Anti-seismic energy saving three-dimensional mortise and tenon joint net fixing one-piece cast building structure and construction method

A technology for integral pouring and housing, applied in building components, building structures, buildings, etc., can solve the problems of not being able to meet the needs of housing construction, complicated installation of prefabricated beams, and heavy prefabricated beams, saving labor and effort. , The effect of eliminating installation and dismantling and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

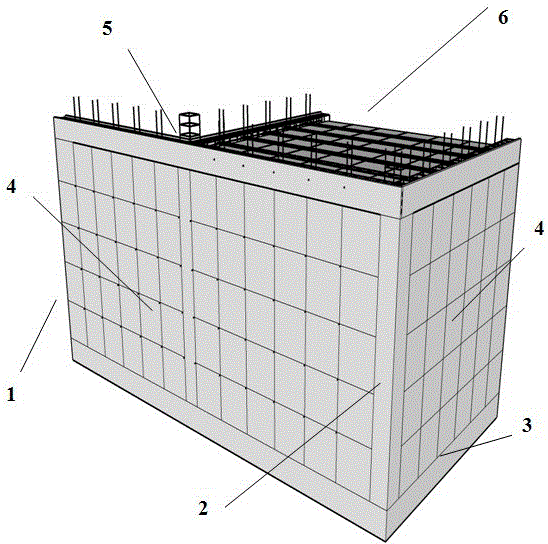

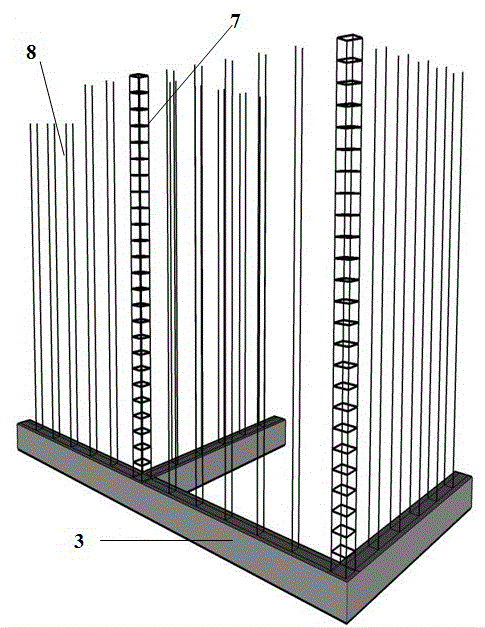

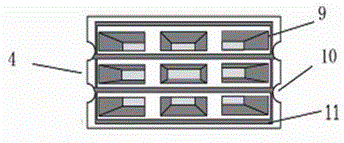

[0056] figure 1 is the invention three Dimensional tenon-tenon net-solid integral pouring house overall structure; as shown in the figure, the overall house structure of the present invention is composed of net-solid shear wall 1, column 2, bottom ring beam 3, tenon-tenon brick 4, top ring beam 5 and floor slab 6 Constructed integral pouring houses. Its technical feature is that the grid-fixed shear wall 1 is formed by combining and installing the mortise and tenon brick 4 of the present invention. The mortise and tenon groove structure of the mortise and tenon brick 4 enables the shear wall to be supported by horizontal and vertical steel bars, and the grid is formed by pouring light concrete slurry. shear wall.

[0057] The top ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com