Double-drive secondary magnetic pump

A magnetic pump and pumping pump technology, applied in the field of dual-drive secondary magnetic pumps, can solve the problems of magnetic pump power and eddy current heat limit can not meet the use requirements, to reduce manufacturing difficulty and production costs, convenient manufacturing, safe use Effect of Reliability Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

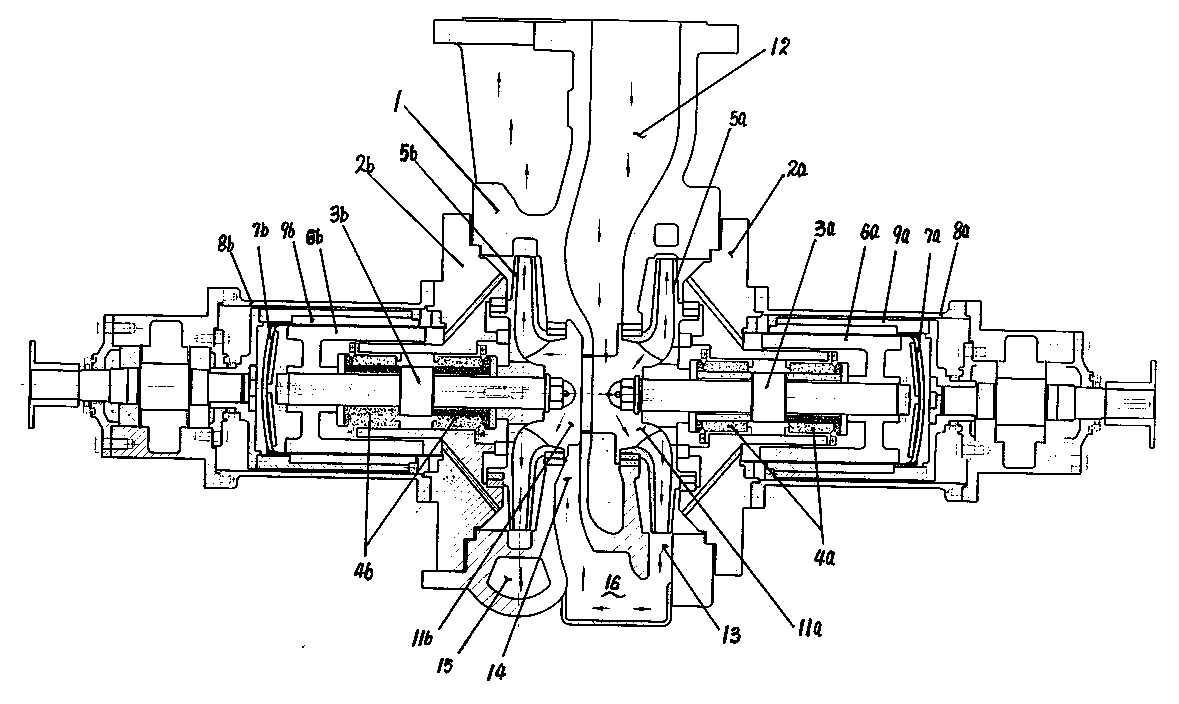

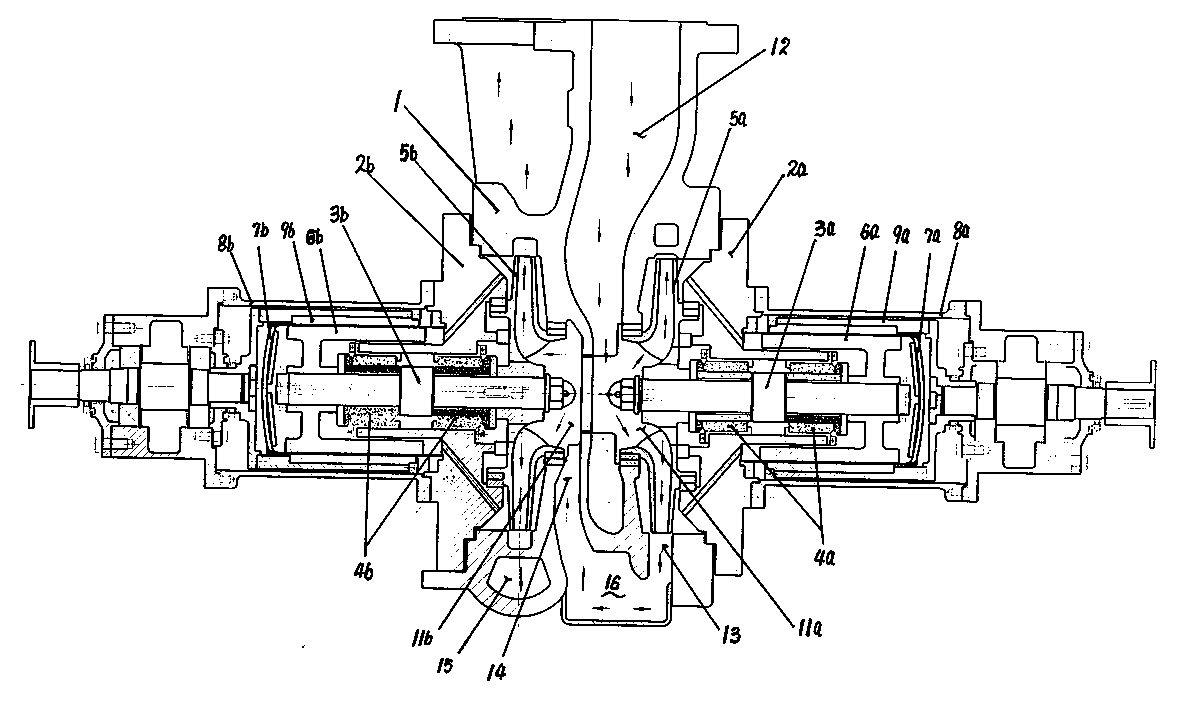

[0014] The dual-drive secondary magnetic pump of the present invention is composed of a primary pump A and a secondary magnetic pump B;

[0015] The first-stage pump force pump includes a pump body 1, a right pump cover 2a, a right pump shaft 3a, a right pump shaft sliding bearing device 4a, a right impeller 5a installed on the front end of the right pump shaft in the pump cavity, and a right impeller 5a installed on the rear end of the right pump shaft. The right inner magnetic rotor 6a on the top, the right spacer sleeve 7a that is sealed and fixedly connected with the right pump cover, the right drive shaft connecting frame 8a that is docked and fixedly connected with the right pump cover, and the right outer magnetic rotor that is fixedly installed on the shaft end of the right drive shaft 9a;

[0016] The two-stage pump force pump includes a pump body 1, a left pump cover 2b, a left pump shaft 3b, a left pump shaft sliding bearing device 4b, a left impeller 5b installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com