Safety energy-saving hydraulic machine

A hydraulic press and safety technology, applied in the field of hydraulic press, can solve problems such as complex design, achieve the effects of improving equipment safety, eliminating dead weight, and reducing the power and energy consumption of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

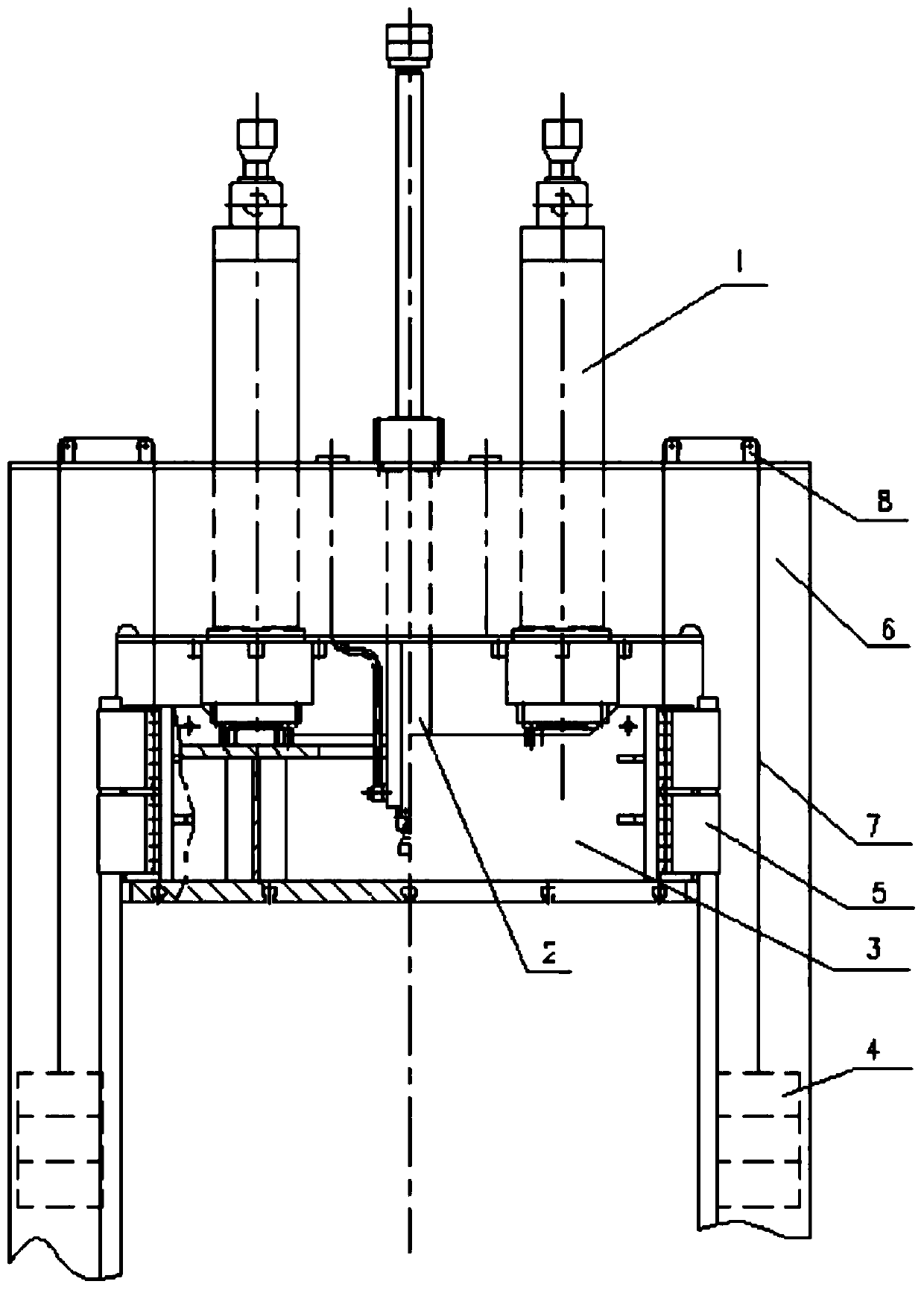

[0031] Such as figure 1 with figure 2 shown.

