Adiabatic accelerating rate calorimeter with dynamic thermal inertia correction features

An accelerating calorimeter and adiabatic technology, applied in calorimeters, measuring heat, instruments, etc., can solve problems such as thermal analysis kinetic research and thermal risk safety assessment deviation, so as to improve kinetic parameters and improve reliability , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

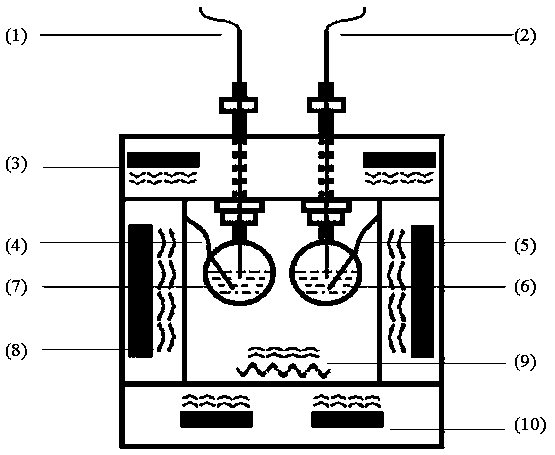

[0081] The adiabatic acceleration calorimeter with dynamic thermal inertia correction feature of the present invention has figure 1 The structure diagram shown is based on the construction of the instrument first, including the reference side test channel 4-1, the sample side test channel 4-2, the furnace body (furnace wall and furnace bottom) 4-3 and the shell 4-4 ,Such as Figure 4 Shown:

[0082] Taking into account the uniformity and stability of the temperature field of the entire adiabatic furnace after heating. First of all, based on the thermal conductivity, the higher the thermal conductivity, the better the thermal conductivity. The material of the furnace cover and furnace body is copper (387W / (m·K)) whose thermal conductivity is second only to metallic silver (412W / (m·K) K)), to improve the uniformity of the temperature field as much as possible. Then, the insulation cotton with better heat insulation effect is stuffed around the heat insulation furnace, and ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com