Single-span beam vibration experiment system

An experimental system, single-span beam technology, applied in the field of single-span beam random vibration experimental system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

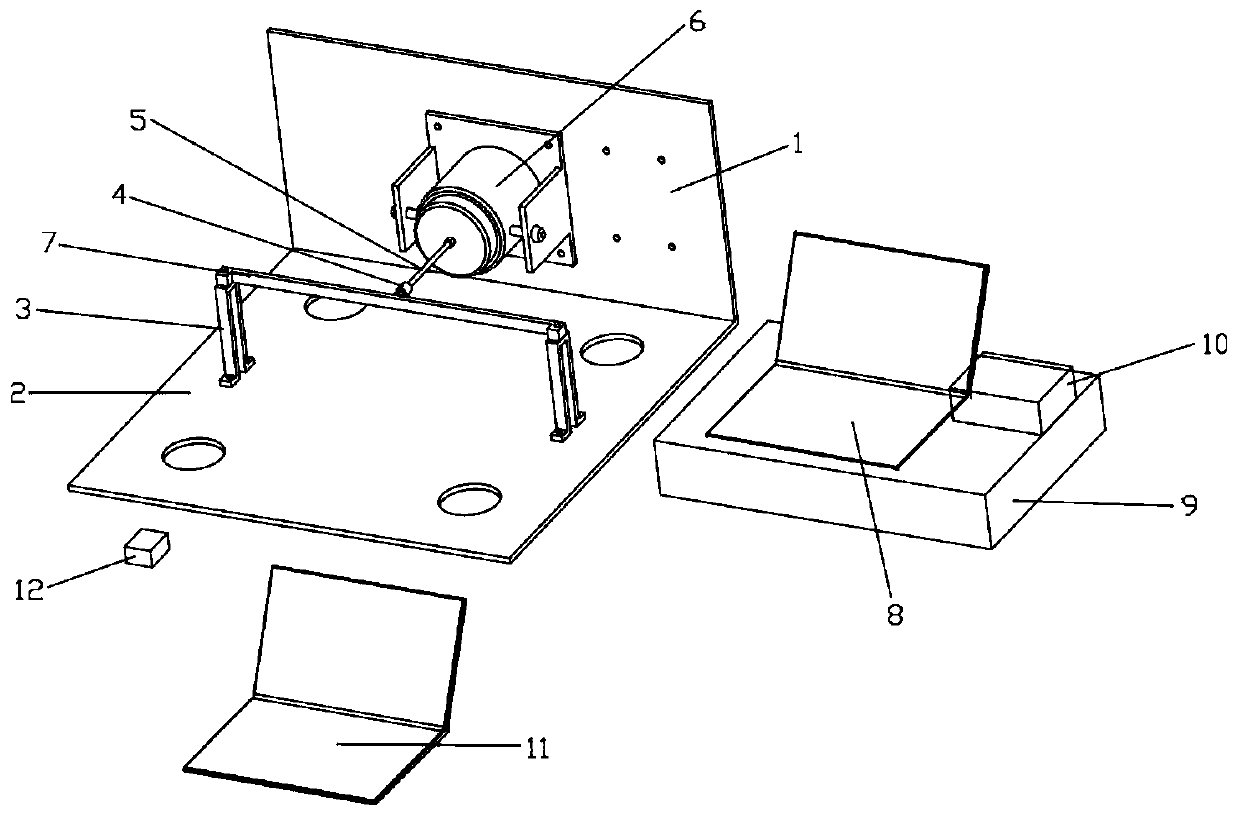

[0014] As shown in the accompanying drawings, the single-span beam vibration experiment system of the present invention includes a rectangular base, and a plurality of mounting holes are opened on the vertical plate 1 of the rectangular base, and the base of the exciter 6 passes through the The bolts in the mounting holes of the set positions are fixedly connected with the vertical plate 1 . The loading of different positions of the specimen beam can be realized by changing the position where the vibrator 6 is installed on the vertical plate 1 . The vibration exciter preferably adopts a powerful electrodynamic modal vibration exciter, which can provide excitation for the beam with a maximum excitation force of 100 N and a maximum amplitude of 10 mm.

[0015] On the left and right sides of the horizontal plate 2 of the rectangular base, a beam support 3 is respectively inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com