[0032] Taking 300t as an example, the main cylinder 1 includes two plunger cylinders. In order to meet the main tonnage requirements, the two plunger cylinders are each 150t, and are symmetrically arranged on both sides with the center line of the hydraulic press.

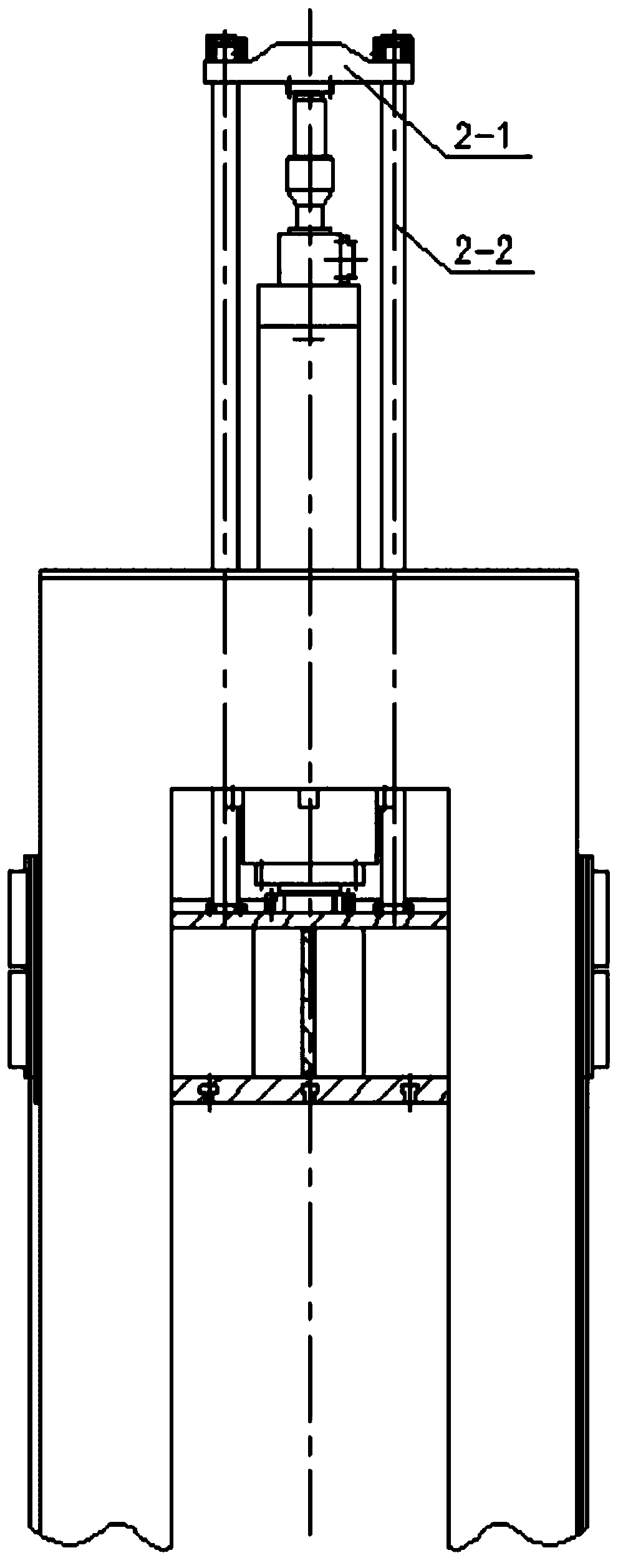

[0033] The quick cylinder 2 is located in the middle of the hydraulic press and is responsible for the quick release, demoulding and quick return of the slider 3. The size configuration of the quick cylinder 2, the maximum demoulding force is designed according to 300KN.

[0034] Both the master cylinder 1 and the fast cylinder 2 are installed on the upper beam 6 through screws, the head flange of the master cylinder 1 is connected with the slider 3, and the fast cylinder 2 is connected with the Slider 3 is connected.

