High energy consumption damping wall

A damping wall, high energy consumption technology, applied in the field of high-rise structure vibration reduction, can solve problems such as limited, achieve the effect of reversible process and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

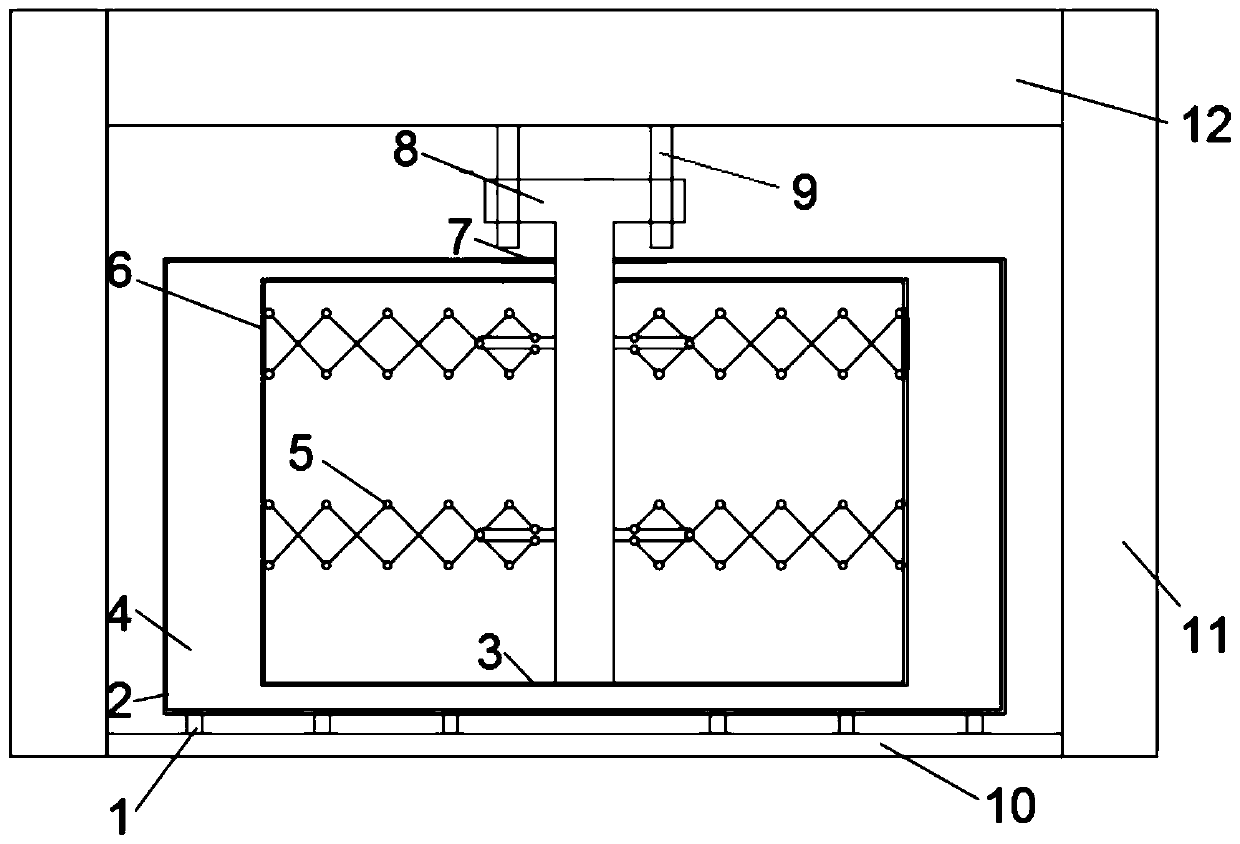

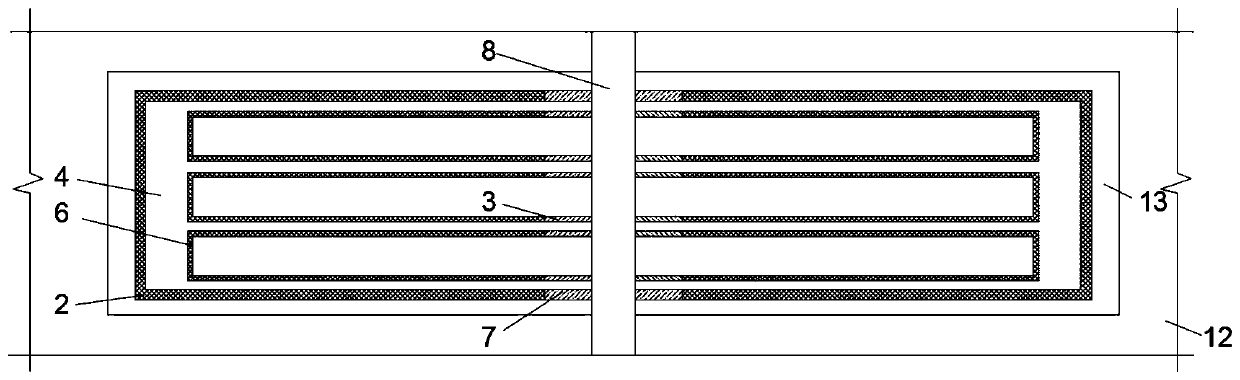

[0032] Embodiment 1: as figure 1 , figure 2 As shown, the present invention includes a high energy consumption damping wall, including a damping plate outer frame, a damping plate and a T-shaped structure arranged in the wall;

