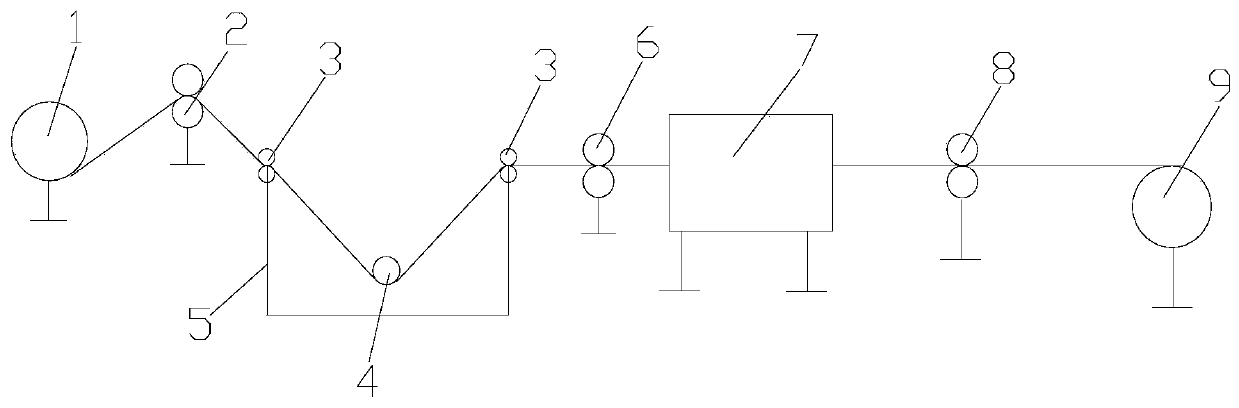

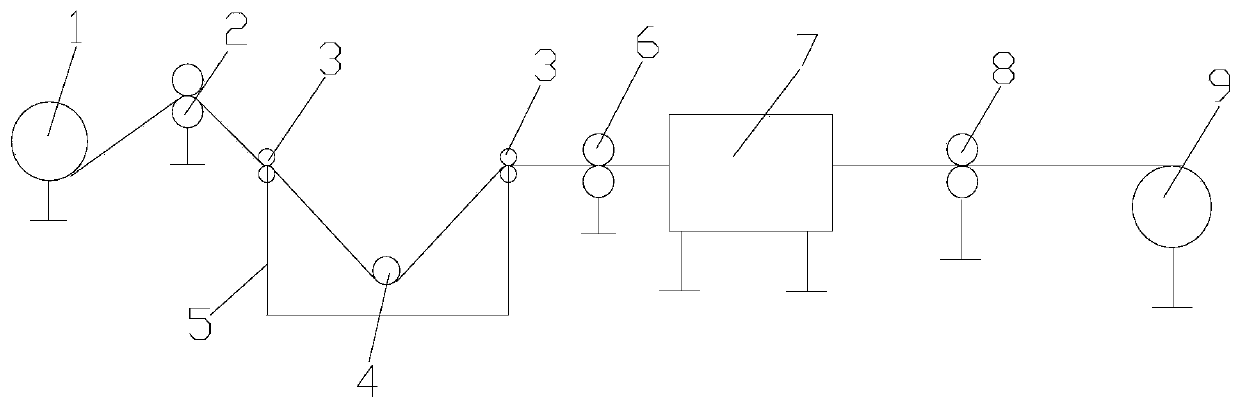

Preparation method and preparation device of wear-resistant decorative paper

A technology for preparing equipment and decorative paper, which is applied in the field of papermaking equipment, can solve problems such as wear and loss of decorative paper, and achieve the effects of not being easy to wear, prolonging service life, and increasing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of impregnation suspension glue, with 100 parts of alumina powder, 1500 parts of deionized water, 1 part of dispersant, 10 parts of silica nanoparticles, 10 parts of titanium dioxide nanoparticles, 60 parts of polyurethane, 200 parts of acrylic resin, 5 parts Cross-linking agent and 2 parts of penetrant are heated to 60°C and stirred for 20 minutes to mix well, then cooled to 25°C for later use.

Embodiment 2

[0028] A kind of impregnation suspension glue, with 50 parts of alumina powder, 1000 parts of deionized water, 3 parts of dispersant, 20 parts of silica nanoparticles, 20 parts of titanium dioxide nanoparticles, 120 parts of polyurethane, 200 parts of acrylic resin, 7 parts Cross-linking agent and 5 parts of penetrant were heated to 65°C and stirred for 15 minutes to mix well, then cooled to 30°C for later use.

Embodiment 3

[0030] A kind of impregnation suspension glue, 50 parts of alumina powder, 500 parts of deionized water, 2 parts of dispersant, 15 parts of silica nanoparticles, 10 parts of titanium dioxide nanoparticles, 90 parts of polyurethane, 200 parts of acrylic resin, 7 parts Cross-linking agent and 3 parts of penetrant were heated to 50°C and stirred for 30 minutes to mix well, then cooled to 28°C for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com