Rotatable overflow pipe cyclone separator and separation equipment

A technology of cyclone separator and overflow pipe, which is applied in the direction of swirl devices and devices whose axial direction can be reversed, can solve the problems of reduced air flow velocity, high pressure drop of cyclone separator, and high energy consumption, and achieve Promotes gas flow, suppresses short-circuit flow, and reduces pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

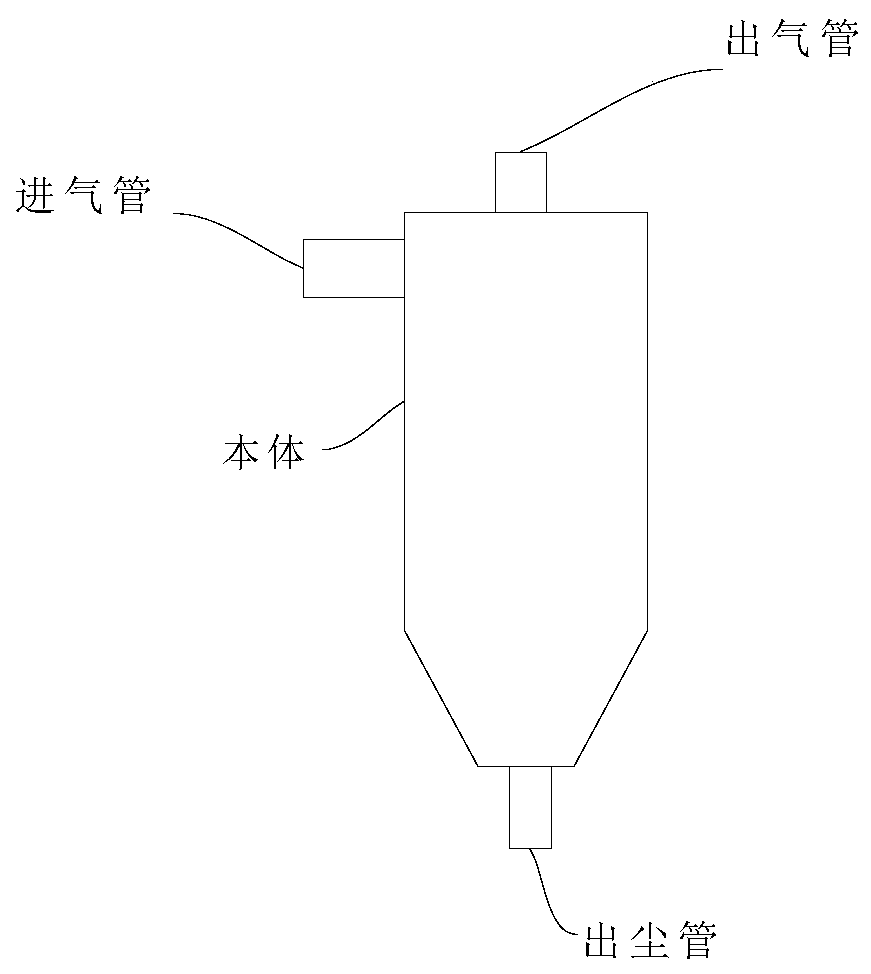

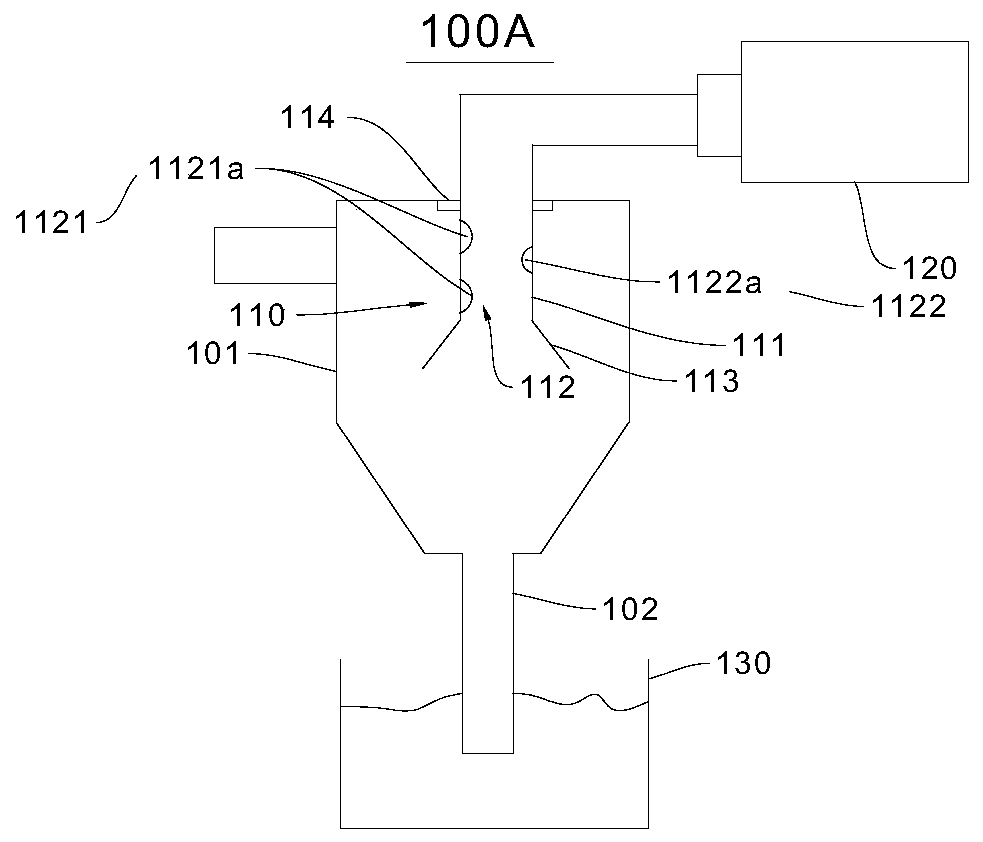

[0032] see figure 2 , this embodiment provides a rotatable overflow pipe cyclone separator 100A, which includes a separator body 101, the separator body 101 is the structure of a rotatable overflow pipe cyclone separator in the prior art, such as a conical cylinder body, the gas to be separated forms a swirling airflow inside the separator body 101 to achieve gas-solid or liquid-solid separation.

[0033] The upper part of the separator body 101 is provided with a gas inlet in the tangential direction of the cylinder, and the top of the separator body 101 is provided with a gas outlet. The separator body 101 includes a dust outlet pipe 102, and the dust outlet pipe 102 is arranged at the bottom of the separator body 101. And connected with the separator body 101.

