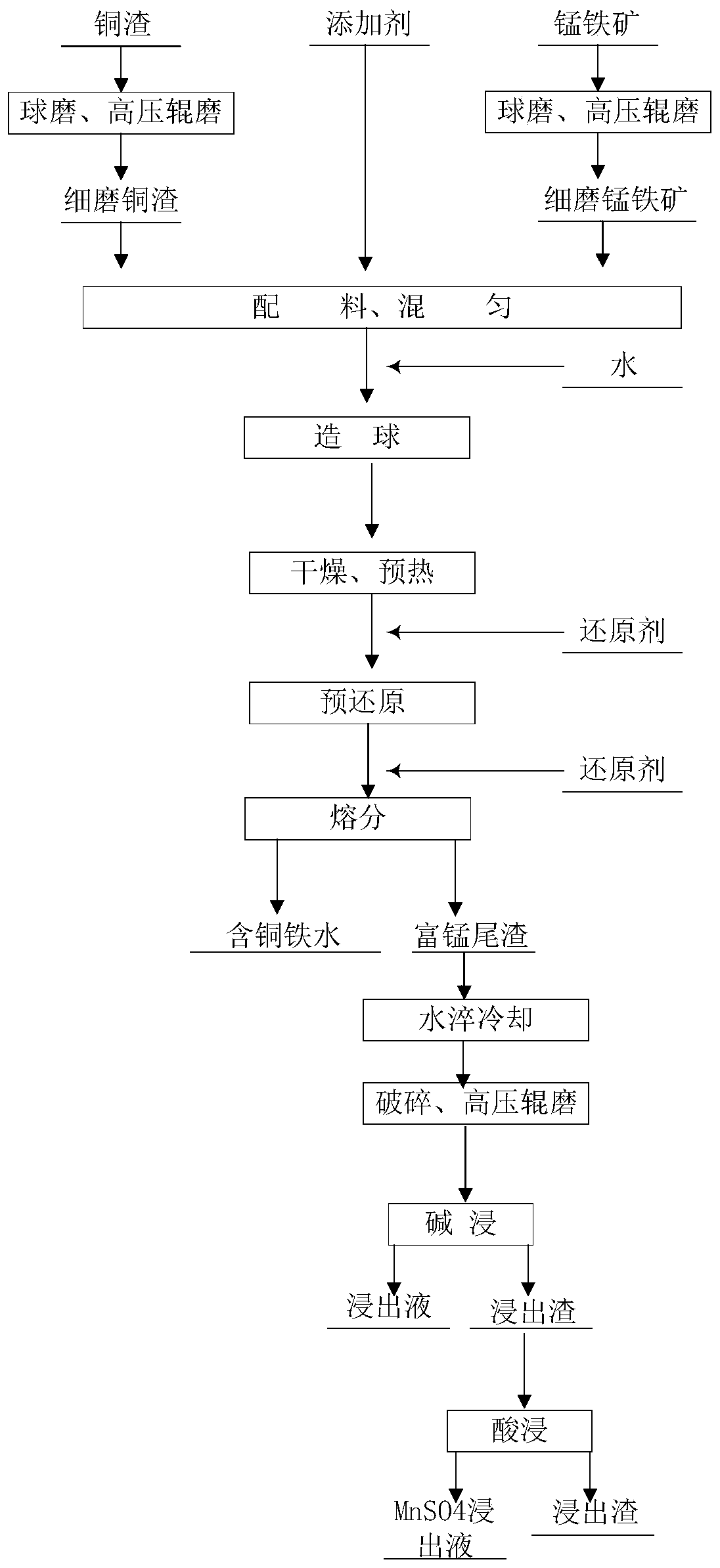

A method for recovering iron, copper and manganese through co-reduction of copper smelting slag and ferromanganese ore

A technology of copper smelting slag and ferromanganese ore, which is applied in the field of co-reduction of copper smelting slag and ferromanganese ore to recover iron, copper and manganese, can solve the problems of less than 1% iron utilization rate and large environmental pollution of coking process, and achieve improvement Effects of improving slag fluidity, improving reduction kinetic conditions, and improving green pellet quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The copper slag is treated by ball milling and high-pressure roller milling until more than 85% of the particles have a particle size of less than 0.074mm and a specific surface area of 1630cm 2 / g; the iron-manganese ore is combined with ball milling and high-pressure roller milling until more than 80% of the particles have a particle size of less than 0.074mm and a specific surface area of 1530cm 2 / g; mix the copper slag and the iron-manganese ore at a ratio of 4:6, and add 15% additives (limestone 70wt% + sodium humate 30wt%), use a disc pelletizer to pellet the mixture, and control the pelletizing moisture to 7.5% , the ball making time was 13min, the drop strength of the obtained green balls was 5.3 times / 0.5m, the compressive strength of the green balls was 11.4N / piece, and the green ball burst temperature was 315°C; After drying at 300°C for 6 minutes and preheating at 1100°C for 14 minutes, the compressive strength of the preheated pellets is 750N / piece; th...

Embodiment 2

[0061] The copper slag is treated by ball milling and high-pressure roller milling until more than 85% of the particles have a particle size of less than 0.074mm and a specific surface area of 1630cm 2 / g; the iron-manganese ore is combined with ball milling and high-pressure roller milling until more than 80% of the particles have a particle size of less than 0.074mm and a specific surface area of 1530cm 2 / g; mix the copper slag and iron-manganese ore at a ratio of 5:5, and add 15% additives (limestone 70wt% + sodium humate 30wt%), use a disc pelletizer to pellet the mixture, and control the pelletizing moisture to 7.5% , the ball making time was 12min, the drop strength of the obtained green balls was 5.5 times / 0.5m, the compressive strength of the green balls was 11.9N / piece, and the green ball burst temperature was 355°C; After drying at 350°C for 5 minutes and preheating at 1100°C for 13 minutes, the compressive strength of the preheated pellets is 825N / piece; the ho...

Embodiment 3

[0066] The copper slag is treated by ball milling and high-pressure roller milling until more than 85% of the particles have a particle size of less than 0.074mm and a specific surface area of 1630cm 2 / g; the iron-manganese ore is combined with ball milling and high-pressure roller milling until more than 80% of the particles have a particle size of less than 0.074mm and a specific surface area of 1530cm 2 / g; mix the copper slag and iron-manganese ore at a ratio of 5:5, add 25% additives (limestone 80wt% + sodium humate 20wt%), use a disc pelletizer to pellet the mixture, and control the pelletizing moisture to 7.5% , the ball making time was 14min, the drop strength of the obtained green balls was 5.8 times / 0.5m, the compressive strength of the green balls was 12.7N / piece, and the green ball burst temperature was 375°C; After drying at 350°C for 6 minutes and preheating at 1100°C for 15 minutes, the compressive strength of the preheated pellets is 875N / piece; the hot pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com