[0033] The outer frame of the damping plate 2, the lower part is fixed on the lower floor 10 through the connector I1;

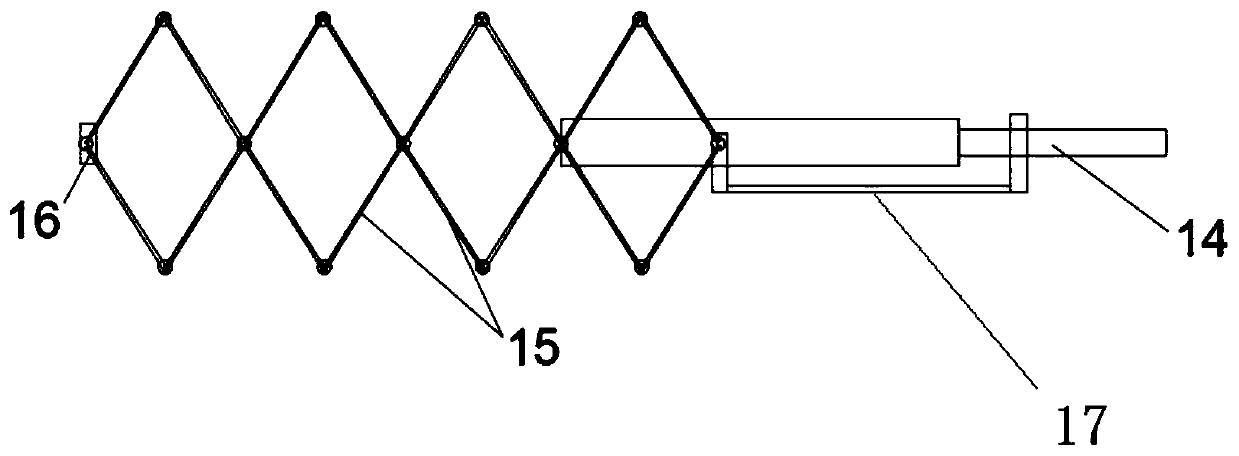

[0034] A plurality of damping plates 6 are arranged in the outer frame of the damping plate 2. In this example, three damping plates 6 are arranged in parallel, and a working chamber 4 is formed in the outer frame of the damping plate 2 and between the adjacent damping plates 6. The working chamber 4 The inside is filled with a shear thickening liquid; several scissor mechanisms 5 are arranged inside each damping plate;

[0035] T-shaped structure 8, the upper horizontal part is fixed on the lower main beam 12 of the upper floor through the connector II9, the lower vertical part penetrates the damping plate frame 2 and the damping...

Embodiment 2

[0042] Embodiment 2: The difference between this example and Embodiment 1 is: the wall structure in this example: 240mm×6000mm×3600mm, 2 damping plates are arranged in it, the distance between the inner adjacent damping plates 6 of the outer frame 2 and The distance between the edge damping plate and the outer frame of the damping plate is 2.0 mm; the scissor mechanism 5 arranged in the damping plate 6 is two symmetrical rows, and the relative speed of the high-rise building layer is multiplied by the scissor mechanism 5 (this example uses magnified by 5 times or more), at this time, the STF inside the working chamber 4 will be squeezed at a relatively high rate by the damping plate 6 and flow into the gap of the damping plate 6, and the STF will rapidly undergo shear thickening during this process Effect, generate damping force, so as to realize the vibration reduction and energy consumption of high-rise building structures, and achieve the vibration reduction effect.

Embodiment 3

[0043] Embodiment 3: The difference between this example and Embodiment 1 is: the wall structure in this example: 300mm × 6300mm × 3900mm in which 3 damping plates are arranged, the distance between the inner adjacent damping plates 6 of the outer frame 2 and the edge The distance between the damping plate and the outer frame of the damping plate is 1.0mm; the scissor mechanism 5 arranged in the damping plate 6 is two symmetrical rows, and the relative velocity of the high-rise building layer is multiplied by the scissor mechanism 5. In this example, the magnification 8 times, realize the vibration reduction and energy consumption of high-rise building structures, and achieve the vibration reduction effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com