Clamping device based on tubular IPMC drive

A clamping device and tubular technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of large external interference, large volume and high cost, and achieve the effects of good application prospects, small overall volume and simple structure

Pending Publication Date: 2022-07-15

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, tubular IPMC has been proposed to be used in the field of interventional therapy, but due to its single function, it can only be used for bending guidance, but cannot achieve clamping and obstacle-clearing movement; in microfinishing and aerospace, the application of traditional IPMC is mainly It is sheet-shaped bending deformation to realize clamping movement, and its guiding function is mostly completed by mechanical devices, with complex structure and high cost

[0004] The driving mode of the traditional clamping device is external drive, and the structure is complex and the volume is large, which cannot meet the application in the high-precision field of micro space, and is greatly affected by external interference; in the field of interventional therapy, the traditional clamping method is still through the mechanical structure, and there is no Guidance function, dependent on interventional catheter, difficult to operate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

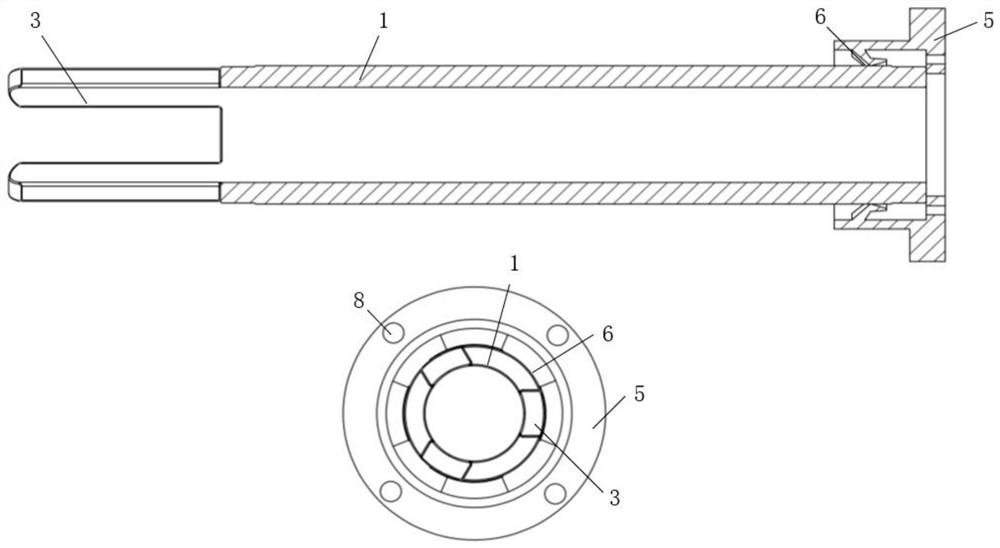

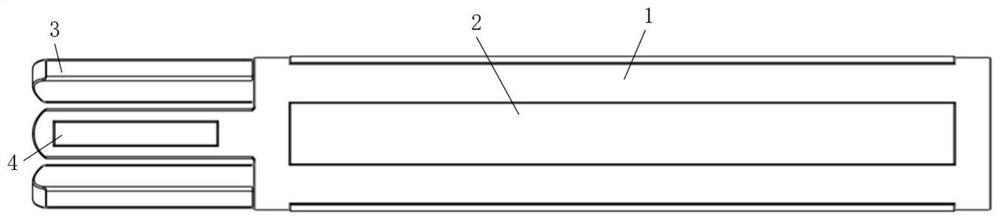

[0052] As a specific embodiment of the present invention, the No. 1 electrode 2 and the No. 2 electrode 4 do not overlap.

