Warehouse carrying robot

A technology for handling robots and robots, which is applied in the field of robots, can solve the problems that human operations are difficult to meet the needs of the market and efficient management, the temperature and humidity have special requirements, and personnel cannot stay for a long time, so as to avoid cargo handling errors, improve transportation efficiency, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

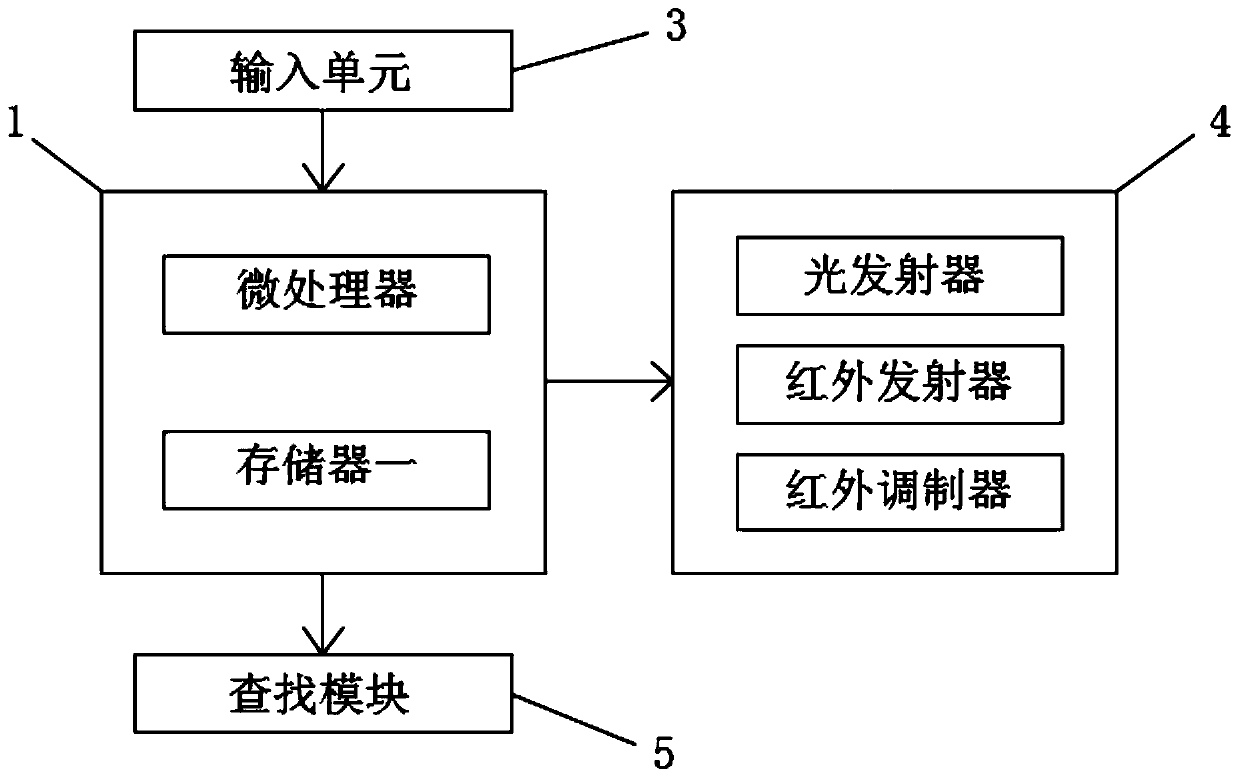

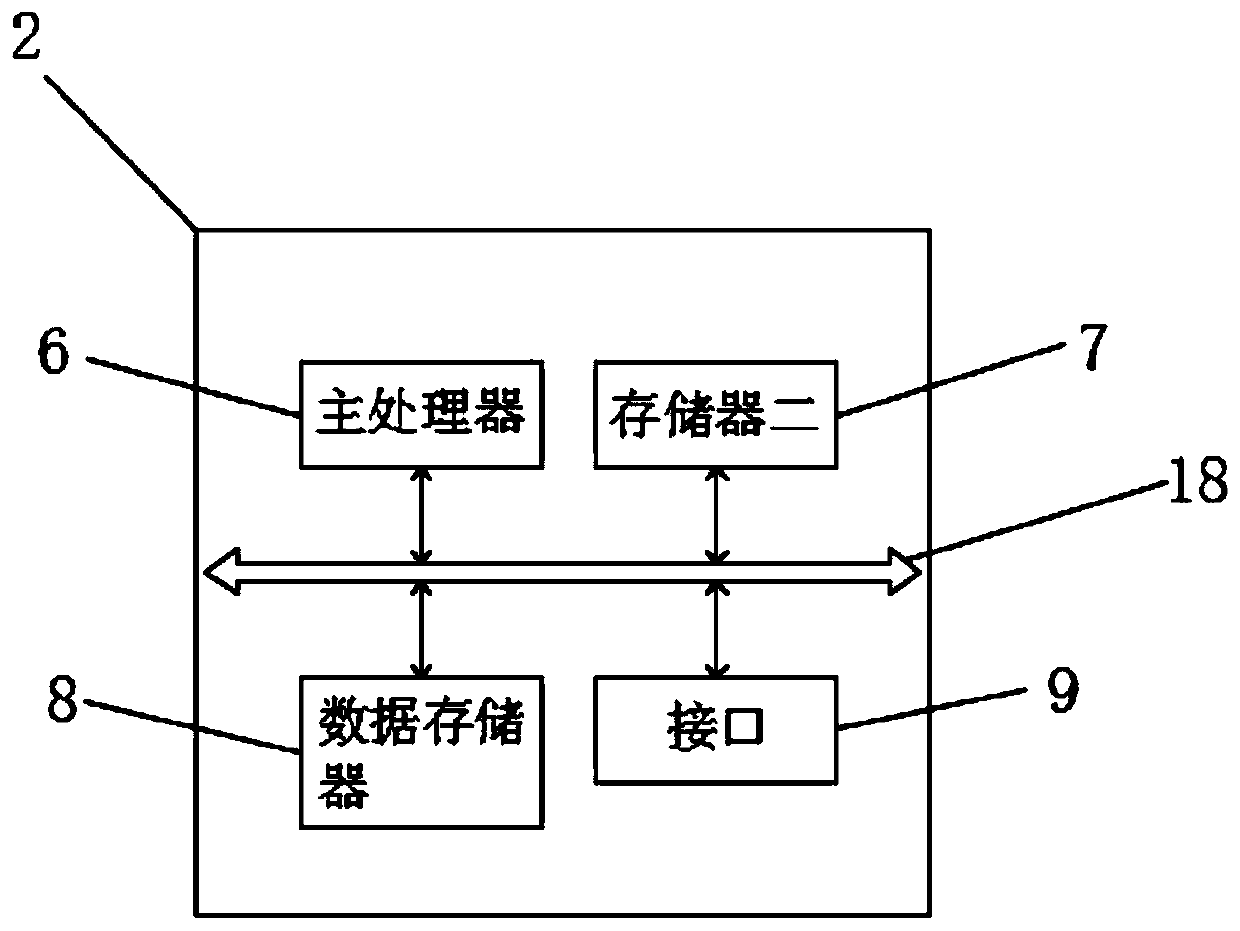

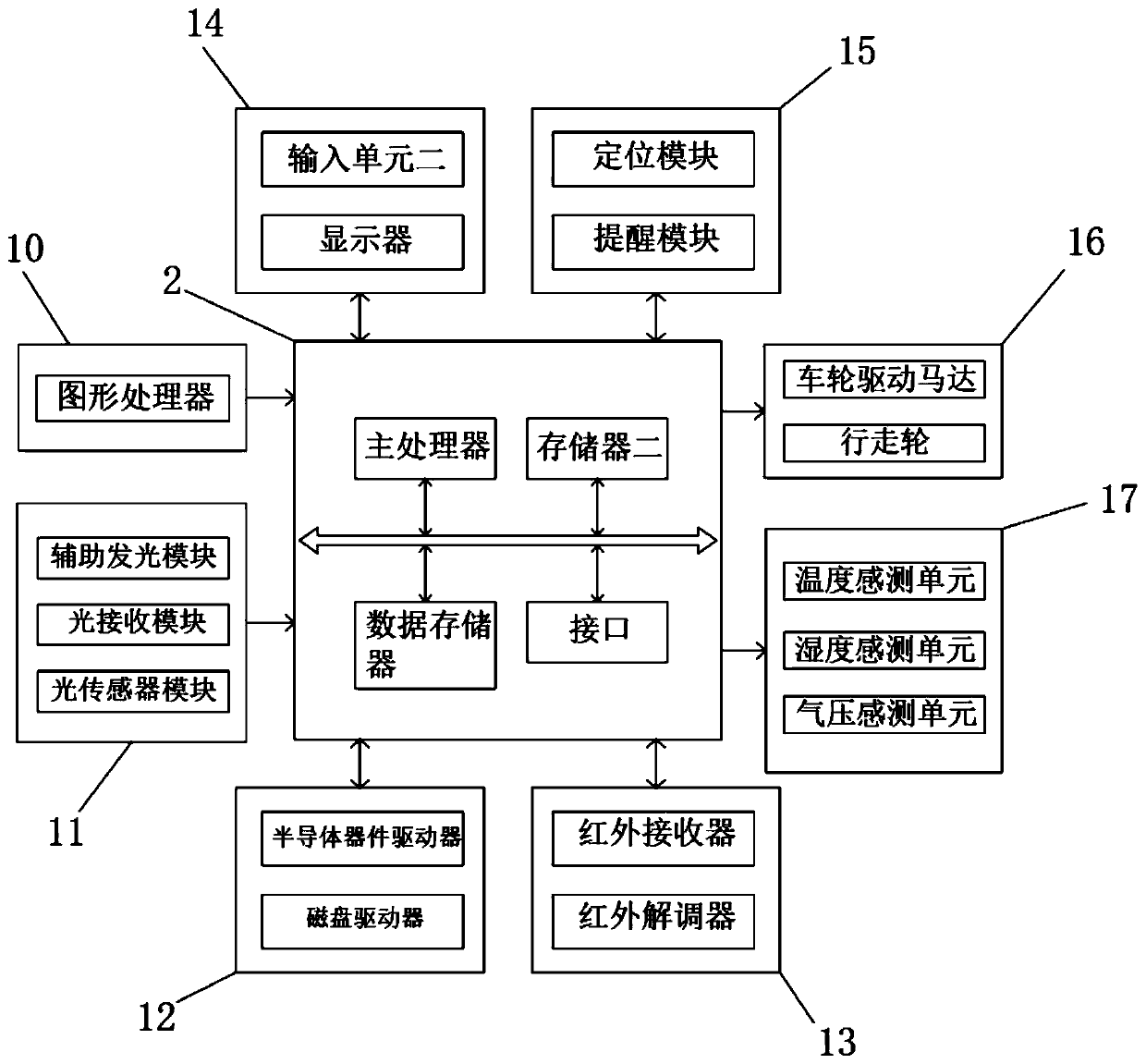

[0023] like Figure 1-3 As shown, a warehouse handling robot and its control method include a remote device control unit 1 and a robot control unit 2, the remote device control unit 1 includes a microprocessor 19 and a memory one 20, and the microprocessor 19 is located at one end of the memory one 20, Robot control unit 2 comprises main processor 6, memory two 7, data memory 8, interface 9 and system path bus 18, and main processor 6 and memory two 7 are all positioned at system path bus 18 side, and data memory 8 and interface 9 all Located on the other side of the system path bus 18, and the main processor 6 is located on