Hinging device for heavy loads

A hinged, bearing surface technology, used in pivot connection, transportation and packaging, load hanging components, etc., can solve the problems of time-consuming and laborious installation, weakening the weight of related components, and heavy structure, so as to facilitate installation and save resource costs. , the effect of simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

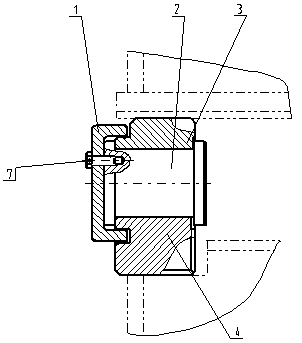

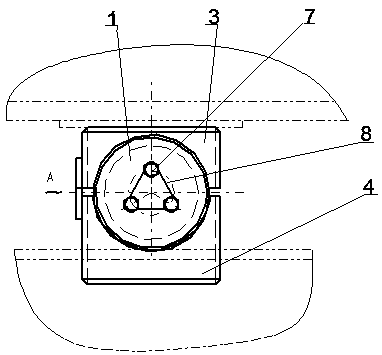

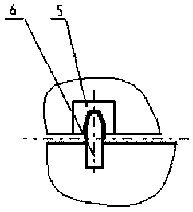

[0037] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 As shown, a hinged device for heavy load is composed of a pin shaft (2), an upper semicircular block (3), a lower semicircular block (4), a circular cover plate (1) and a rotation degree of freedom restriction system. The above-mentioned upper semicircular block (3) is placed above the pin shaft (2), the lower semicircular block (4) is placed under the pin shaft (2), and the inner side of the circular cover plate (1) is connected with the upper semicircular block (3) at the same time. ) and one end of the lower semicircle block (4).

[0038] The circular cover plate (1) and the pin shaft (2) are connected by 3 or 5 sets of screws (7), and the screws (7) are connected and reinforced by steel wires (8).

[0039] The screws (7) are located at 1 / 3 of the radius from the center of the circular cover (1) to the circumference, that is to say, 3 or 5 sets of screws (7) are located at the center of the circle w...

Embodiment 2

[0051] Such as figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 As shown, a hinged device for heavy load is composed of a pin shaft (2), an upper semicircular block (3), a lower semicircular block (4), a circular cover plate (1) and a rotation degree of freedom restriction system. The above-mentioned upper semicircular block (3) is placed above the pin shaft (2), the lower semicircular block (4) is placed under the pin shaft (2), and the inner side of the circular cover plate (1) is connected with the upper semicircular block (3) at the same time. ) and one end of the lower semicircle block (4).

[0052] The circular cover plate (1) and the pin shaft (2) are connected by 3 or 5 sets of screws (7), and the screws (7) are connected and reinforced by steel wires (8).

[0053] The screws (7) are located at 1 / 3 of the radius from the center of the circular cover (1) to the circumference, that is to say, 3 or 5 sets of screws (7) are located at the center of the circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com