Pin fastening component

A technology for fastening components and pins, applied in the field of pin fastening components and formwork, can solve the problems that the pins are not easily inserted into the holes of the pins, affect the pouring quality of the concrete wall, and the pins and pin connections are easy to loosen, etc. The effect of convenient and quick disassembly, simple structure, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

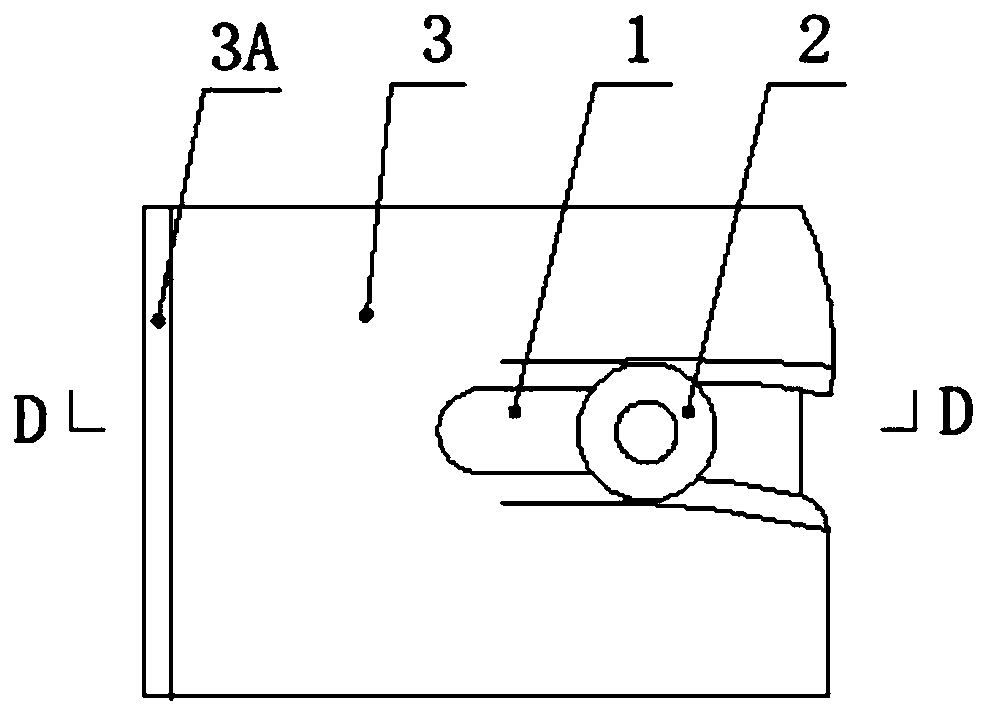

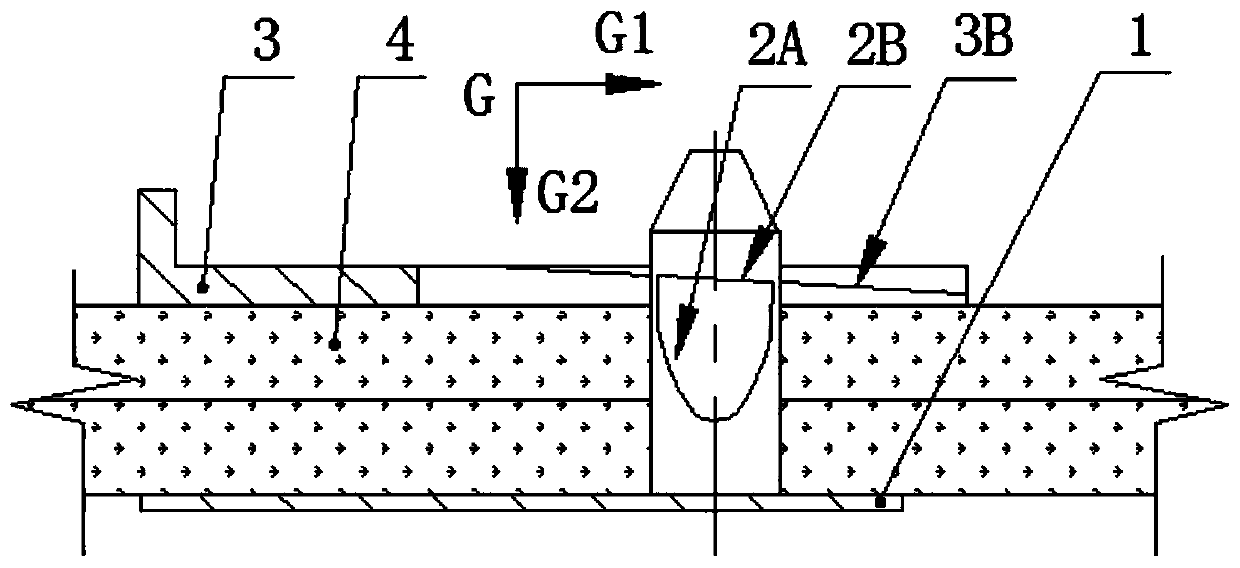

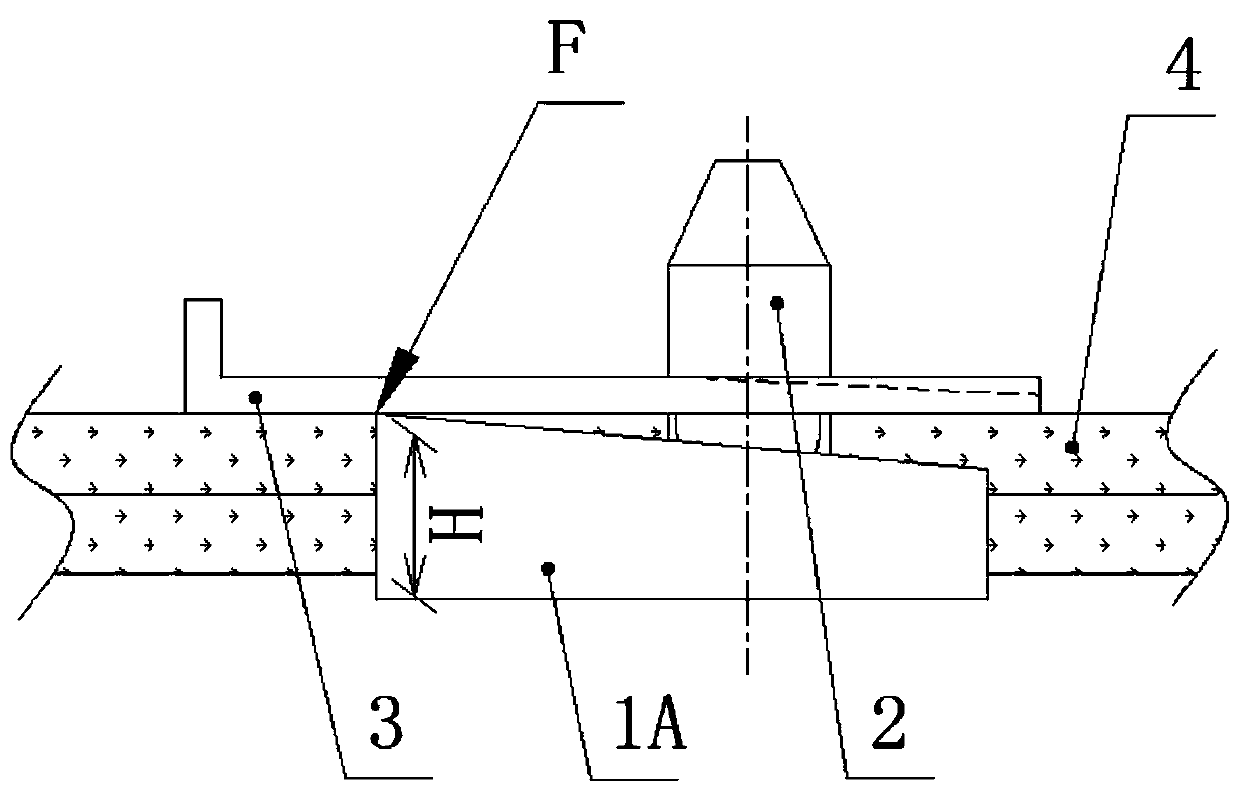

[0046] A pin fastening member such as Figure 1 to Figure 3 As shown, it includes a pin 2 and a pin piece 3, the inner end of the pin is fixed on the splint 1, and one side of the pin piece is formed with a draw-in groove 3A for accommodating the pin, as Figure 4 shown.

[0047] The specific structure of the pin is as follows:

[0048] 2. The outer edge of the pin is symmetrically formed with a first clamping slope 2A along the axial direction, such as image 3 As shown, the inclination angle β between the first clamping slope and the axis of the pin is 10-25 degrees, the first clamping slope corresponds to the second clamping slope 2B formed on the outer edge of the pin, and the second clamping The inclination angle α of the slope is 3-10 degrees. In order to facilitate the pins to be inserted into the formwork holes and the slots of the pins during installation, the pins have a truncated cone structure or the outer end of the pins has a truncated cone structure.

[0049...

no. 2 example

