Lithium deposition prediction method and device for a lithium-ion battery

A lithium-ion battery and lithium deposition technology, which is applied in measurement devices, measurement of electricity, measurement of electric variables, etc., can solve the problems of low prediction accuracy of lithium deposition, and achieve the effect of improving precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

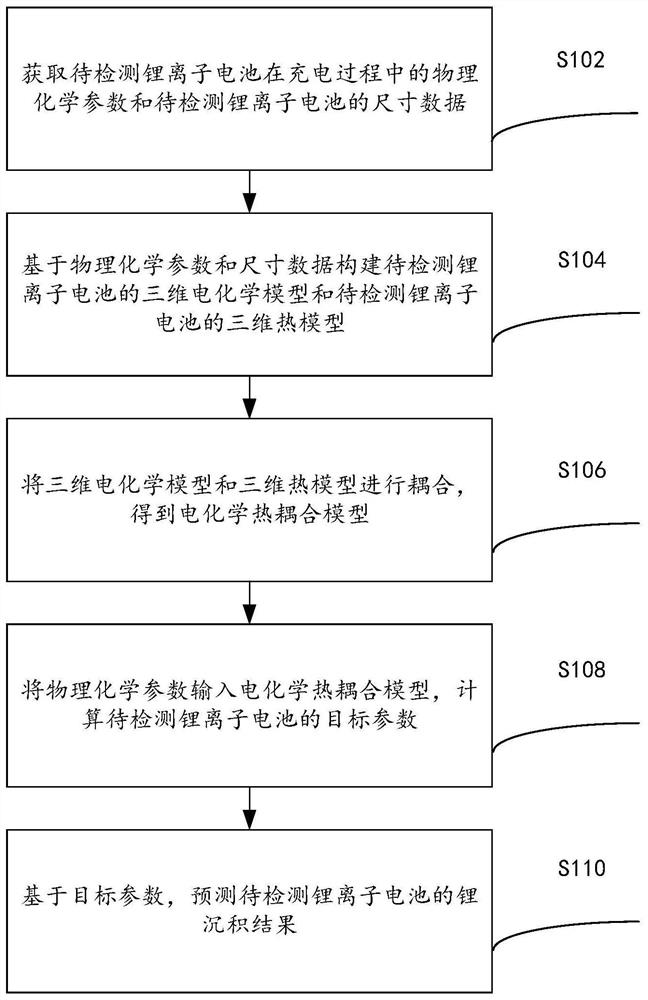

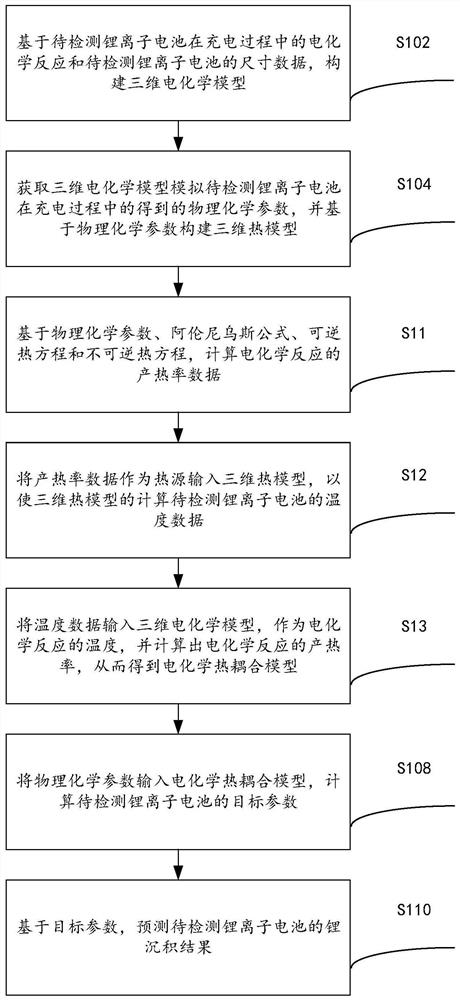

[0026] According to an embodiment of the present invention, a lithium deposition prediction method for a lithium-ion battery is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions, and , although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0027] figure 1 It is a flow chart of a lithium deposition prediction method for a lithium ion battery according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0028] Step S102, based on obtaining the physical and chemical parameters of the lithium-ion battery to be tested during the charging process and the size data of the lithium-ion battery to be tested;

[0029] Due to the difficulty of real-time and quantitative analysis...

Embodiment 2

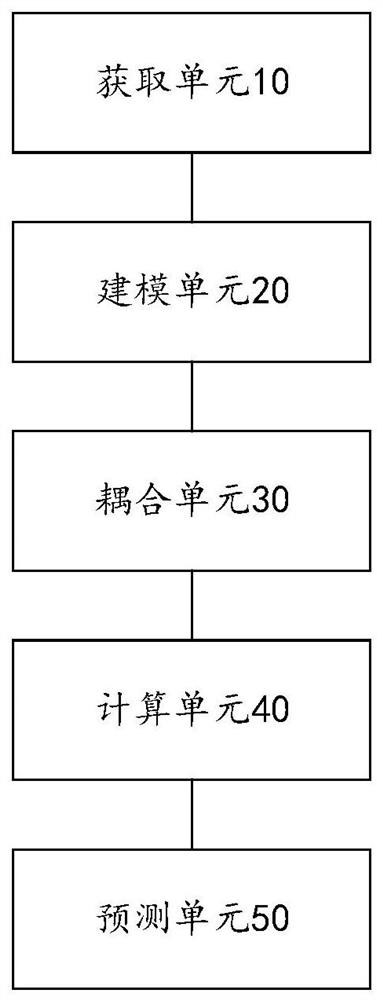

[0126] The present invention also provides a lithium-ion battery lithium deposition prediction device, which is used to implement the lithium-ion battery lithium deposition prediction method provided by the above-mentioned content of the embodiment of the present invention, the following is the lithium-ion battery provided by the embodiment of the present invention The specific introduction of the lithium deposition prediction device.

[0127] Such as image 3 Said, the device includes: an acquisition unit, a modeling unit, a coupling unit, a calculation unit and a prediction unit, wherein,

[0128] The acquisition unit 10 is used to acquire the physicochemical parameters of the lithium-ion battery to be tested during the charging process and the size data of the lithium-ion battery to be tested;

[0129] The modeling unit 20 is used to construct a three-dimensional electrochemical model of the lithium-ion battery to be tested and a three-dimensional thermal model of the lith...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com