Manufacturing method of double-side weaving and printing combination silk muffler

A technology of combining weaving and printing and making method, which is applied to scarves, scarves, fabrics, etc., can solve the problems such as the inability to meet the matching design requirements of weaving and printing patterns, the inability to meet the requirements of light and thin texture, bright colors, and single texture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

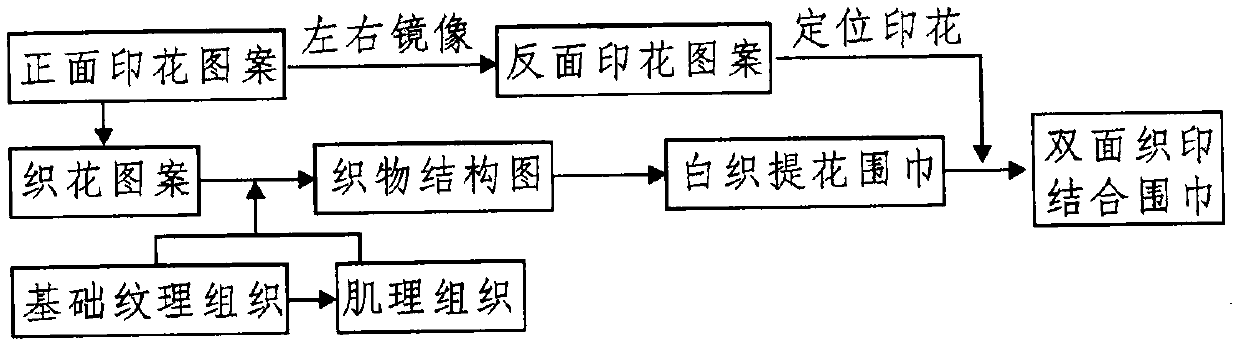

[0030] The implementation method of the present invention will be described below in conjunction with the accompanying drawings and examples.

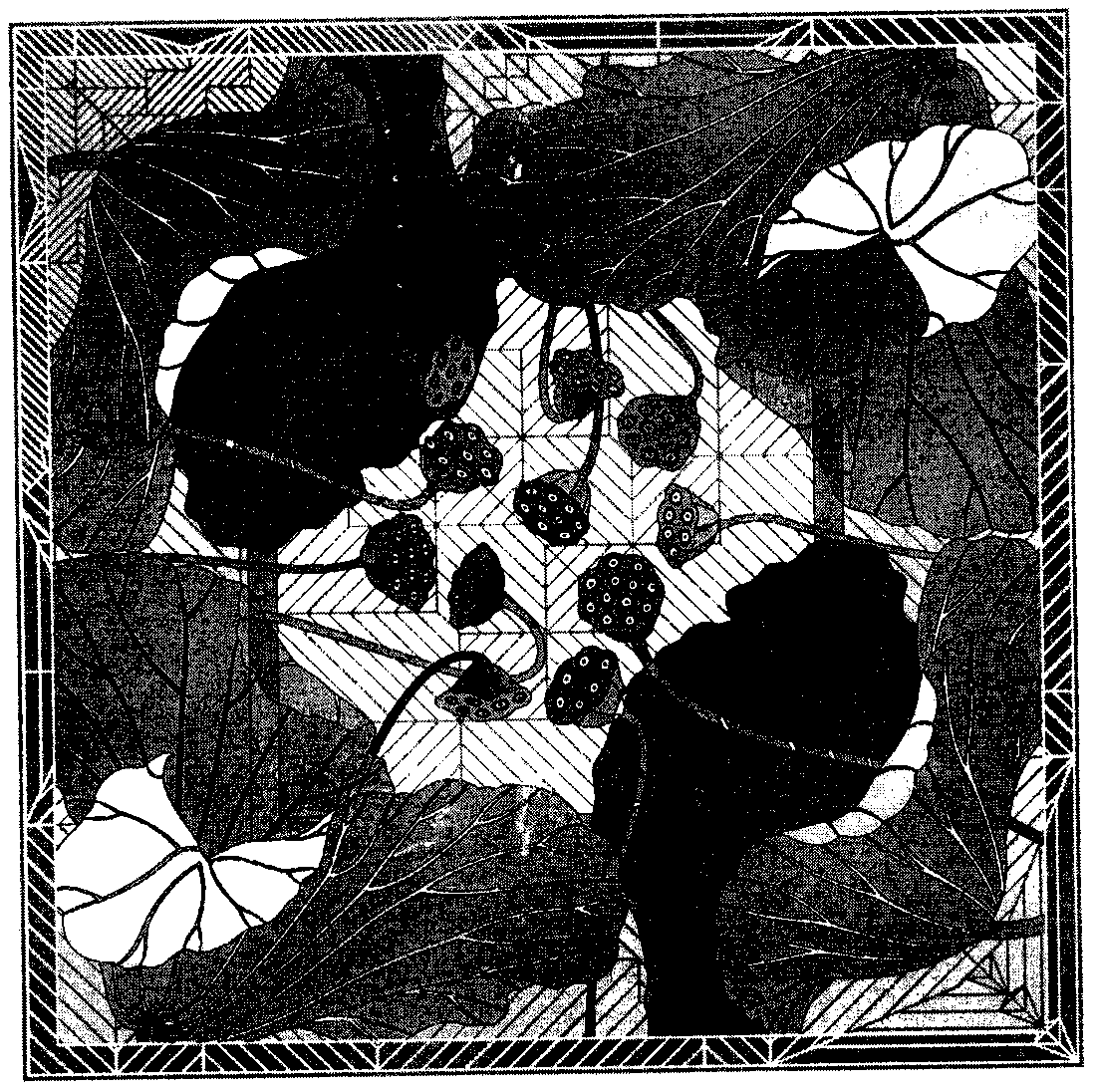

[0031] 1. Taking the design of square double-sided weaving and printing combined with silk scarf as an example, figure 2 It is a design drawing of the front printing pattern, with a side length of 52 cm;

[0032] 2. image 3 It is a design drawing of the weaving pattern for simplified design based on the printed pattern on the front;

[0033] 3. According to image 3 Design the basic texture weave with the number of colors used in the weaving flower pattern, the basic texture weave adopts the same number of weave cycles, take Rj=Rw=5, design 4 basic texture weaves, in Figure 4 shown in

[0034] 4. Figure 5 In this method, the honeycomb tissue with Rj=Rw=24 is taken as the basic tissue, the number of meridional tissue cycles remains unchanged, and the number of latitudinal tissue cycles is doubled to obtain a texture tissue with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com