Decorative curtain wall structure

A technology of curtain wall and power parts, applied in the direction of walls, building components, building structures, etc., can solve the problems of thieves, high-rise unsafe, troublesome, etc., to achieve the effect of improving service life, no theft and safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

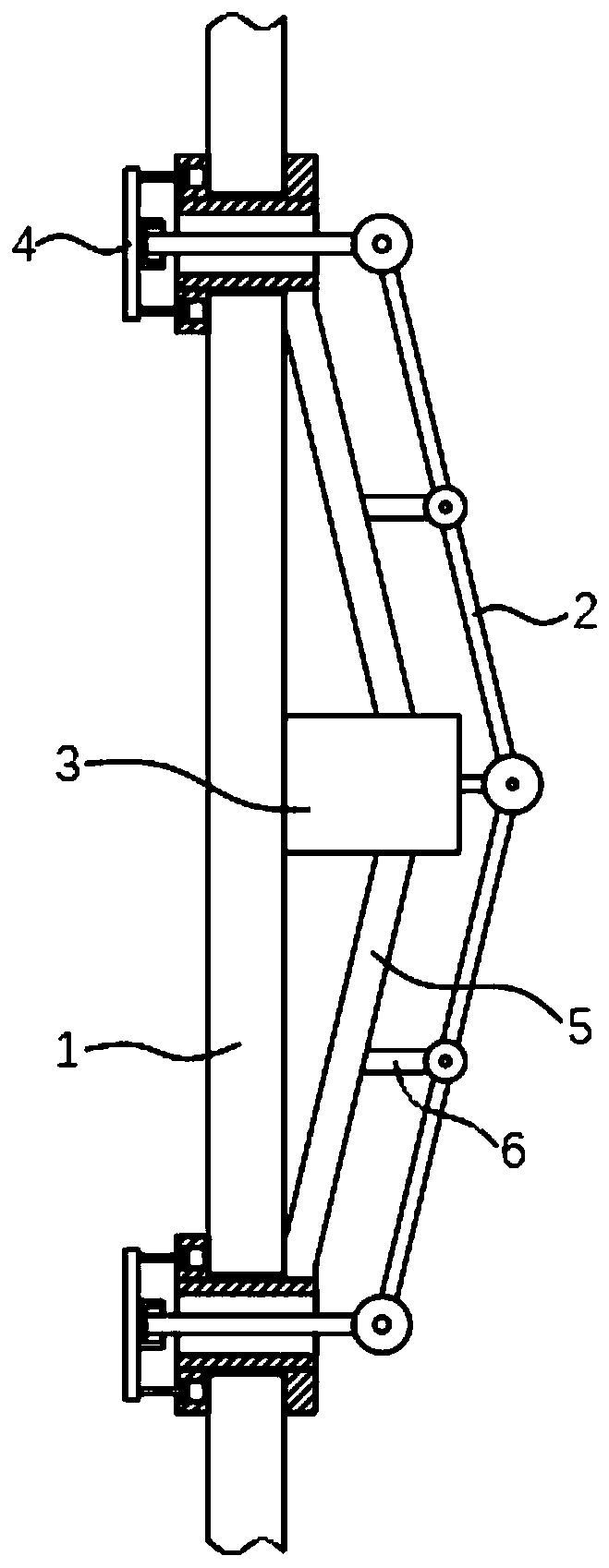

[0028] refer to Figure 1 to Figure 3 , the decorative curtain wall structure includes a power part 3 and a cantilever 5; the cantilever 5 is used to fix the power part 3 and the ventilation fixing part 4.

[0029] The number of the cantilever 5 is multiple, the head of the cantilever 5 is arranged equidistantly along the circumference of the power part 3, and the casing of the cantilever 5 and the power part 3 is integrally formed;