the side of the memory 2 7, the data storage 8 is located on the side of the interface 9, the remote equipment control unit 1 is provided with an input unit 3, and the remote equipment control unit 1 side is provided with There is a light emitting unit 4, the remote device control unit 1 is internally connected with a search unit 5, one end of the robot co...

Embodiment 2

[0027] like Figure 1-3 As shown, the light-emitting unit 4 includes a light emitter, an infrared emitter and an infrared modulator, and the search unit 5 includes a search module; the light emitter is used to emit visible light, the infrared emitter is used to emit infrared rays, and the infrared modulator is used for modulation of infrared rays; the search module For finding the location of the warehouse handling robot, the image acquisition unit 10 includes a graphics processor, and the obstacle detection unit 11 includes an auxiliary light-emitting module, a light-receiving module and a light sensor module; the graphics processor is used for graphics processing; the auxiliary light-emitting module is used for auxiliary emission Visible light, the light receiving module is used to receive light, the light sensor module emits light towards the side of the warehouse handling robot and receives light reflected by obstacles, the storage unit 12 includes a semiconductor device dr...

Embodiment 3

[0029] like image 3 As shown, the traveling unit 16 includes a wheel drive motor and a walking wheel; it is used for the mobile walking of the warehouse handling robot, and the environmental monitoring module 17 includes a temperature sensing unit, a humidity sensing unit and an air pressure sensing unit, which are used to sense the location of the robot respectively. temperature, humidity and air pressure of the environment.

[0030]It should be noted that the present invention is a warehouse handling robot and its control method. When working, the remote device control unit 1 can remotely control the warehouse handling robot, receive light through the light receiving unit 13, and filter the received light according to a probability-based filtering method. The received light is filtered to determine the direction of travel of the mobile robot, and travel along the determined direction of travel, and the remote device control unit 1 can receive the control command of the robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com