[0034] It should be noted that the tangential direction involved in the present invention refers to the horizontal direction perpendicular to the axis centerline of the separator body 101. The gas inlet and gas ou...

Embodiment 2

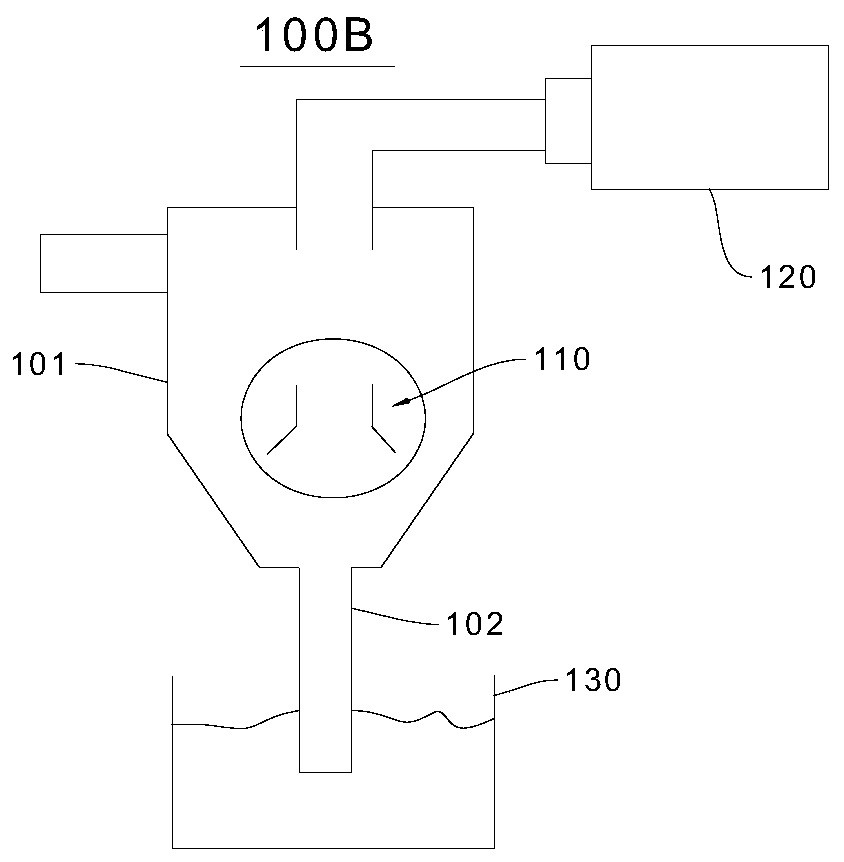

[0048] see image 3 The structure of the rotatable overflow pipe cyclone separator 100B provided in this embodiment is basically the same as that of the rotatable overflow pipe cyclone separator 100A provided in Embodiment 1, except that the location and structure of the flow suppression device 110 are added.

[0049] Specifically, the flow suppression device 110 is arranged in the middle of the separator body 101 and is connected to the separator body 101. Furthermore, the rotating tube 111 and the expansion piece 113 are both arranged in the middle of the separator body 101, and the rotating tube 111 can be opposite to the separator. The main body 101 rotates, and the extension piece 113 is connected with the separator main body 101 . It should be noted that since the flow suppressing device 110 is arranged in the middle of the separator body 101 in this embodiment, in order to ensure that the first rotating device 112 acts on the internally swirling gas, the rotating pipe 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap