Production line kpi monitoring method, device, electronic equipment and readable medium

A production line and production data technology, applied in the direction of electrical program control, comprehensive factory control, program control, etc., can solve problems such as poor accuracy, large amount of collected data, and inability to obtain production line KPI in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

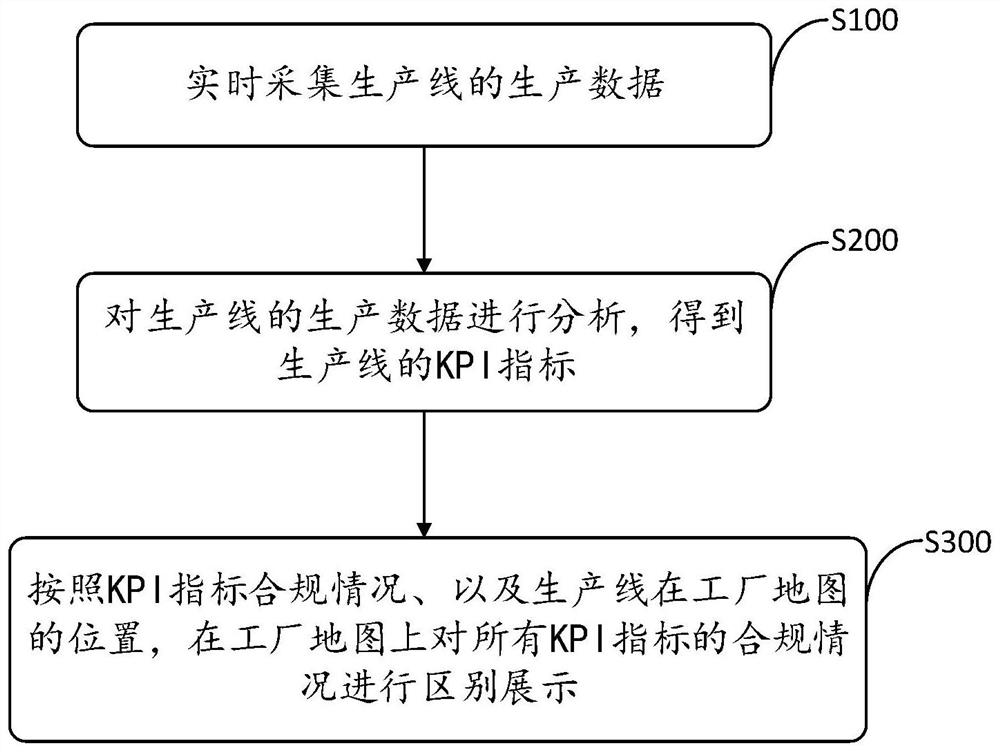

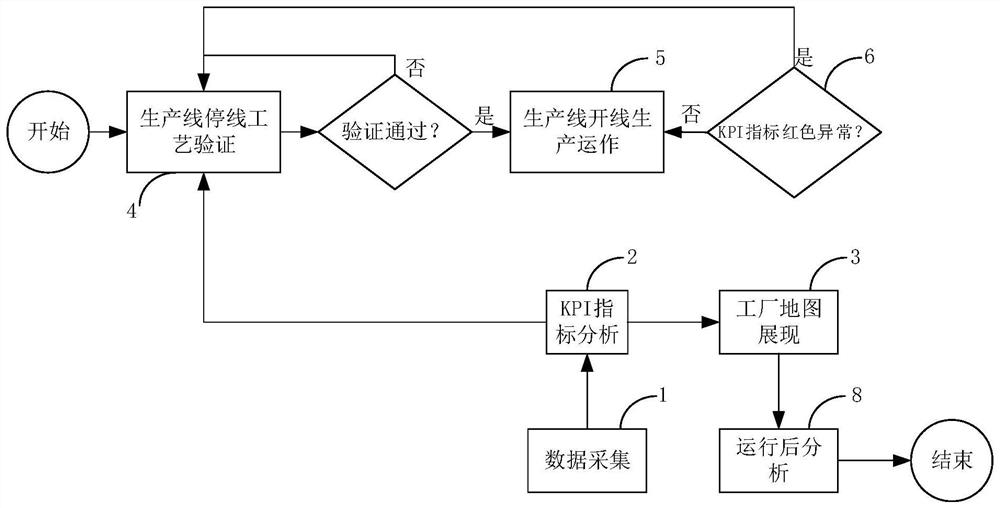

[0050] refer to figure 1 , a production line KPI monitoring method provided in this embodiment, taking PCBA manufacturing as an example, includes steps:

[0051] S100, collecting production data of the production line in real time;

[0052] Specifically, the PCBA production process includes sending out materials, basic baking, board supply, solder paste printing, spot fixing glue, printing visual inspection, high-speed machine placement, general-purpose machine placement, visual inspection before reflow, reflow soldering, furnace Post-comparison visual inspection, repair, plug-in, wave soldering, ICT / FT, repair, assembly / visual inspection, quality inspection, repair and storage, etc. The equipment required in the PCBA production process basically includes solder paste printing machines, placement machines, reflow soldering, AOI detectors, component trimming machines, wave soldering, tin furnaces, board washing machines, ICT test fixtures, and FCT test fixtures. Tools, aging ...

Embodiment 2

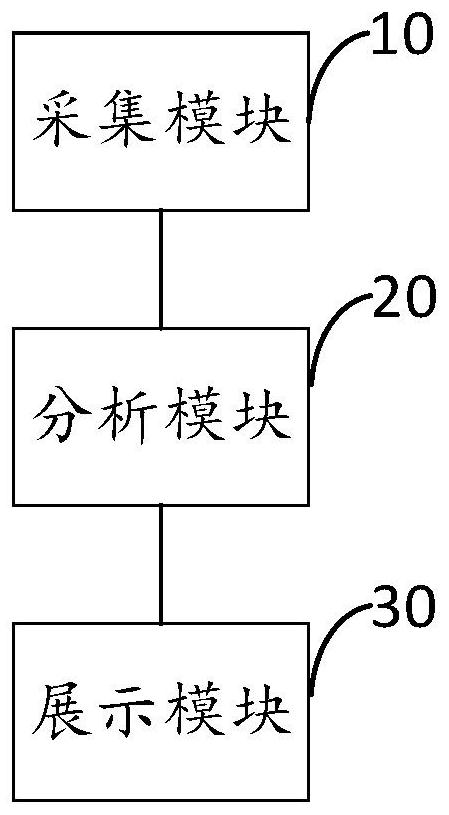

[0110] refer to image 3 , a production line KPI monitoring device provided in this embodiment, comprising a collection module 10, an analysis module 20 and a display module 30;

[0111] Acquisition module 10 is used for collecting the production data of production line in real time;

[0112] The analysis module 20 is used to analyze the production data of the production line to obtain the KPI index of the production line;

[0113] The display module 30 is used to differentiate and display the compliance status of the KPI indicators on the factory map according to the compliance status of the KPI indicators and the location of the production line on the factory map.

[0114] Further, the display module 30 includes a first display module, a second display module and a third display module;

[0115] The first display module is used to display the first color of the production line and the non-compliant KPI indicators on the factory map according to the position of the production...

Embodiment 3

[0124] refer to Figure 4 The embodiment of the present invention also provides an electronic device 40, including a bus 402, a communication interface 403, a memory 401, and a processor 400. The processor 400, the communication interface 403, and the memory 401 are connected through the bus 402; the memory 401 is used for storing A computer program that supports the processor 400 to execute the method in the first embodiment above, and the processor 400 is configured to execute the program stored in the memory 401 .

[0125] Further, an embodiment of the present invention also provides a computer-readable medium having a non-volatile program code executable by a processor, and the program code causes the processor to execute the method described in the first embodiment above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com