Waveguide feed substrate and preparation method thereof, antenna system and preparation method thereof

A waveguide feeding and antenna system technology, which is applied in the field of communication, can solve problems such as difficult integration, poor assembly accuracy, and loss, and achieve the effects of stable antenna system structure, reduced loss and error, and high process accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

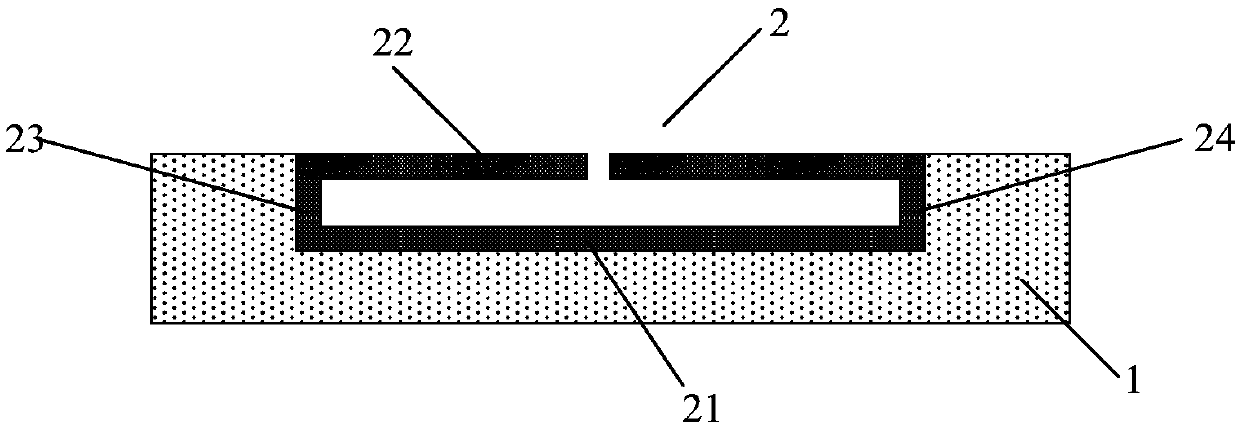

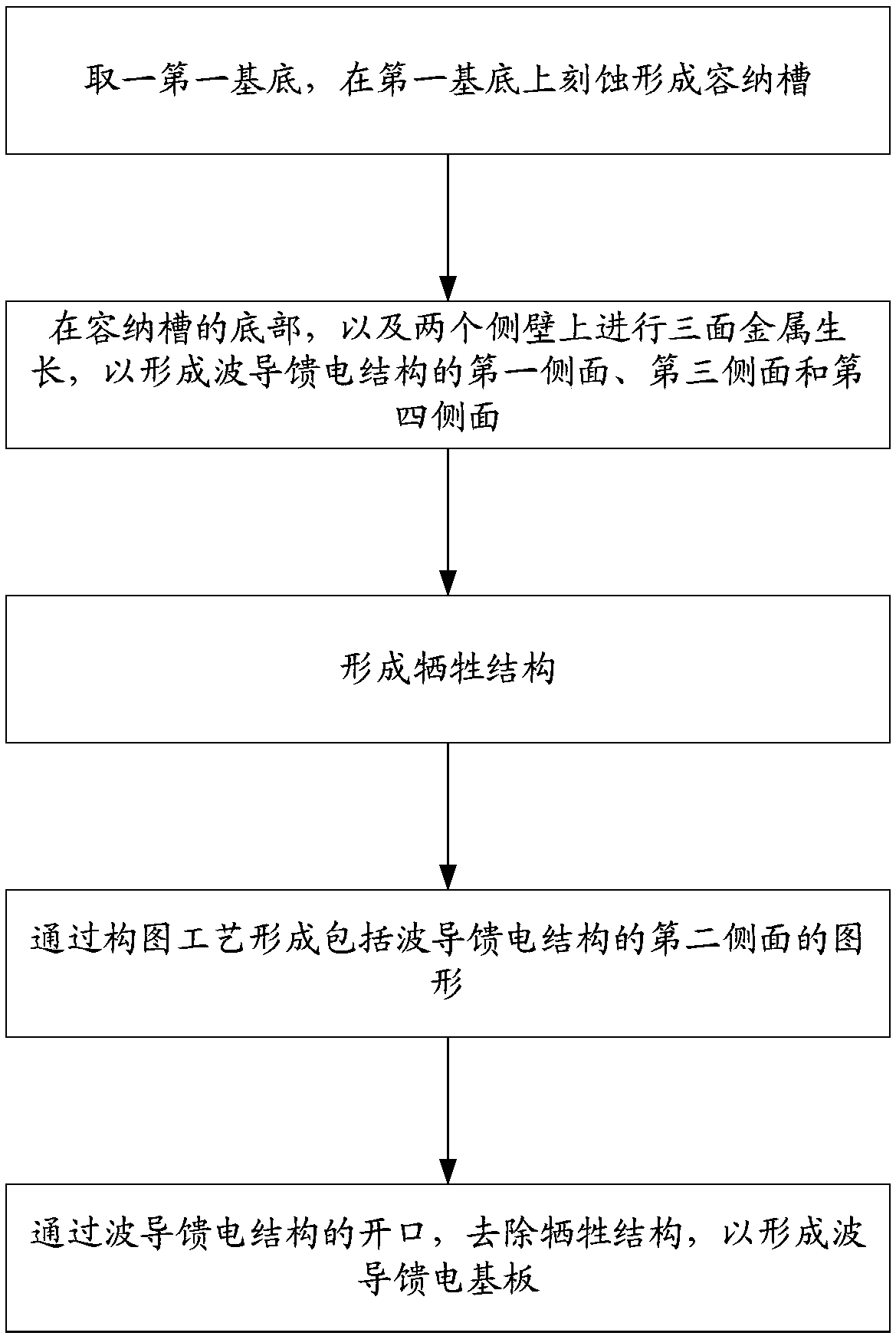

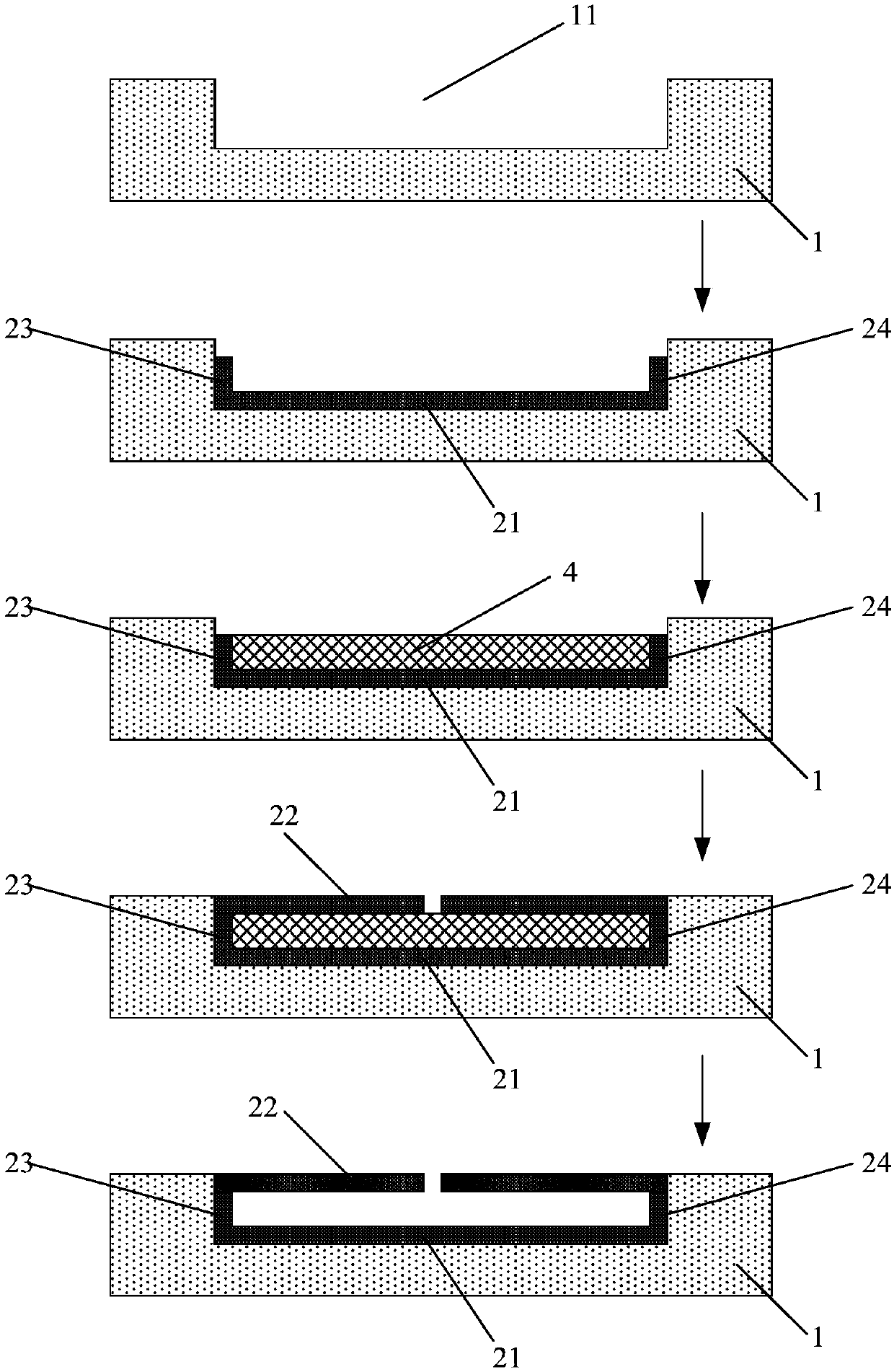

[0044] like figure 1 As shown, this embodiment provides a waveguide feeding substrate, including: a first substrate 1 and a waveguide feeding structure 2; wherein, there is a receiving groove 11 on the first substrate 1; the receiving groove 11 has a base, and is connected with the bottom The first