Fabricated shear wall structure provided with steel plate mesh wrapped with concrete and based on prefabricated steel structure

An outsourcing concrete, prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve problems such as danger, and achieve the effect of eliminating potential safety hazards, good seismic performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

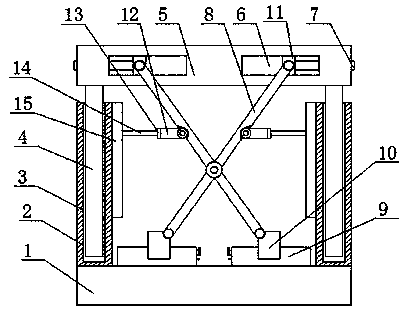

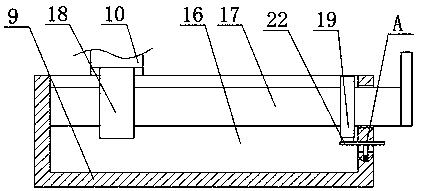

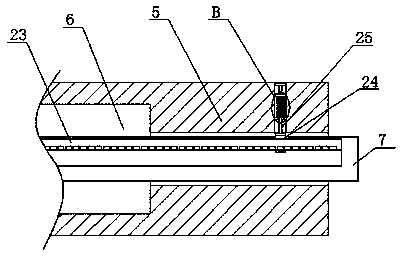

[0027] refer to Figure 1-7In this embodiment, a prefabricated steel structure-based prefabricated steel mesh-wrapped concrete shear wall structure is proposed, including a bottom beam 1, and the top of the bottom beam 1 is symmetrically fixed with two limit columns 2, and the top of the limit column 2 A limit slot 3 is opened, and a connecting column 4 is slidably connected in the limit slot 3, and the tops of the two connecting columns 4 respectively extend to the top of the limit column 2 and are fixedly installed with the same upper beam 5, one of the upper beams 5 There are two connecting grooves 6 in lateral symmetry, and a connecting plate 11 is slidably connected in the connecting groove 6, and one side of the connecting plate 11 is connected with a connecting shaft in rotation, and one end of the connecting shaft extends to the outside of the upper beam 5 and is fixedly installed with a supporting column 8. The top of the bottom beam 1 is symmetrically fixed with two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com