Valve storage test design method

A technology of test design and test method, applied in mechanical valve testing, mechanical component testing, machine/structural component testing, etc. It can solve the problems of difficult storage test and storage period evaluation, complex function and internal structure, and achieve optimization. Design, improve the effectiveness of evaluation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

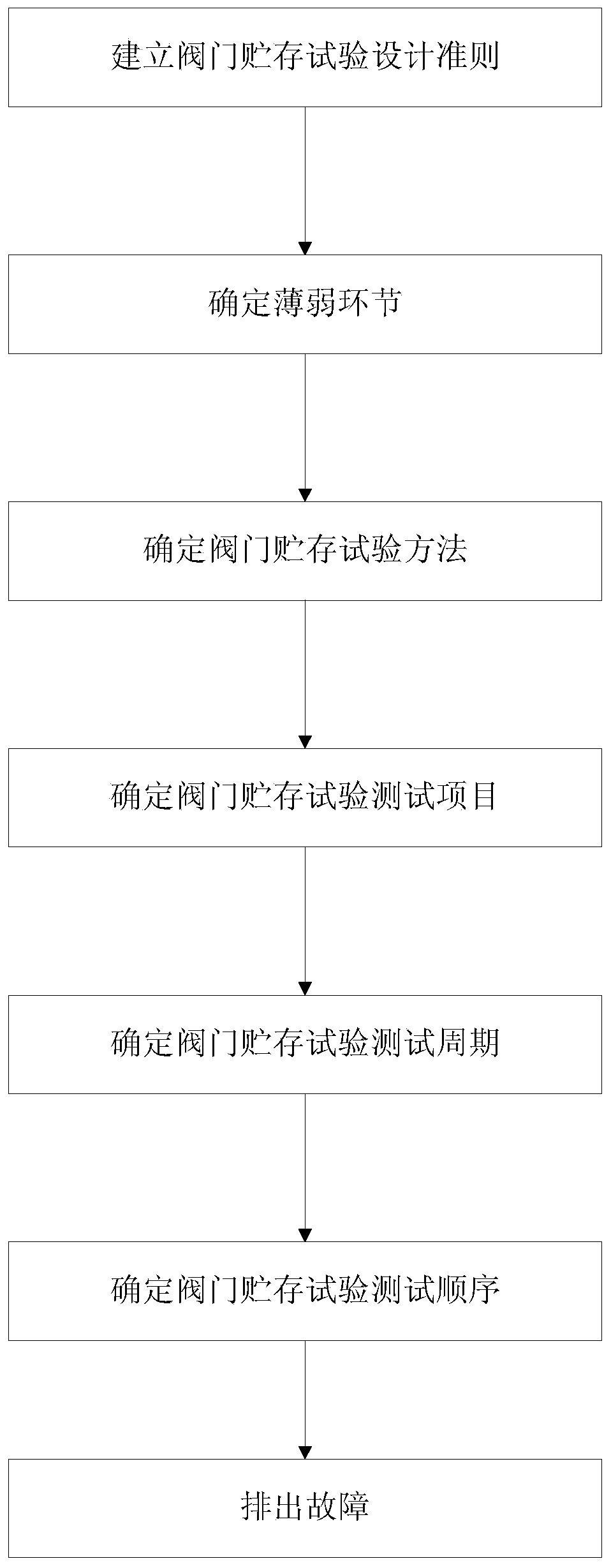

Method used

Image

Examples

Embodiment

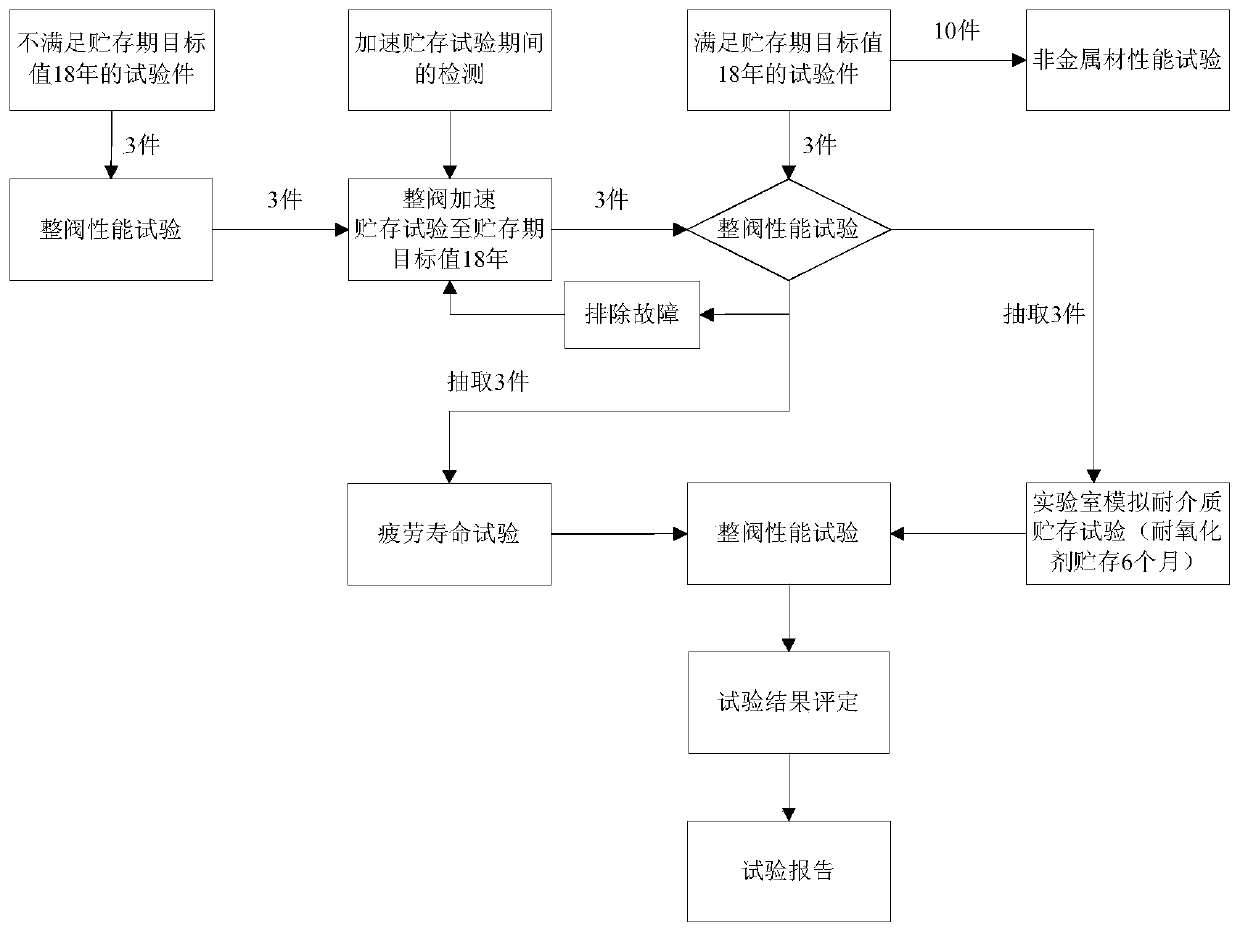

[0139] Taking the oxygen relief valve as an example, the storage test design method is as follows:

[0140] The oxygen safety relief valve needs to be activated during the flight. While ensuring airtightness, it also has the functional requirement of overpressure opening and exhausting. It needs to adapt to high and low temperature thermal environment, random vibration environment, and oxidant-resistant medium corrosion environment. The internal structure is complex, and the sensitive components are under pressure for a long time. The dynamic seals made of carboxynitroso fluororubber materials need to ensure that the dynamic seal performance is normal within 6 months of oxidant resistance storage. Therefore, the whole valve of the oxygen relief valve is taken as the weak link (test piece) at the whole valve level, and the carboxynitroso fluororubber seal is taken as the weak link (test piece) at the component level.

[0141] According to the existing information, it is estima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com