Unidirectional stress electromagnetic ultrasonic detection method

An electromagnetic ultrasonic, one-way stress technology, applied in the field of detection, to achieve the effect of high detection accuracy, high resolution and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

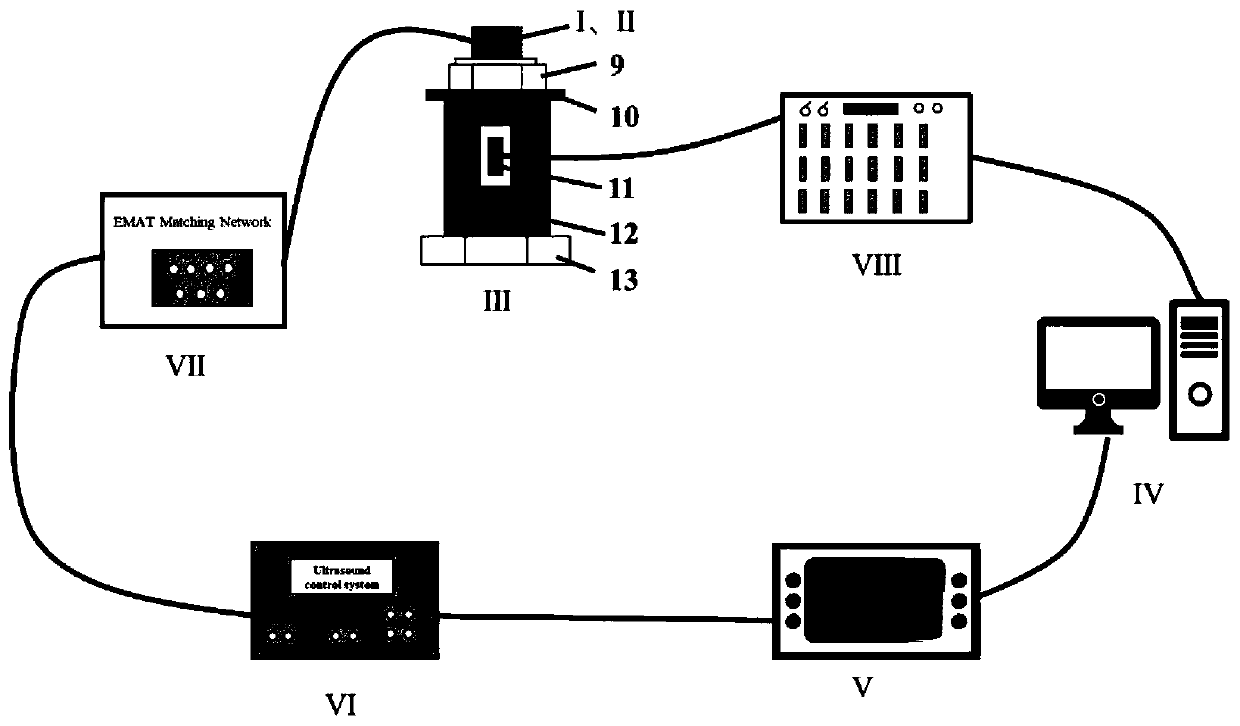

[0033] The method first assembles the electromagnetic ultrasonic detection system, and then respectively collects the signal waveforms of the unidirectional stress detection of the electromagnetic ultrasonic transverse wave probe Ⅰ and the electromagnetic ultrasonic longitudinal wave probe Ⅱ, and calculates the unidirectional stress through the theoretical formula of transverse and longitudinal wave joint detection. The specific steps of the method as follows:

[0034] The first step is to assemble the electromagnetic ultrasonic testing system

[0035] The electromagnetic ultrasonic testing system consists of electromagnetic ultrasonic transverse wave probe Ⅰ, electromagnetic ultrasonic longitudinal wave probe Ⅱ, unidirectional stress stretching platform Ⅲ, computer system Ⅳ, oscilloscope Ⅴ, ultrasonic control system Ⅵ, impedance matching network Ⅶ, and static strain testing device Ⅷ;

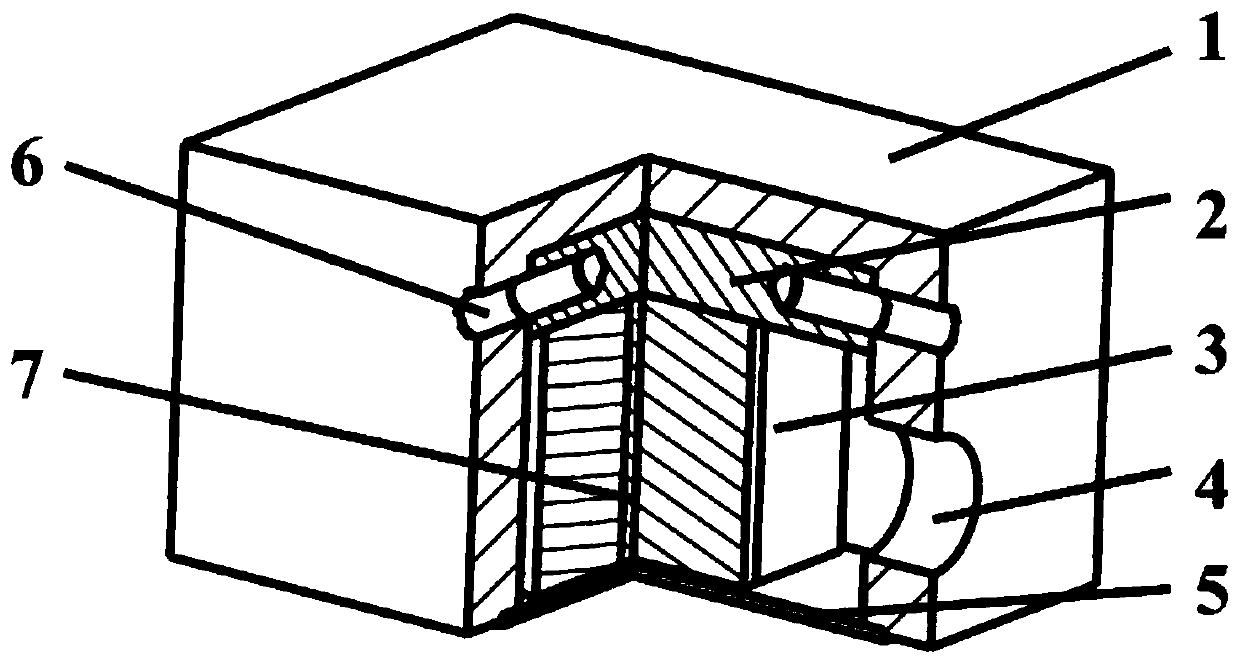

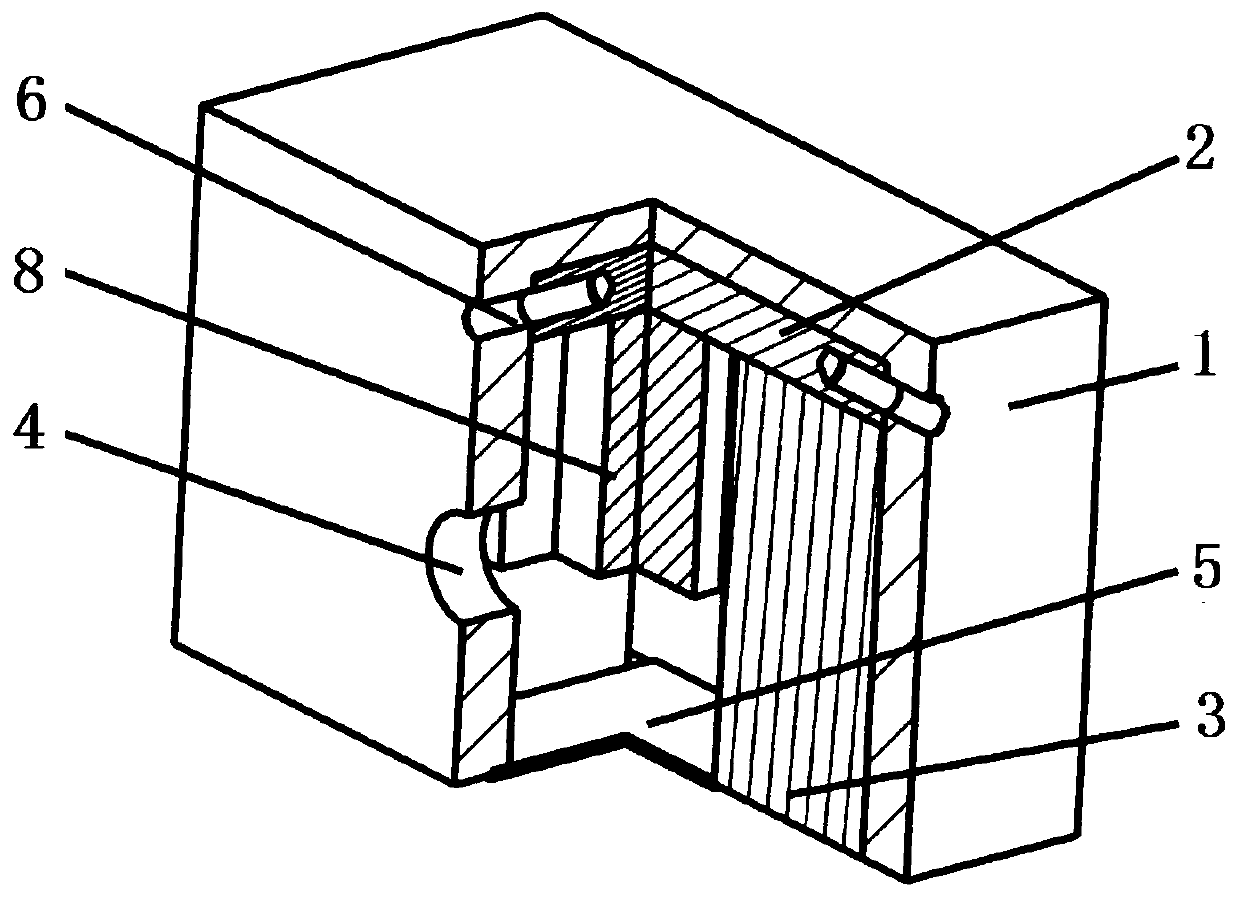

[0036] First assemble the electromagnetic ultrasonic transverse wave probe Ⅰ, attach the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com