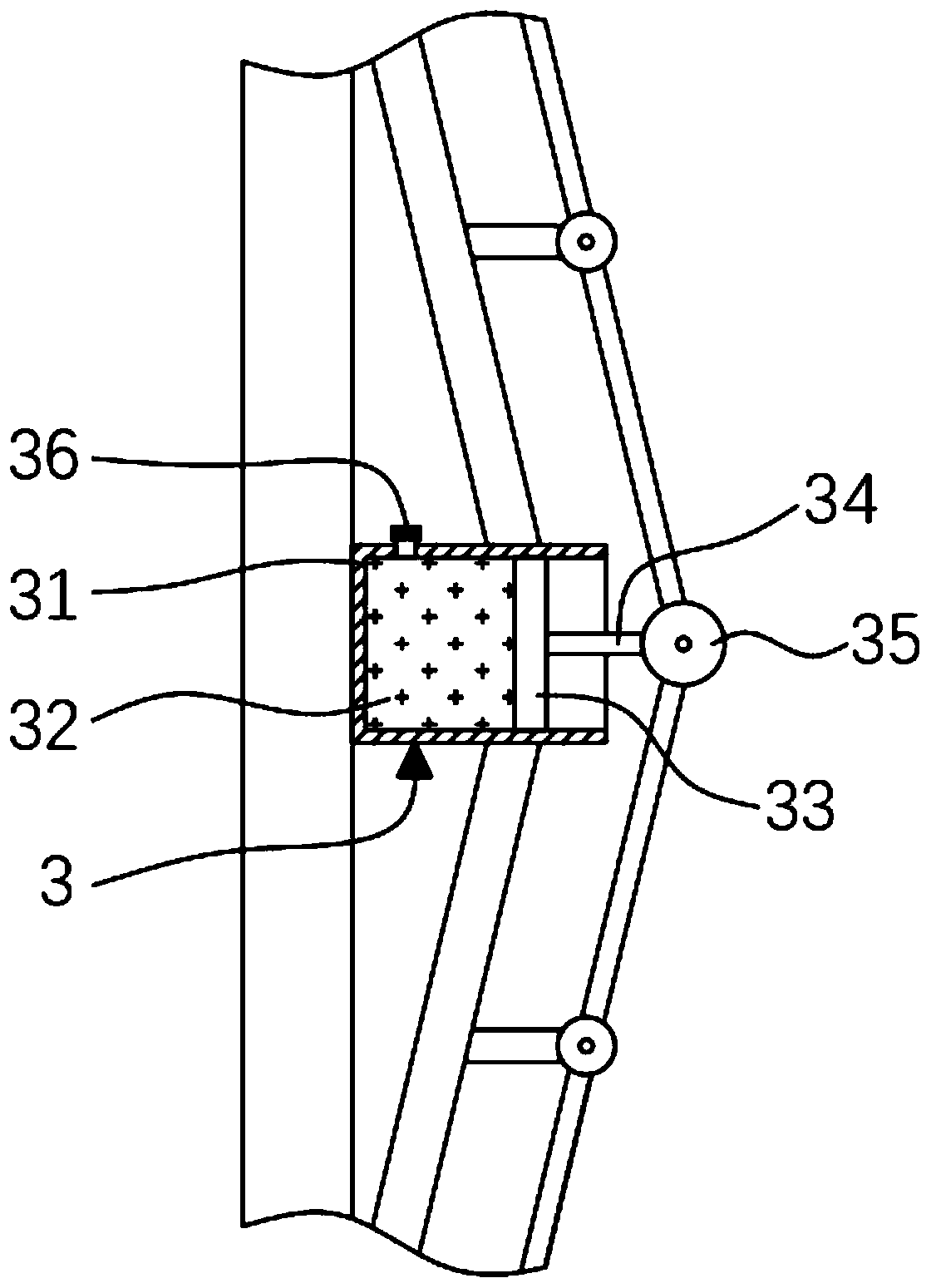

[0030] refer to figure 2 , the power part 3 includes a housing 31, a piston 33, a piston rod 34, a connecting joint 35 and a fluid supply tube 36, and the specific connection methods are as follows:

[0031] The casing 31 is filled with condensate 32, the piston 33 is arranged radially on the inner surface of the casing 31, and the outer diameter of the piston 33 is equal to the inner diameter of the casing 31, and the middle part of the outer side of the piston 33 is fixedly connected with the piston rod 34 , the side of the piston rod 34 awa...

