Fixing unit and base fixing element

A technology of fixing components and fixing units, which is applied in the direction of connecting components, digital data processing parts, instruments, etc., can solve the problems of wasting man-hours, complicated manufacturing processes, inability to rework, wire drawing, etc., and achieve the effect of easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

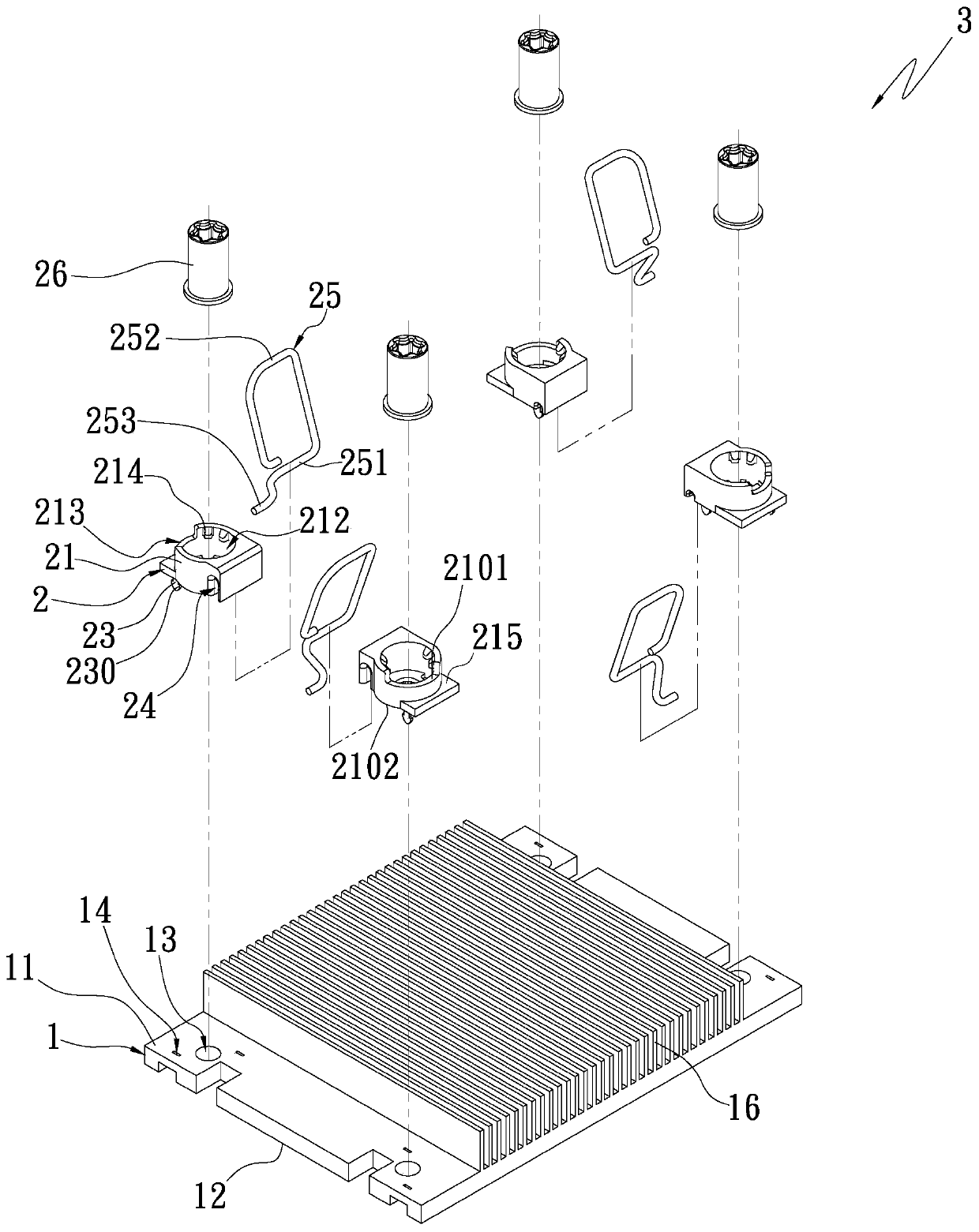

