Automatic calibration method for engine knock

An automatic calibration and engine technology, applied in the direction of engine components, engine ignition, machine/engine, etc., to achieve the effect of simplifying the control logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

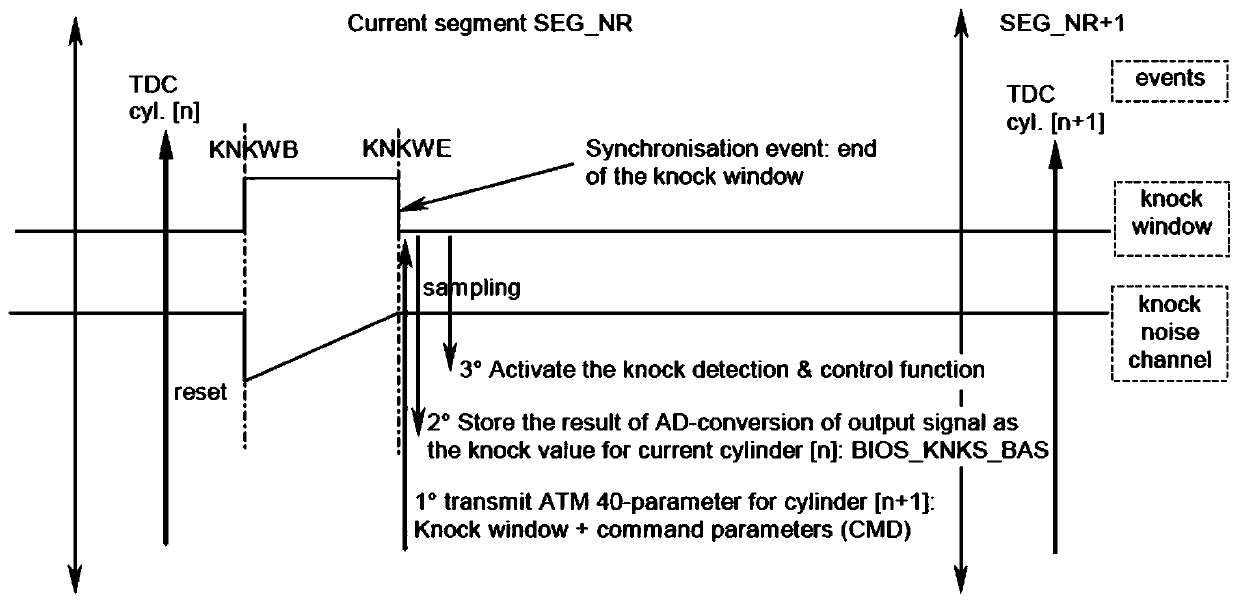

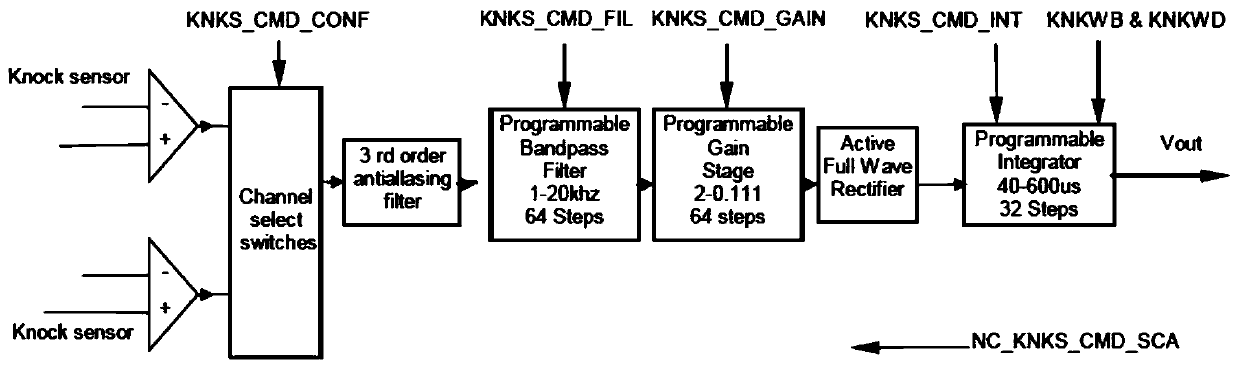

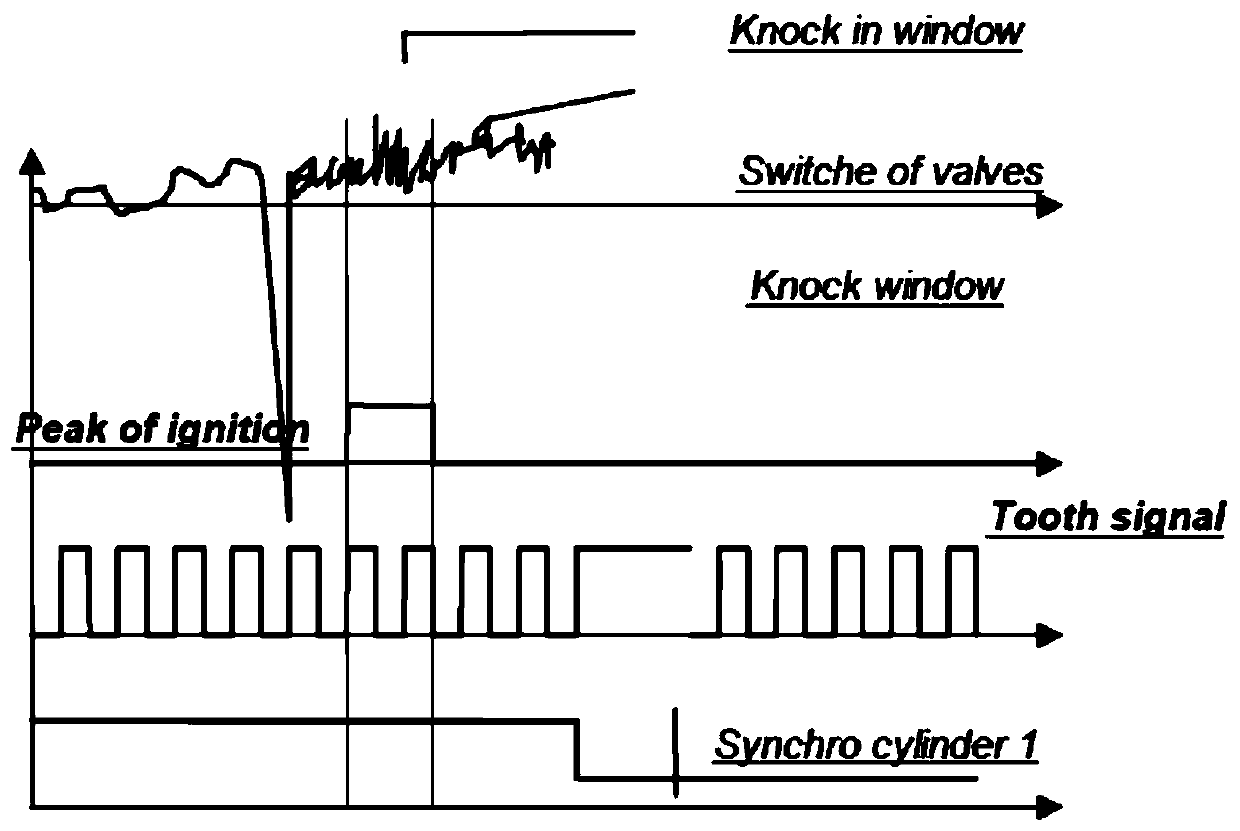

[0033] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

[0034] Artificial intelligence has been applied in various industrial fields. The present invention introduces the inventive technology of engine knock intelligent calibration, self-adaptation and self-learning, which is applied to the important link knock control matching in engine calibration, and has been verified effectively, greatly improving work efficiency and data validity and consistency ;In addition to being able to collect various data of equipment operation (such as temperature, speed, fuel consumption, ignition solution, etc.), and store the data for secondary analysis, intelligently optimize the calibration, through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com