Embodiment 2

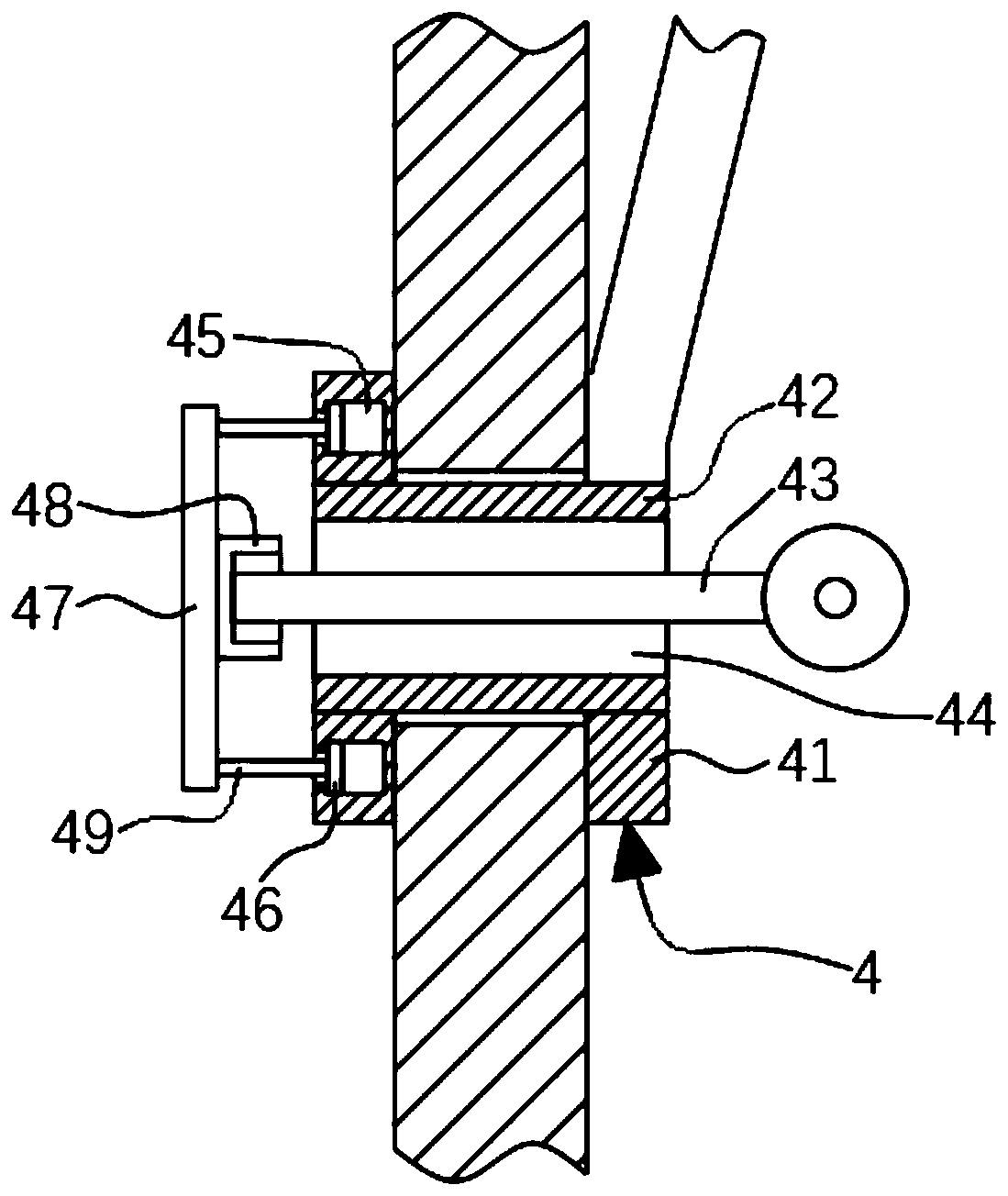

[0042] refer to Figure 4 , this embodiment is further set as follows on the basis of embodiment one:

[0043] The side of the cover 47 close to the ventilation hole 44 is fixedly connected with a sealing member 48. The sealing member 48 is composed of a central round block 482 and a protrusion 481. The inner surface of the ventilation hole 44 is axially provided with a plurality of protrusions to cooperate with the protrusion 481. 422 of the depression.

[0044] Preferably, both the depression 422 and the protrusion 481 adopt an arched structure,

[0045] By setting the recess 422 on the inner wall of the ventilation hole 44, the surface area of the ventilation hole 44 can be increased without increasing the linear distance of the inner wall of the ventilation hole 44, and the effect of thermal stress compensation can be played. The outer side has experienced thermal expansion and contraction for a long time, and the inner wall will inevitably be torn under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com