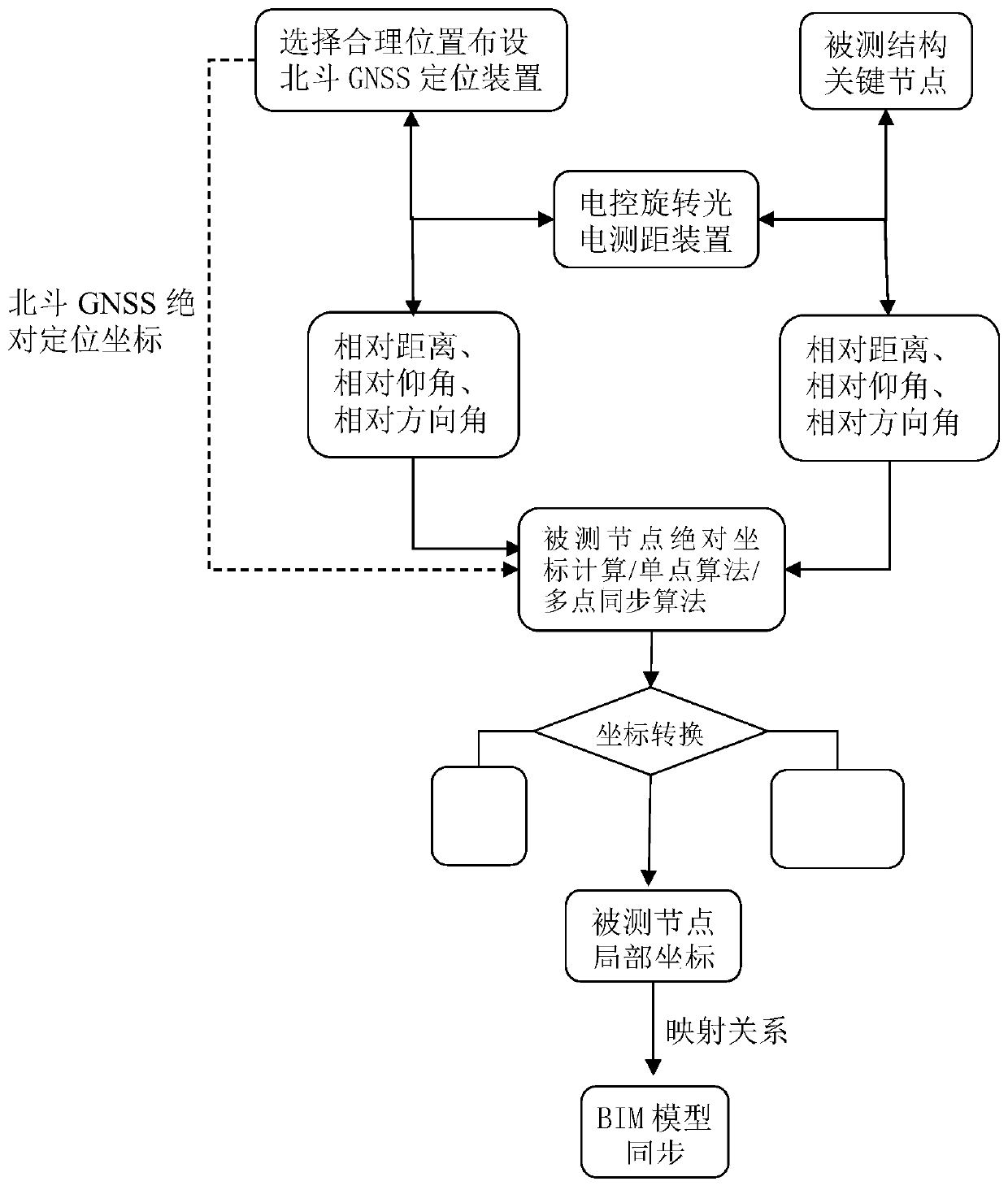

Structure construction multi-point synchronous high-precision positioning method based on Beidou GNSS & BIM

A positioning method and high-precision technology, applied in satellite radio beacon positioning system, building structure, building material processing, etc., can solve the problems that cannot meet the large-scale monitoring of large-span structure construction, to ensure accuracy and synchronization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1, an international convention and exhibition center project in a coastal city along the river, including two main bodies, the conference center and the exhibition center, with a total construction area of about 123,000 m 2 . The structural roof adopts steel truss and steel grid roof respectively, and correspondingly adopts jacking and sliding construction. In order to control the deflection deformation of the steel roof joints during the jacking and sliding process, the method provided by the patent of the present invention is adopted, through 2 sets of high-precision GNSS positioning equipment and 2 sets of 360-degree high-precision electronically controlled photoelectric ranging devices Simultaneously monitor the lifting and sliding process of the steel structure to ensure a successful construction without safety and quality construction.

