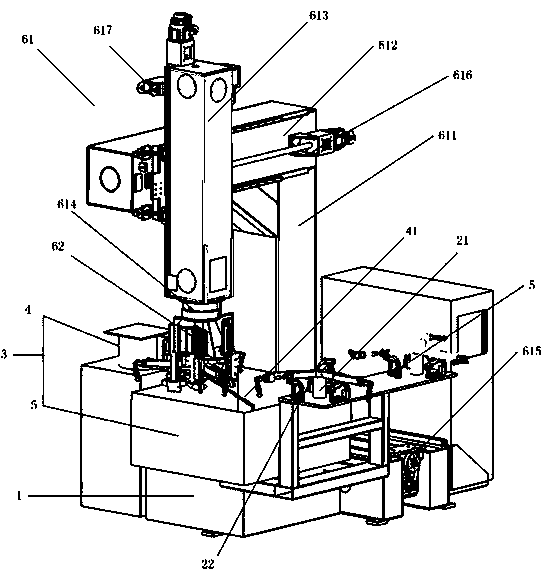

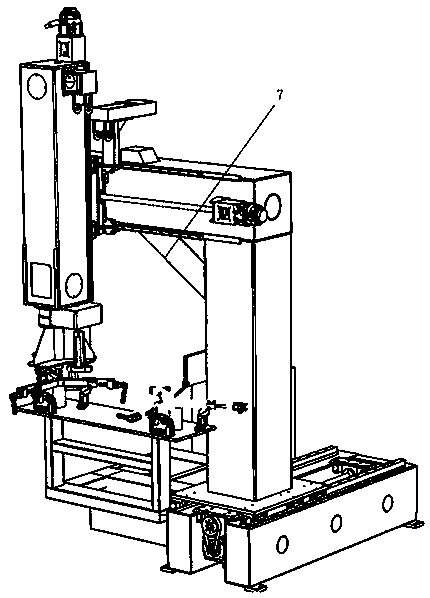

[0033] Such as Figure 1-5 The present invention discloses a high-frequency fork quenching device, the high-frequency fork quenching device includes a base 1, a high-frequency quenching device 4 and control equipment,

[0034] The base 1 is provided with a fork placement table 2 and a high-frequency quenching work area 3;

[0035] The high-frequency quenching working area 3 is provided with a high-frequency quenching device 4 and a pool 5, the high-frequency quenching device 4 is provided with a quenching rod 41, and the end of the quenching rod 41 extends into the pool 5;

[0036] The shift fork placement table 2 is provided with a plurality of placement slots 21, the placement slots 21 are placed with a shift fork carrier 22, and the shift fork carrier 22 is equipped with at least two shift forks. The shift fork carrier 22 moves to the high frequency quenching work area 3 through the shift fork moving device;

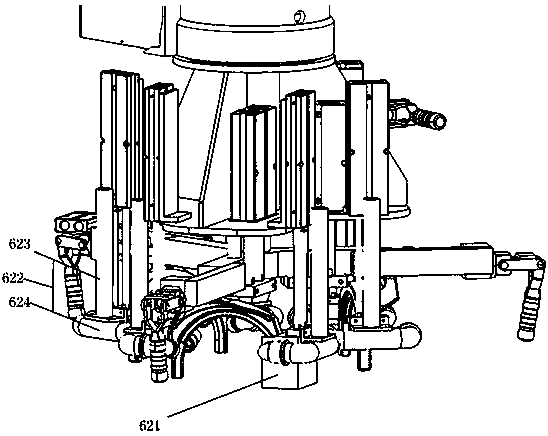

[0037] The shift fork moving device includes a four-axis linka...

Embodiment 2

[0045] The specific operation of the clamping and placement of the shift fork is to put the top end of the OEM shift fork into the front pin of the load arm, operate the piston rod in the short arm of the locking frame body, move the piston rod to offset the shift fork, and press the lock body Press down to tighten the position of the piston rod, and then adjust the adjustable screw to further clamp the processing fork, so that the fork is tightly assembled on the fork carrier. After the fork carrier is fully loaded with the fork, put the Put the fixed column on the shift fork carrier into the placement slot, abut one section of the shift fork against the horizontal positioning block to realize the lateral positioning of the shift fork, and then fit the other end of the shift fork to the angle image of the longitudinal positioning block to complete the shifting fork Longitudinal positioning to realize the clamping placement of the shift fork.

Embodiment 3

[0047] During the specific operation, the X moving axis in the shift fork moving device slides through the X-axis motion guide rail, moves the feeding manipulator to be level with the placement table, and then starts the Y moving axis to make the Z moving axis slide on the Y-axis motion guide rail. The feeding manipulator moves to the top of the shift fork carrier to be clamped, starts the Z moving axis, makes the Z moving axis move relative to the Y moving axis through the Z-axis motion guide rail, moves up and down along the Z-axis direction, and lowers the feeding manipulator to the carrier frame Level, start the fixed block of the carrier frame, the cylinder pushes the fixed block of the carrier frame down until the fixed block of the carrier frame is lower than the fork carrier frame, start the rotary feeding manipulator of the A rotation axis, rotate the fixed block of the carrier frame to the right below the carrier frame, and the cylinder Drive the fixed block of the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com