[0053]In the present invention, by setting the No. 1 electrode 2 and the No. 2 electrode 4 to have no overlap, signal interference is prevented, resulting in disorder of the signals of the No. 1 electrode 2 and the No. 2 motor, resulting in the situation that the present invention cannot work normally.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

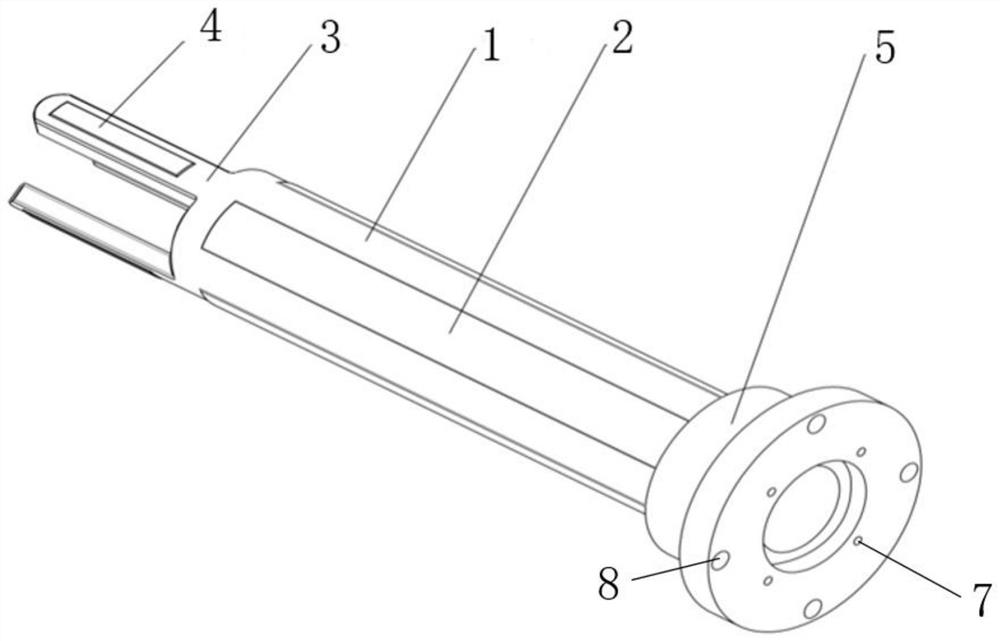

The invention relates to a clamping device based on tubular IPMC drive, the clamping device based on tubular IPMC drive comprises a tube body, the outer surface of the tube body is provided with a first electrode, the tube body is made of IPMC materials, and bending guide motion of the tube body is controlled by changing an electric signal of the first electrode; the clamping jaw is arranged at the front end of the tube body, a second electrode is attached to the surface, coinciding with the outer surface of the tube body, of the clamping jaw, and control over clamping and releasing of the clamping jaw is achieved by controlling an electric signal of the second electrode; the base is connected with the tail end of the tube body, and an elastic metal sheet is embedded in the inner surface of the base. According to the clamping device based on tubular IPMC driving, integrated design is adopted, the overall size is small, the weight is low, the manufacturing cost is saved, the requirements for narrow space work, micro-precision instrument assembly and the like can be met, and the clamping device has good application prospects in the fields of aerospace, minimally invasive medical treatment and the like.

Description

technical field [0001] The invention relates to the composite application field of intelligent materials, in particular to a clampable device driven by a tubular IPMC. Background technique [0002] With the development of science and technology, clamping devices are widely used in industrial production lines, micro-finishing fields, aerospace fields, etc., but most of the devices are made of rigid materials, which are not only large in size, but also in overall weight, making it difficult to To meet the use of some special spaces. At the same time, this kind of device is mostly driven by motor, hydraulic drive, or manual operation, which is greatly affected by external disturbances such as magnetic field, temperature and external force, and it is difficult to complete work tasks in many special fields. [0003] IPMC is an ionic EAP electro-actuated polymer. The actuating mechanism of the material is that under the action of an electrical signal, water and cations in the bas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25B11/00

CPCB25B11/00

Inventor 吕志豪刘复乐何青松兰豪郭雯诣肖景元

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com