An automatic film lamination machine and film lamination method based thereon

A film laminating machine and automatic technology, applied in the direction of cleaning method using liquid, cleaning method using tools, cleaning method and utensils, etc., can solve the problems of low automation efficiency, low film precision, low film efficiency, etc., to enhance the film precision , Improve the efficiency of filming and reduce the effect of work fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0053] The automatic film sticking machine of the present invention is mainly used for automatic film sticking of tempered film on the screens of electronic products such as mobile phones and tablet computers, and is used to enhance the precision of film sticking of electronic products, improve the efficiency of film sticking of electronic products, and replace human beings to carry out film sticking to reduce personnel. work fatigue.

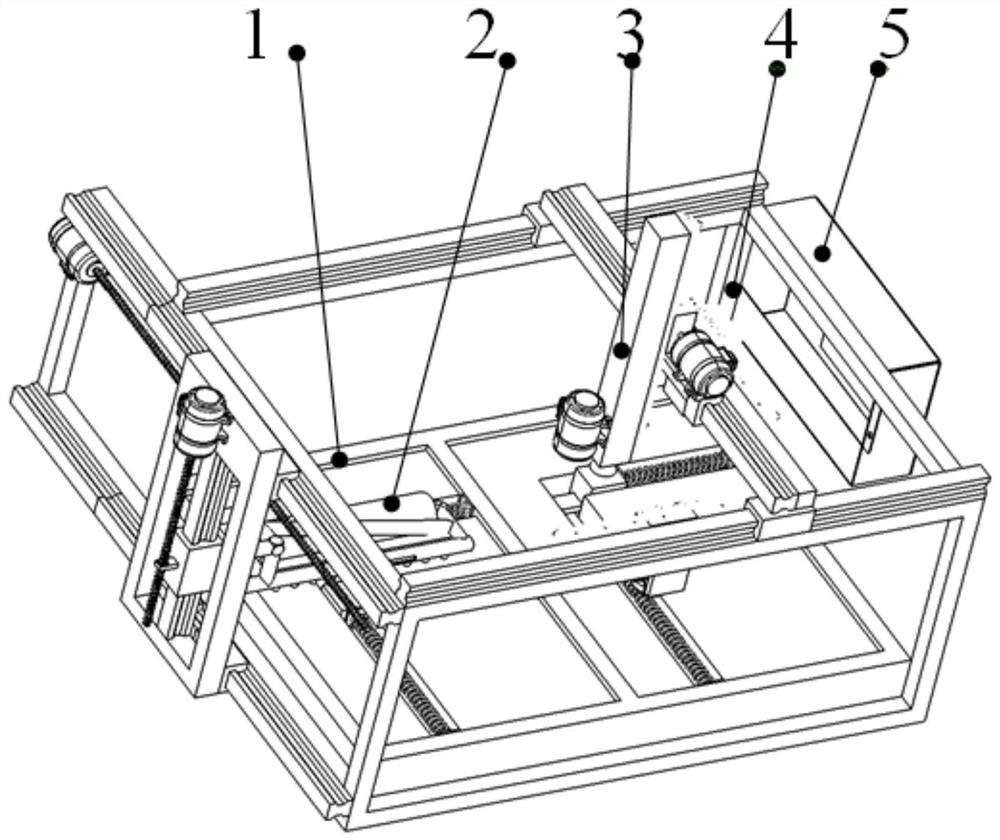

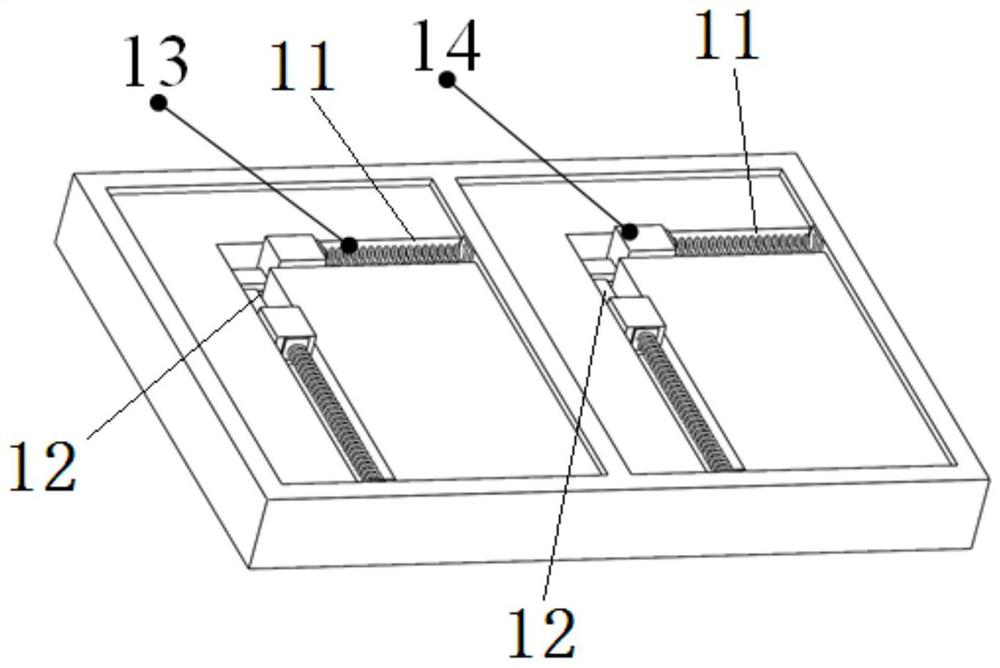

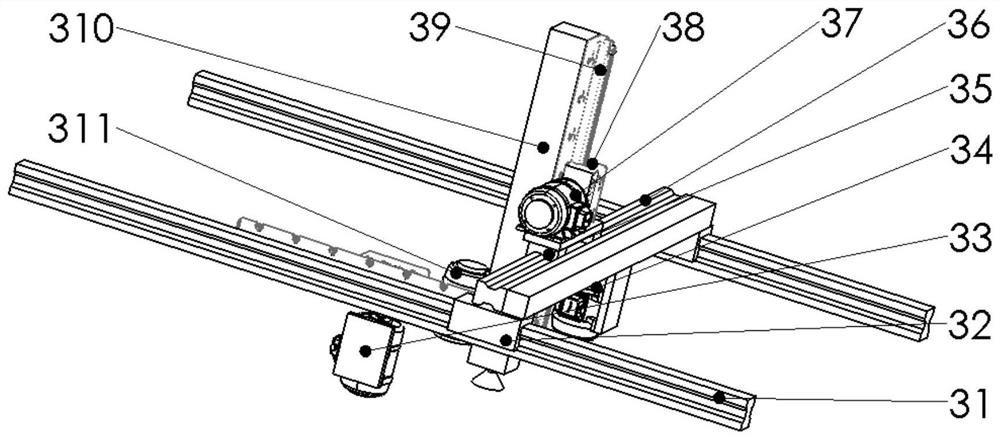

[0054] The film laminating machine is mainly composed of two parts, namely the control unit and the execution structure. Such as figure 1 As shown, the execution structure part mainly includes a frame 4 , a workbench 1 installed on the frame 4 , a wiping mechanism 2 and a mechanical arm 3 . Among them, the wiping mechanism 2 is used to clean the electronic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com