Sleeve extrusion type aerofoil-expanded anchor rod

An extrusion and sleeve technology, applied in sheet pile walls, excavation, construction, etc., can solve the problems of waste of steel resources, increase in support costs, increase in loss of mechanical equipment, etc., to save steel, improve utilization, increase Effect of large anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

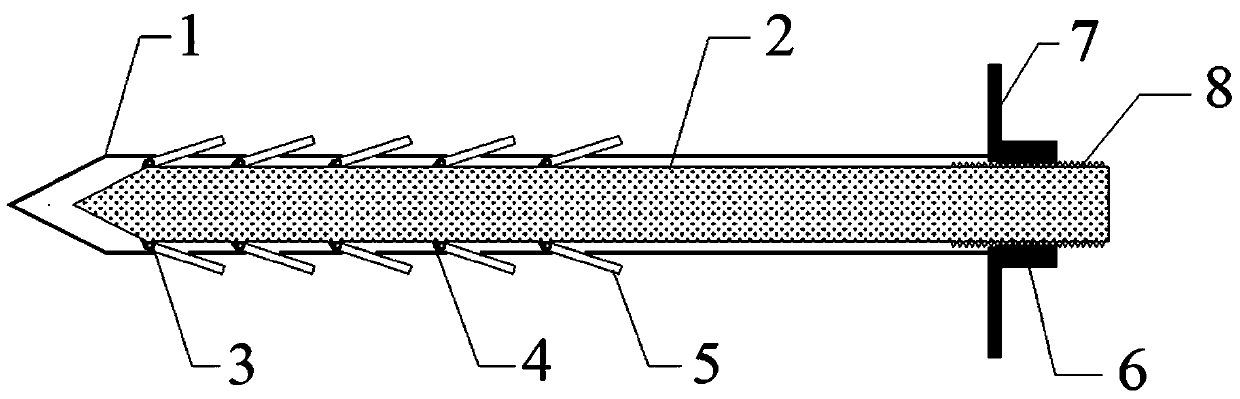

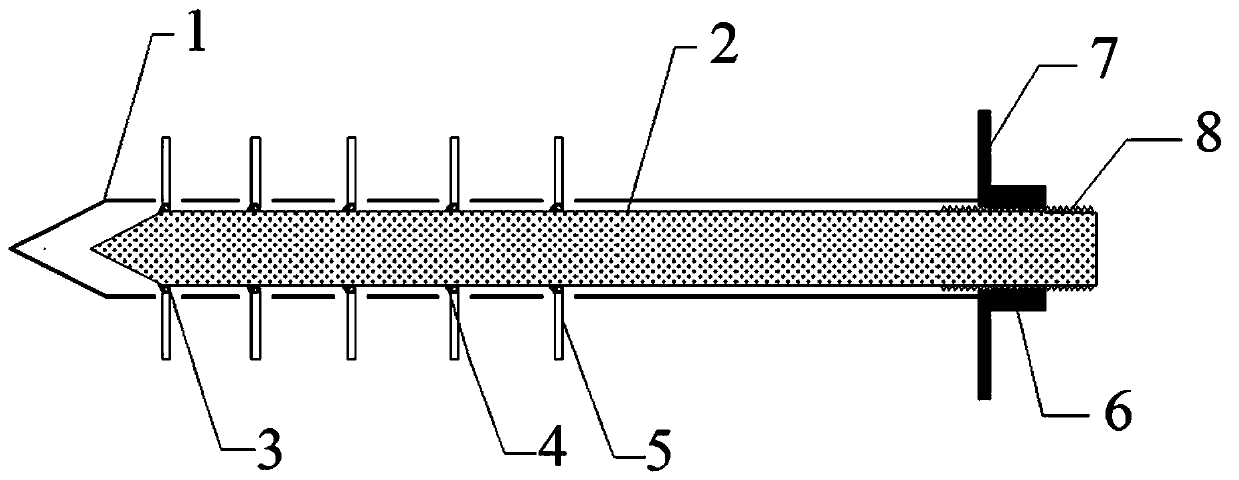

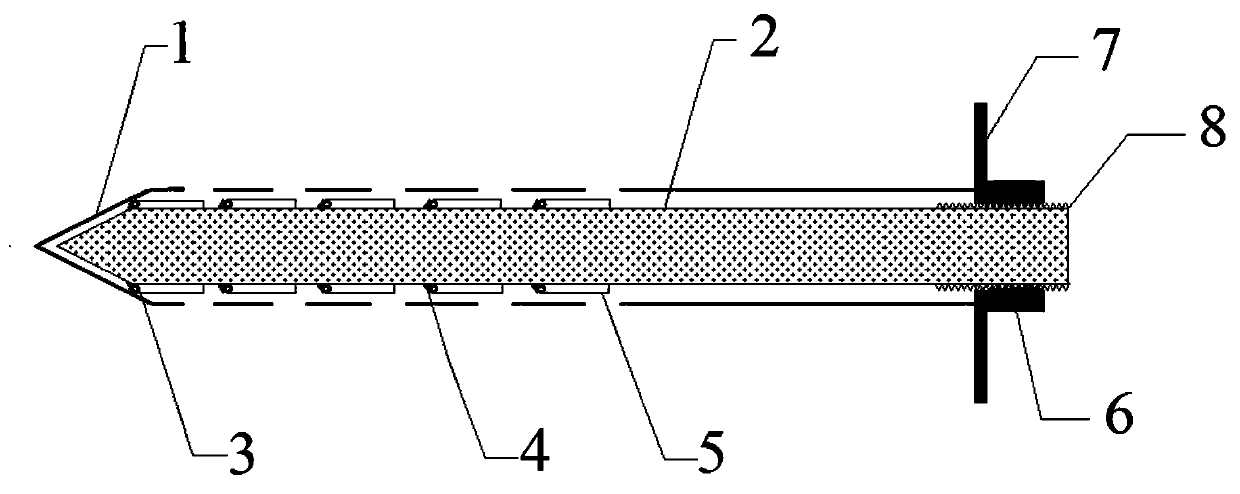

[0035] As shown in the figure, the present invention includes a sleeve 1, a main rod 2, a pin shaft 3, a baffle plate 4, an airfoil plate 5, a nut 6 and a pressure ring 7, the main rod 2 is placed in the sleeve 1, and the main rod 2 is front The side wall of the upper part is connected with the airfoil plate 5 through the pin shaft 3, the sleeve 1 is provided with a wing plate through hole, the rear end of the sleeve 1 has a pressure ring 7, and the main rod 2 passes through the center hole of the pressure ring 7; A nut 6 is arranged at the rear, and an external thread 8 cooperating with the nut 6 is arranged at the rear end of the main rod; an airfoil 5 limiting baffle 4 is arranged on the main rod 2 at the front end of the pin shaft 3 .

[0036] The airfoil 5 adopts steel plate.

[0037] Multiple sets of airfoil plates 5 are evenly distributed along the length direction of the main pole 2 , and each set of airfoil plates 5 includes a plurality of airfoil plates 5 uniformly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com