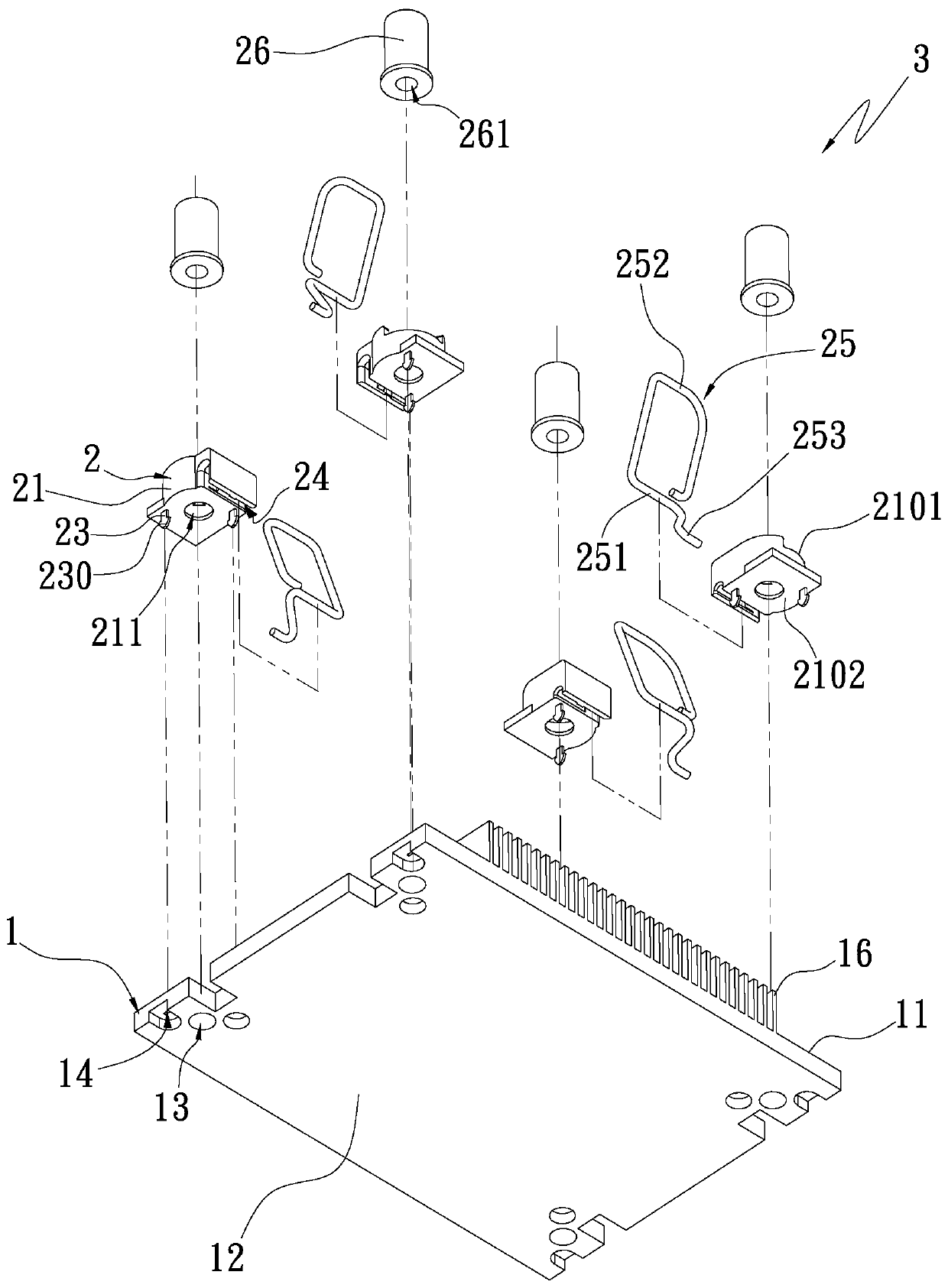

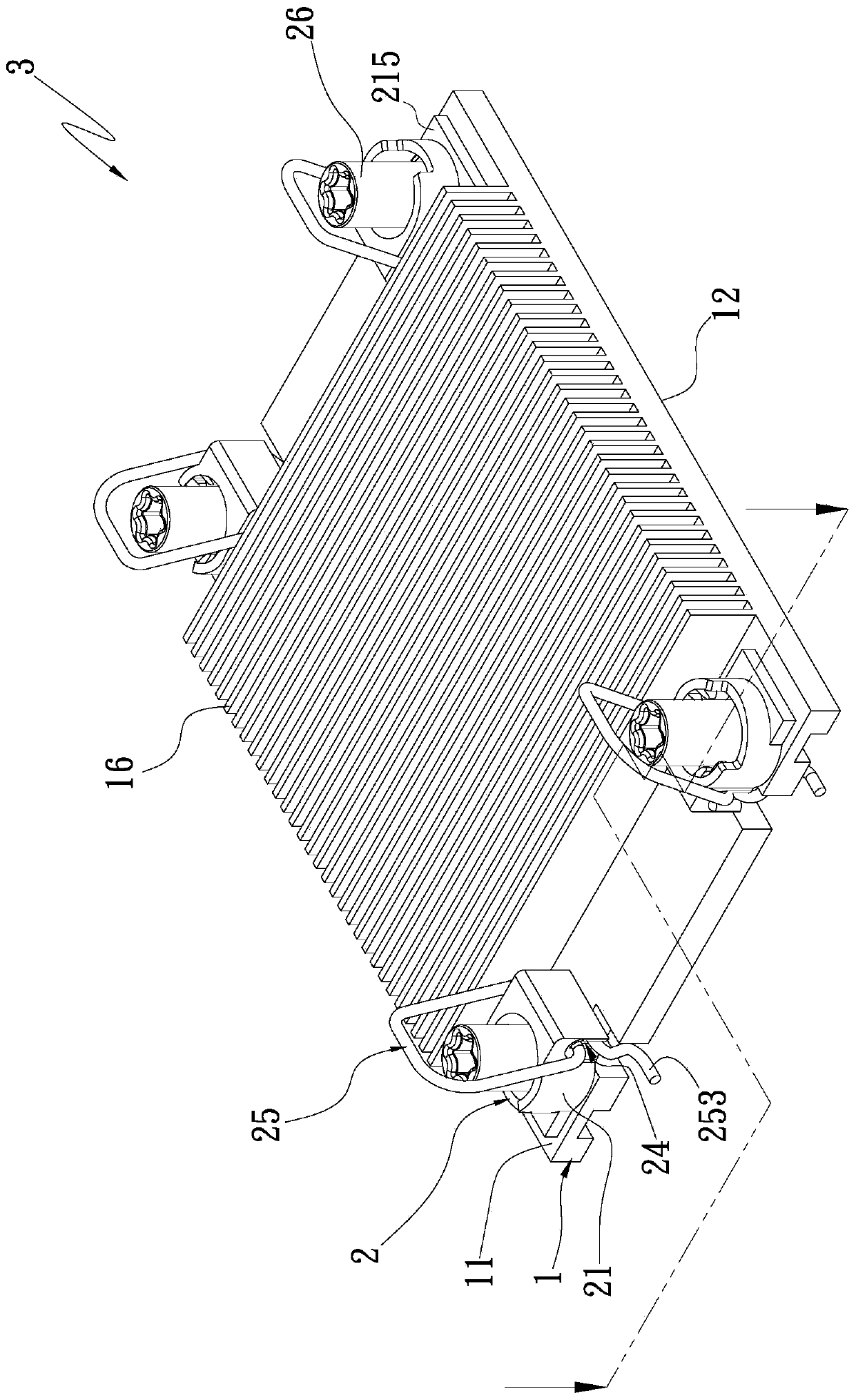

[0041] The present invention is a fixing unit and a base fixing element, please refer to Figure 1A It is a three-dimensional exploded schematic view of the first embodiment of the present invention; Figure 1B It is a perspective exploded schematic diagram of another viewing angle of the first embodiment of the present invention; figure 2 It is a three-dimensional combination schematic diagram of the first embodiment of the present invention; Figure 2A It is a partial cross-sectional schematic diagram of the first embodiment of the present invention; Figure 2B It is a partial cross-sectional schematic diagram of an embodiment of the first embodiment of the present invention. The base fixing element is applied to a solid or cavity metal (gold, silver, copper, aluminum, stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com