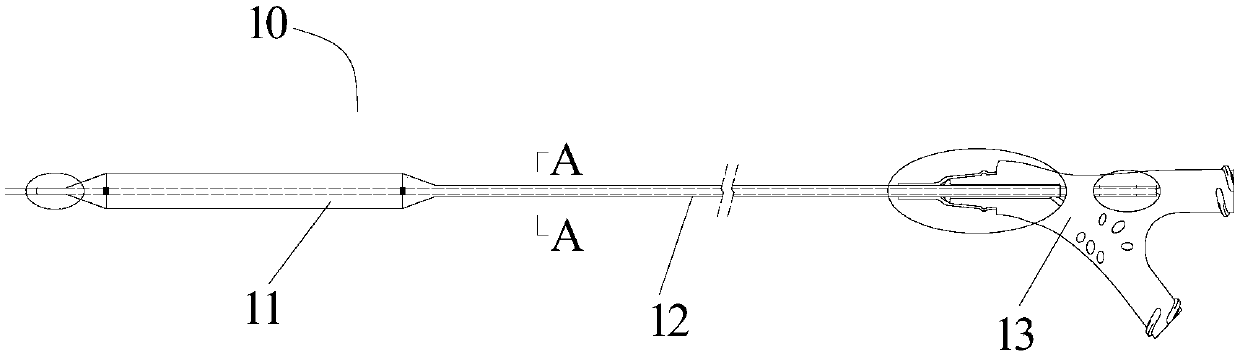

Saccule duct and preparation method thereof

A technology for balloon catheters and catheters, which is applied in the direction of balloon catheters, catheters, dilators, etc., which can solve the problems of poor catheter push performance and reduced outer tube strength, and achieve good push performance and reduce pressure relief time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The method for preparing balloon catheter of the present invention comprises the following steps:

[0027] S1. Insert the mandrel through the opening of the raw material tube, and preheat the raw material tube to a certain temperature. The preheating temperature range is 70-90°C;

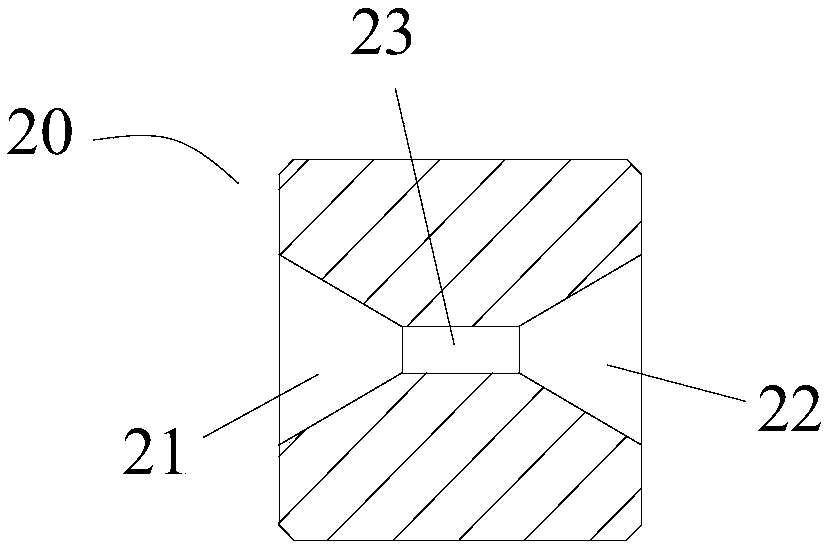

[0028] Specifically, the die 20 is assembled to the notch of the stretching machine, the mandrel is passed through the opening at the rear end of the raw material tube and passed through the opening at the front end, and then the mandrel and the raw material tube are passed through the entrance of the die 20 together. 21 penetrates into the through hole 23, and then passes through the outlet 22. Then set the heating temperature, turn on the heat source switch of the drawing machine, and preheat the die 20 loaded with the raw material tube. The heating temperature set is in the range of 70-90°C. After the die 20 is fully preheated, keep a constant temperature.

[0029] Furthermore, before t...

no. 1 example

[0041] Assemble the die 20 on the notch of the stretching machine, pass the mandrel through the rear opening of the nylon tube and not pass out from the front opening of the nylon tube, clamp the front end of the nylon tube with tweezers, and stretch about 10mm in length, The wall thickness of the front end of the nylon tube is thinned so that the front end of the nylon tube passes through the through hole 23 of the die 20 . Continue to push the mandrel so that the front end of the mandrel passes through the front end of the nylon tube. The mandrel and the nylon tube are passed through the inlet 21 of the die 20 and the front end of the nylon tube is passed through the outlet 22 . That is, the mandrel and the front end of the nylon tube pass through the through hole 23 and expose a part at the front end of the outlet 22 , and most of the rest are at the rear end of the inlet 21 .

[0042] The heating temperature is set on the heating module of the stretching machine to prehea...

no. 2 example

[0048] This embodiment differs from the first embodiment in that the heating temperature set by the heating module is 80° C., and the stretching speed is 9 mm / s.

[0049] The outer tube prepared according to the method of this example is smooth and flat, without scratches and wrinkles, with an inner diameter of 1.12 mm, an outer diameter of 1.32 mm, and a yield strength of 119.8 MPa. It does not break when wound 10 times on a round rod with a diameter of 10 mm. . Therefore, the outer tube prepared according to the method of this embodiment also meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com