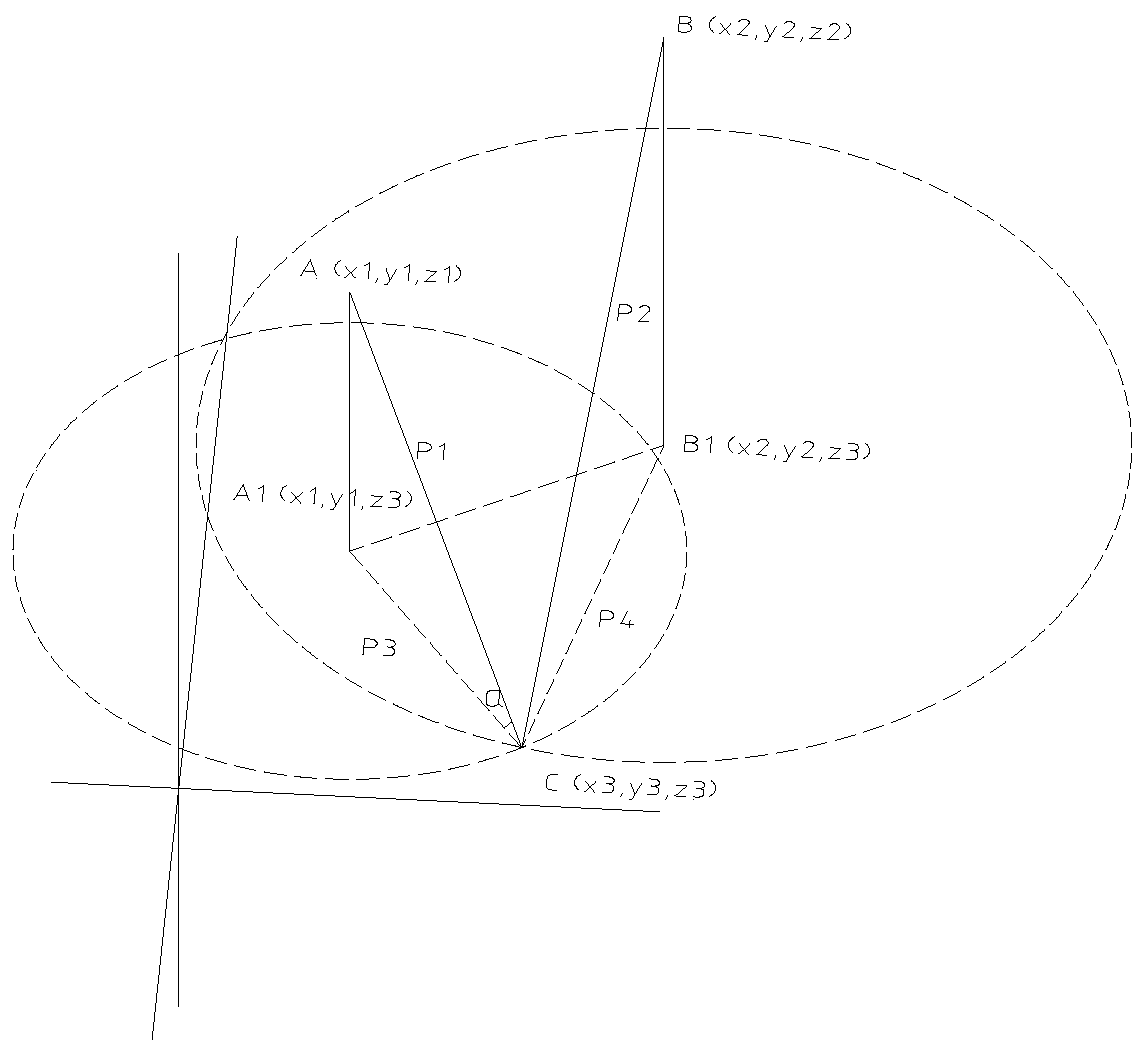

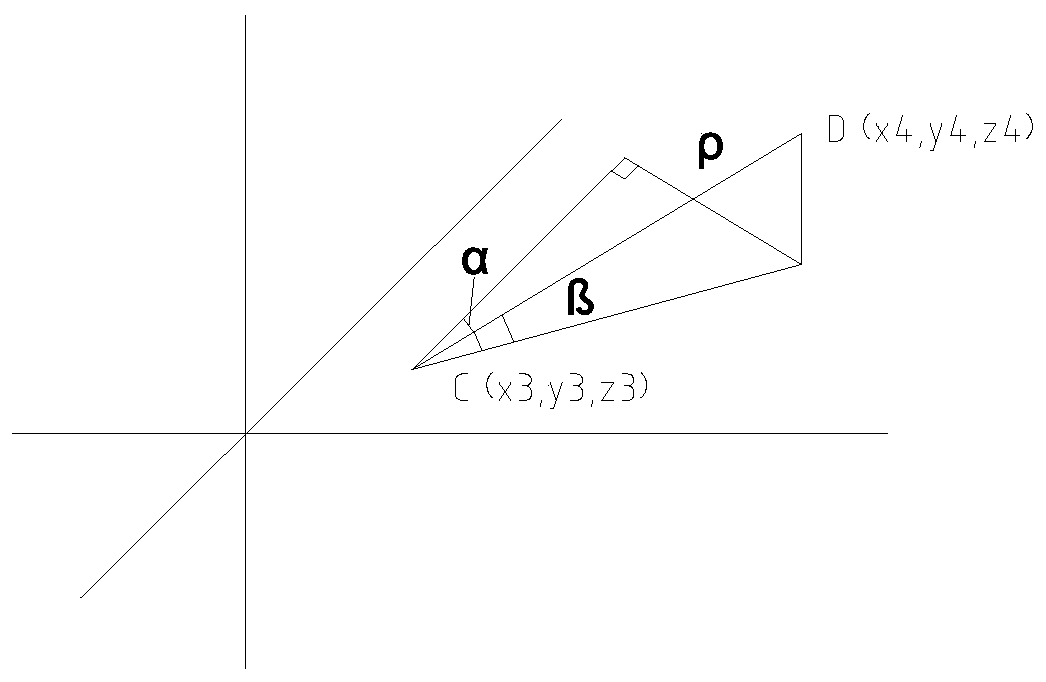

[0068] A multi-point synchronous high-precision positioning method for structural construction based on Beidou GNSS&B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com