[0057] On the basis of the above-mentioned first embodiment, two parts of the screw rod 6 and the threaded sleeve 5 are added, specifically as Figure 6 , Figure 7 As shown, a screw rod is fixedly installed on the pin sheet corresponding to the side of the pin sheet slot, and the screw rod is threadedly connected in the threaded sleeve fixed on the splint. The card slot is an arc structure.

[0058] The tail portion of the pin piece is an arc structure, which is exquisite in structure, easy to use, strong in practicability, and durable in purpose.

[0059] Through the setting of the screw and the threaded sleeve, it not only has the advantages of the pin piece rotating around the screw rod, increasing the positioning point, and preventing the screw from falling out, but more importantly, the process of the pin piece and the pin being matched through the thread cooperation between the screw rod and the threaded sleeve The purpose of clamping gradually, and finally clamping the...

no. 3 example

[0062] Such as Figure 8 As shown, on the basis of the second embodiment, the splint is lengthened, and a group of pins and pin pieces are added. Two groups of pins and pin sheets are installed on the splint, and the two groups of pins and pin sheets are arranged at intervals up and down.

[0063] Through the design of conjoined pins and pins, its acceptance is larger and stronger, and it is suitable for independent columns, stairs, wall formwork, and any position where there is no way to set pull tabs and back corrugations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com