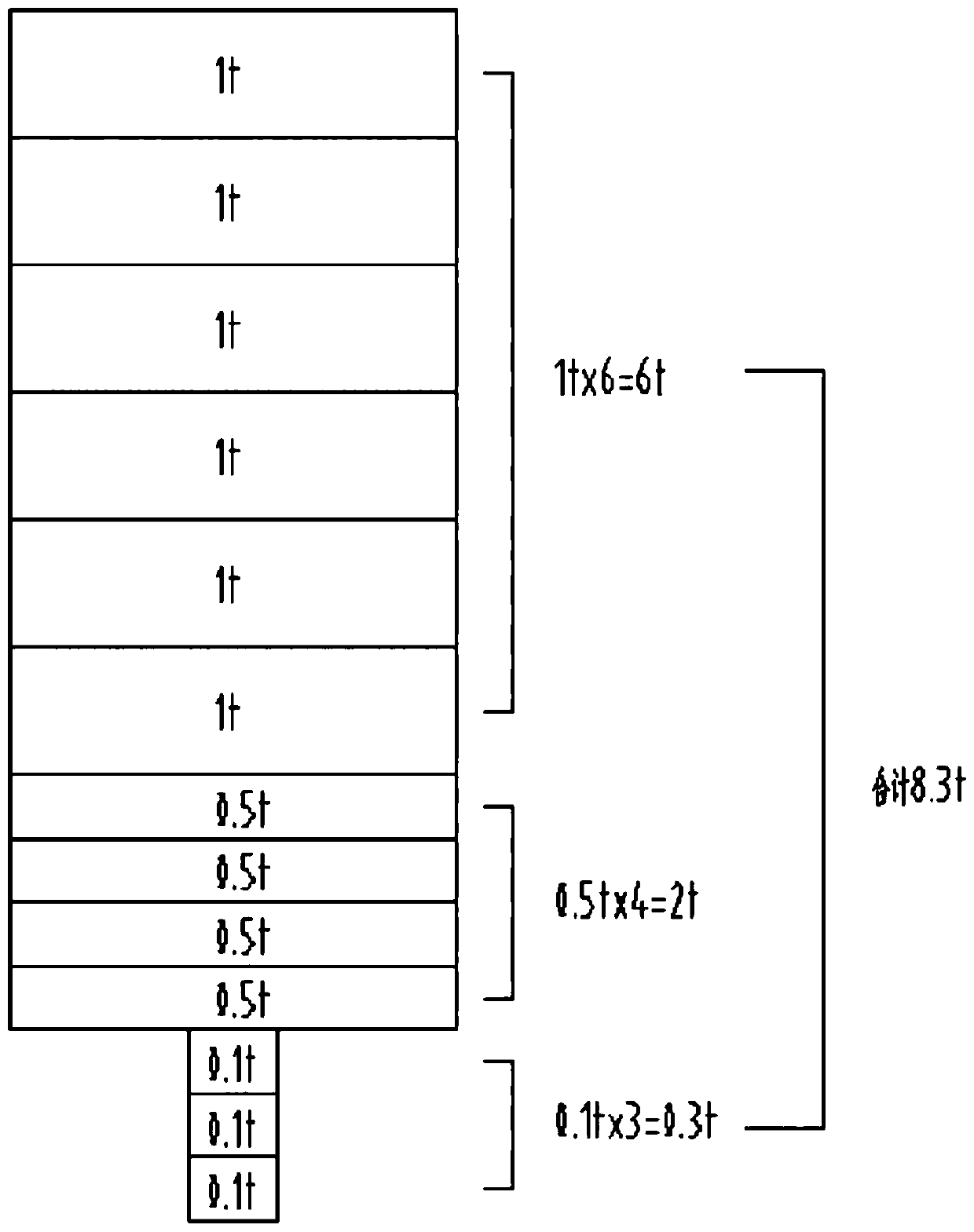

[0035] The counterweight 4 is arranged in two or four columns on both sides of the hydraulic press, and the weights of the counterweights on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com