A road bridge structure for protecting shallow buried pipelines in building municipal road engineering and its application method

A municipal road and engineering technology, applied in the directions of roads, buildings, roads, etc., can solve the problems of unadjustable area, easy damage of pipelines and lines, and large single-piece mass and area of large steel plates, so as to achieve convenient coverage area, The effect of increasing the coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

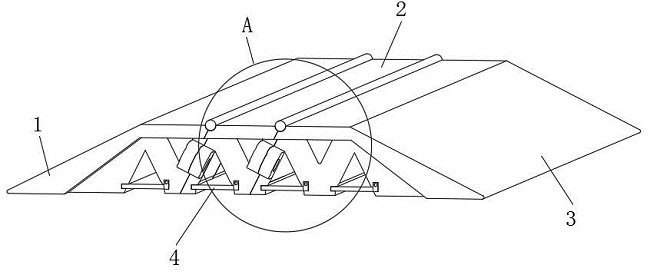

[0046] refer to Figure 1-4 , a road bridge structure for protecting shallow buried pipelines in municipal road engineering, including a first approach bridge 1, a docking bridge 2 and a second approach bridge 3,

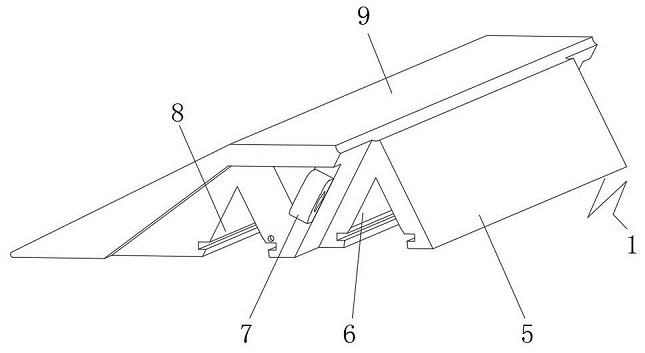

[0047] The first approach bridge 1 includes a first butt joint tongue 5, a first wire hole 6 and a first bridge frame 9, the first butt joint tongue 5 is fixedly connected to the front end of the first bridge frame 9, and the first wire pass hole 6 is opened on the first butt joint tongue the lower end of 5;

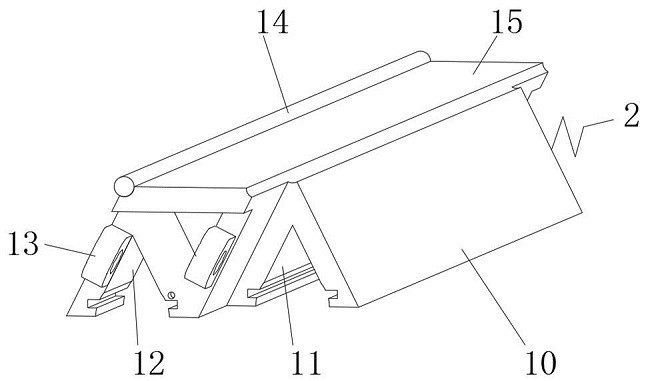

[0048] The docking bridge 2 includes a second docking tongue 10, a third wire passing hole 11, a fourth wire passing hole 12 and a second bridge frame 15, the second docking tongue 10 is fixedly connected to the front end of the second bridge frame 15, and the third wire passing hole 11 Opened at the lower end of the second butt joint tongue 10, the fourth wire passing hole 12 is opened at the lower end of the second bridge frame 15, and the first butt joint ...

Embodiment 2

[0066] refer to Figure 2-4 , a road and bridge structure used to protect shallow buried pipelines in construction municipal road projects, which is basically the same as embodiment 1, and furthermore, the first wire hole 6, the second wire hole 8 and the third wire hole 11 , the fourth wire hole 12, the fifth wire hole 16 and the sixth wire hole 17 inner walls are provided with chute, through the chute to facilitate the insertion of the partition 4 work.

[0067] The side end of the partition plate 4 is screwed to the first approach bridge 1, the docking bridge 2 and the second approach bridge 3, and is fixed to the first bridge frame 9, the second bridge frame 15 and the third bridge frame 18 through the side end of the partition plate 4 by means of external screws , with the help of external screws, the partition plate 4 is fixed to the first approach bridge 1, the docking bridge 2 and the second approach bridge 3, which prevents the partition plate 4 from slipping out afte...

Embodiment 3

[0069] refer to Figure 5 , a road bridge structure used to protect shallow buried pipelines in construction municipal road engineering, basically the same as embodiment 1, the side ends of the first approach bridge 1, the docking bridge 2 and the second approach bridge 3 are slidably inserted with clamping blocks 21 and a block 23, the side ends of the block 21 and the block 23 are fixedly connected with a support 22, the support 22 is screwed with the docking bridge 2 or the second approach bridge 3 through screws, and the block 21, the block 23 And the bracket 22 is directly fixed by the side of the device, which reduces the difficulty of reinforcement.

[0070] Working principle: When assembling, insert the first butt tongue 5 into the rear of the second bridge frame 15, so that the first wire-passing hole 6 and the fourth wire-passing hole 12 form a complete slot, and cover the formed slot on the target pipeline , if the line is placed directly on the ground surface, lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com