Comprehensive efficiency quantitative testing and calculation method for automotive electric energy system

A technology of comprehensive efficiency and calculation method, which is applied in the direction of vehicle testing, machine/structural component testing, and measurement of electrical variables. Vehicle electrical system and other issues, to achieve the effect of strong versatility and portability, easy test process, and perfect instantaneous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

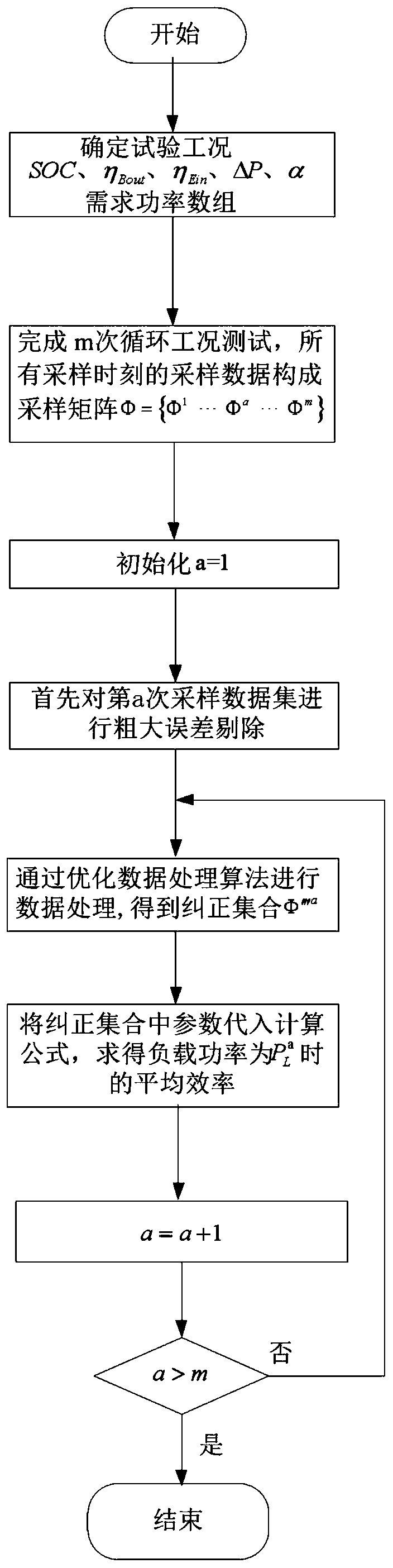

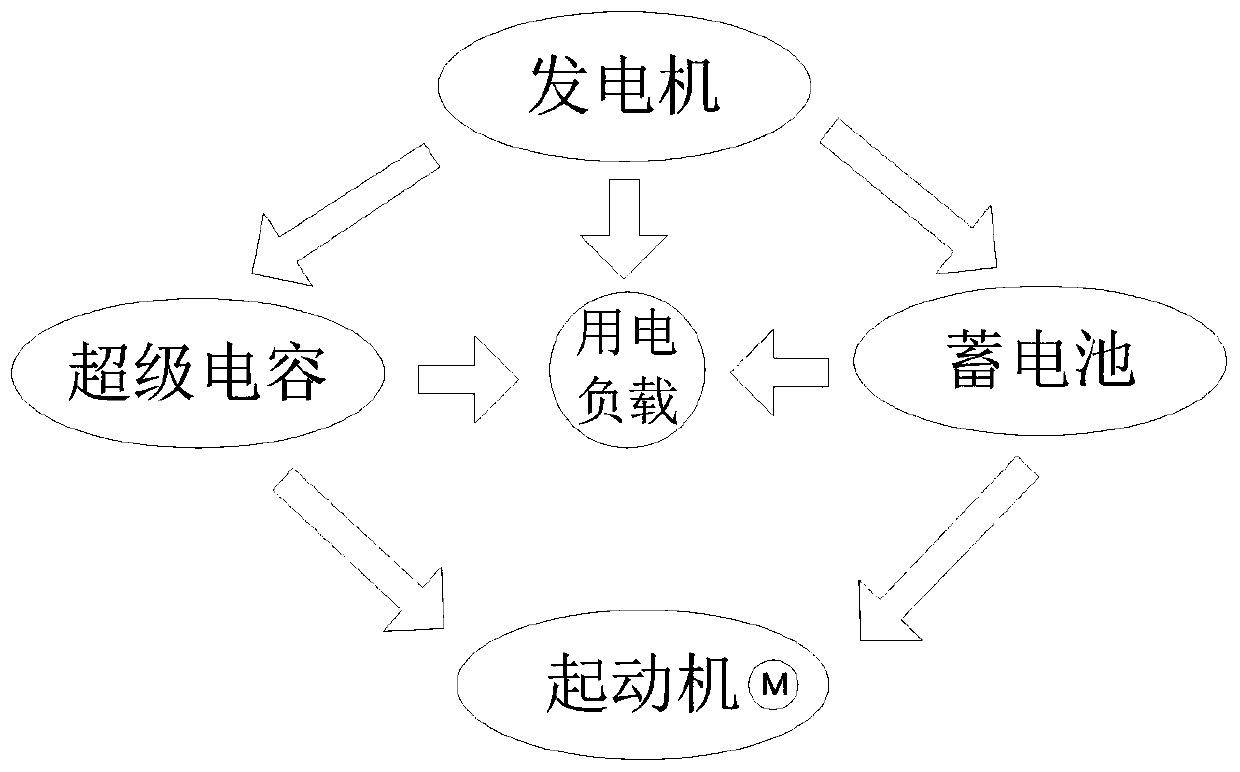

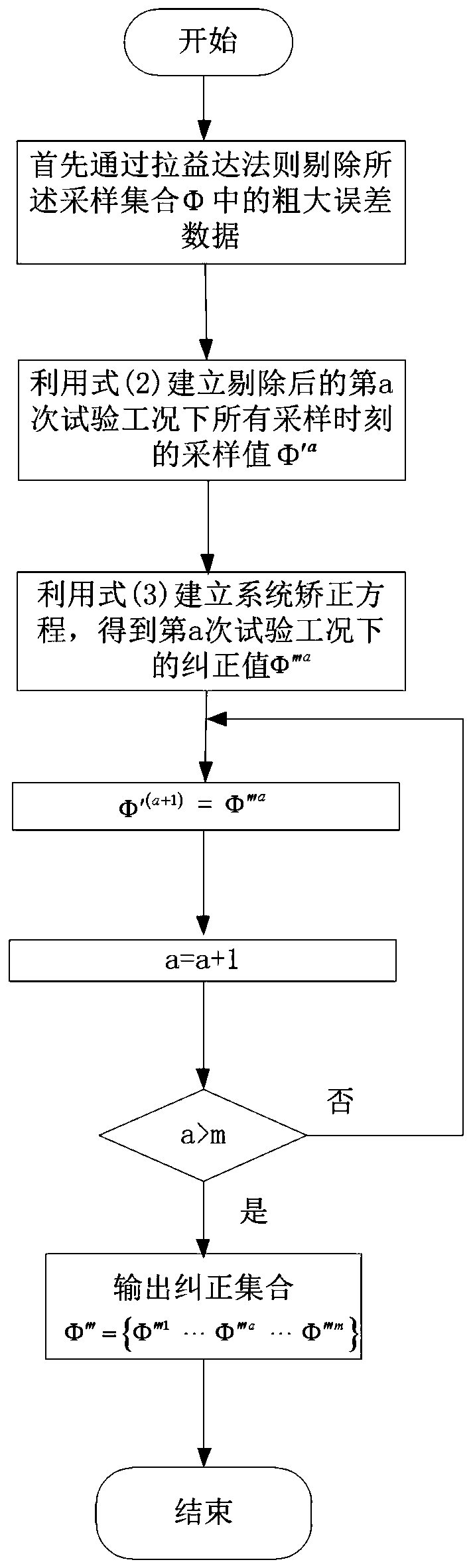

[0041] In this embodiment, a comprehensive efficiency quantitative test and calculation method for the automobile electric energy system is as follows: firstly determine the set of cycle working conditions, experimental constant parameters, number of tests, and load demand power in the vehicle environment; The load demand power in the cycle test is carried out, and the data at the sampling time of each test is recorded to obtain the total sampling set; a general formula for calculating the average efficiency of the vehicle composite power supply system is proposed; through the Raida criterion and the optimized data processing algorithm Data processing to obtain the test value set corrected by the test; Substituting the corrected test quantity into the average efficiency calculation formula of the vehicle composite power system for calculation, and obtaining the average efficiency of the composite power system. Specifically, the test process is as follows figure 1 shown, and pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com