Distillation condensed steam capturing device and distillation condensed steam capturing technology thereof

A distillation condensation and capture device technology, applied in the field of distillation, can solve the problems of low efficiency of the condenser, waste of cooling water, low heat exchange efficiency, etc., and achieve the effect of increasing the effective area, accelerating the convergence process, and improving the distillation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to enable those skilled in the art to better understand the technical solution of the invention, the present invention will be further described in detail below in conjunction with specific embodiments.

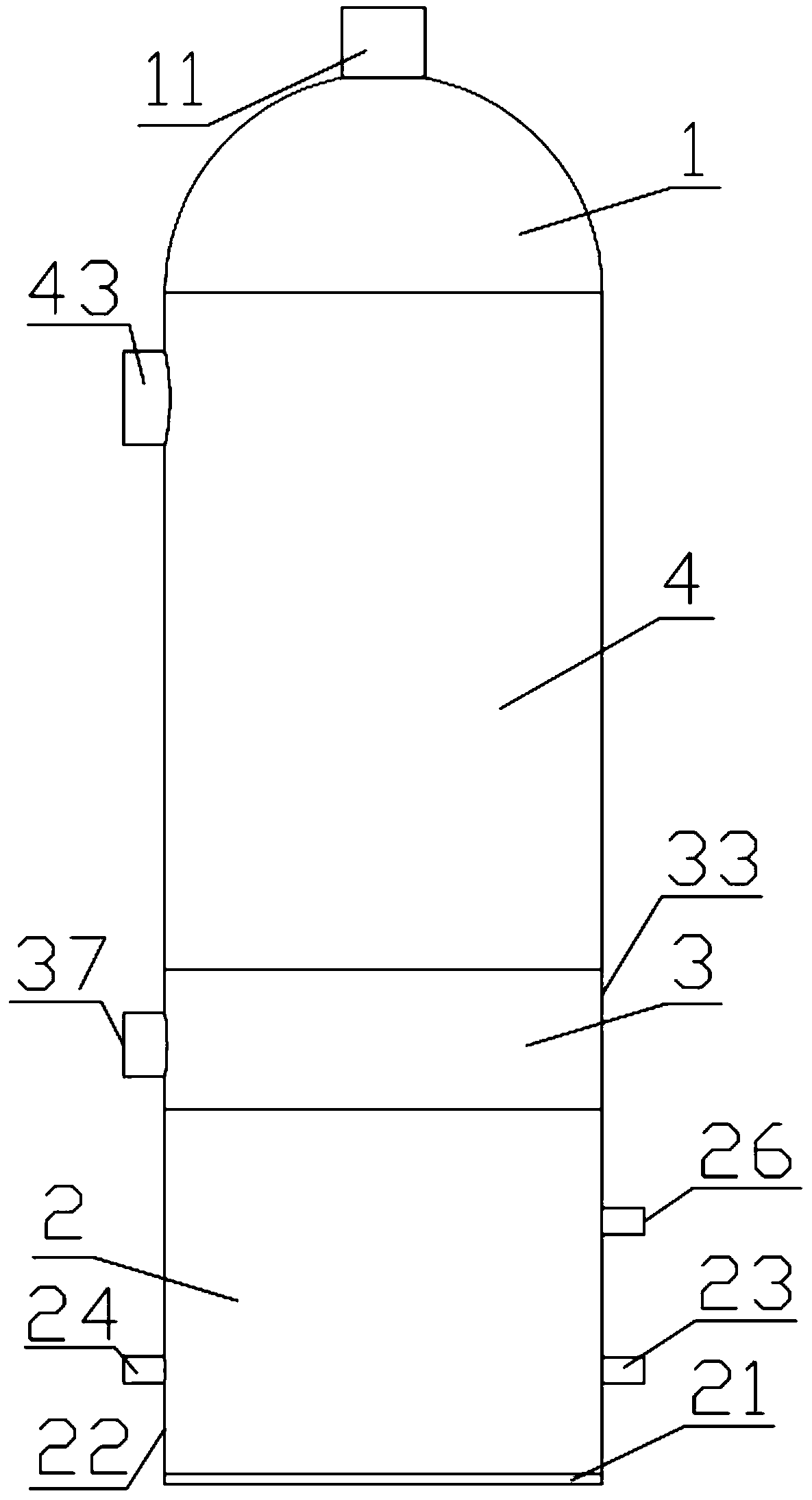

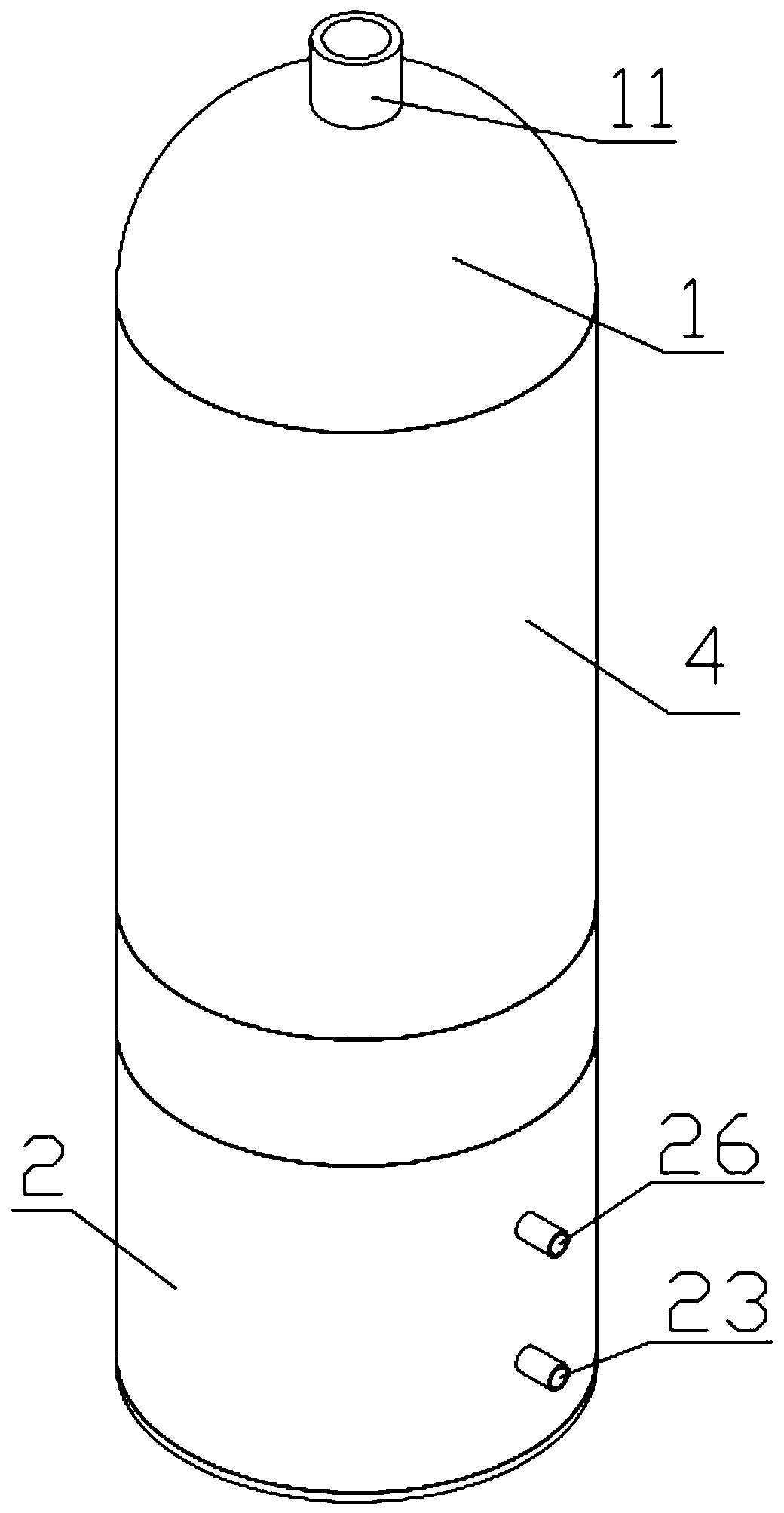

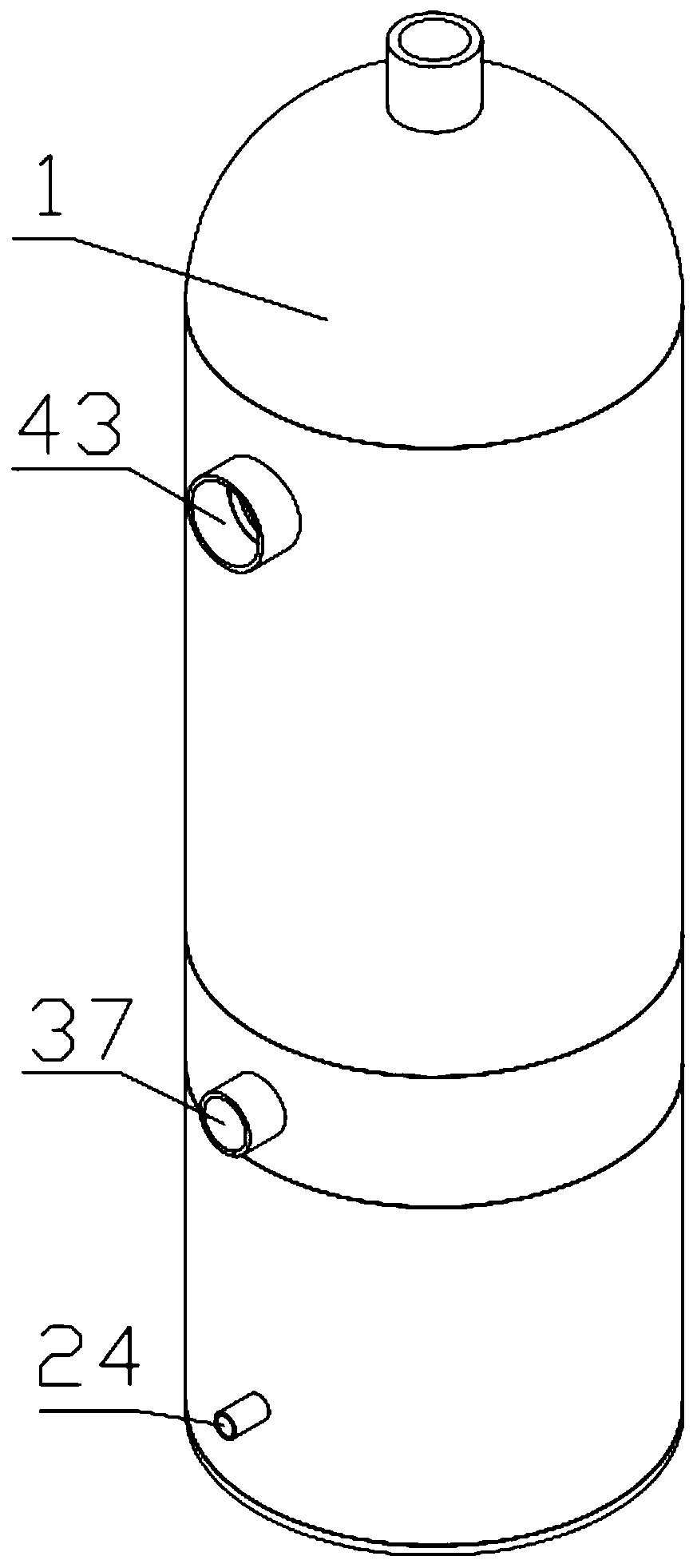

[0072] Such as Figure 1-18 Shown, the distillation condensate steam capture device of the present invention comprises:

[0073] A device top 1, the dome type is set on the top of the distillation condensation steam capture device, including:

[0074] The top outlet 11 is arranged at the center of the top 1 of the device; the top outlet 11 is preferably a tubular outlet, and the top outlet 11 is arranged at the highest point of the top of the distillation condensate steam capture device, which can increase the delivery of condensed water to the greatest extent time;

[0075] The top partition 12 is arranged at the bottom of the top 1 of the device; the top partition 12 and the shell of the top 1 of the device together form a top cavity of the device;

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com