side wall and the second side wall that are connected and oppositely arranged (that is, the receiving groove 11 is similar to a U-shaped groove); the waveguide feeding structure 2 is embedded in the receiving groove 11, and the waveguide feeding structure 2 is an internal hollow structure , which has a first surface 21 in contact with the bottom of the receiving tank, a second surface 22 opposite to the first surface 21, and a third surface 23 connected between the first surface 21 and the second surface 22 and oppositely disposed and the fourth surface 24; wherein, the third surface 23 is arranged on the first side wall of the receiving groove 11, the fourth surface 24 is arranged ...

Embodiment 2

[0069] like Image 6 As shown, this embodiment provides a waveguide feeding substrate, which is substantially the same as the waveguide feeding substrate in the embodiment, the difference is that a second surface 22 of the waveguide feeding structure 2 is provided with a second substrate.

[0070] When the waveguide feeding substrate and the antenna substrate in this embodiment are fixed together, the second substrate 3 of the waveguide feeding substrate and the substrate with the microstrip line in the antenna substrate can be fixed together through a bonding process. The precision is high, and the structure of the formed antenna system is stable, which can greatly reduce the loss and error caused by the mechanical assembly of the antenna system.

[0071] Wherein, the materials of the first substrate 1 and the waveguide feeding structure 2 in the waveguide feeding substrate of this embodiment can be the same materials as those in the first embodiment. The material of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com