Band saw grinding butting device

A docking device and band saw technology, which is applied in the tool manufacturing of sawing machine devices, metal sawing equipment, and other manufacturing equipment/tools, etc., can solve the problems of dull cutting edge, missing teeth, broken band saw, etc., and achieve processing efficiency. High performance, large processing capacity, simple and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

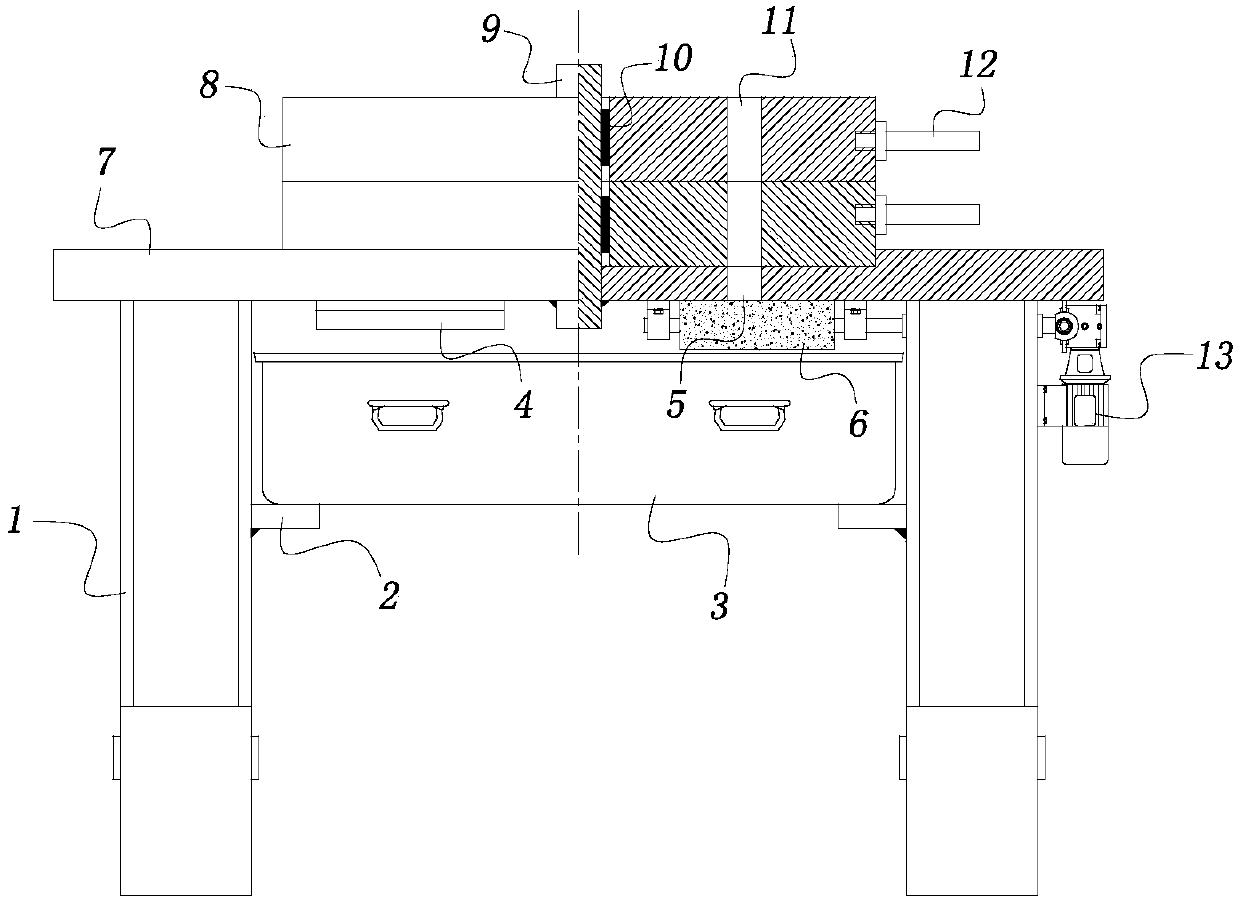

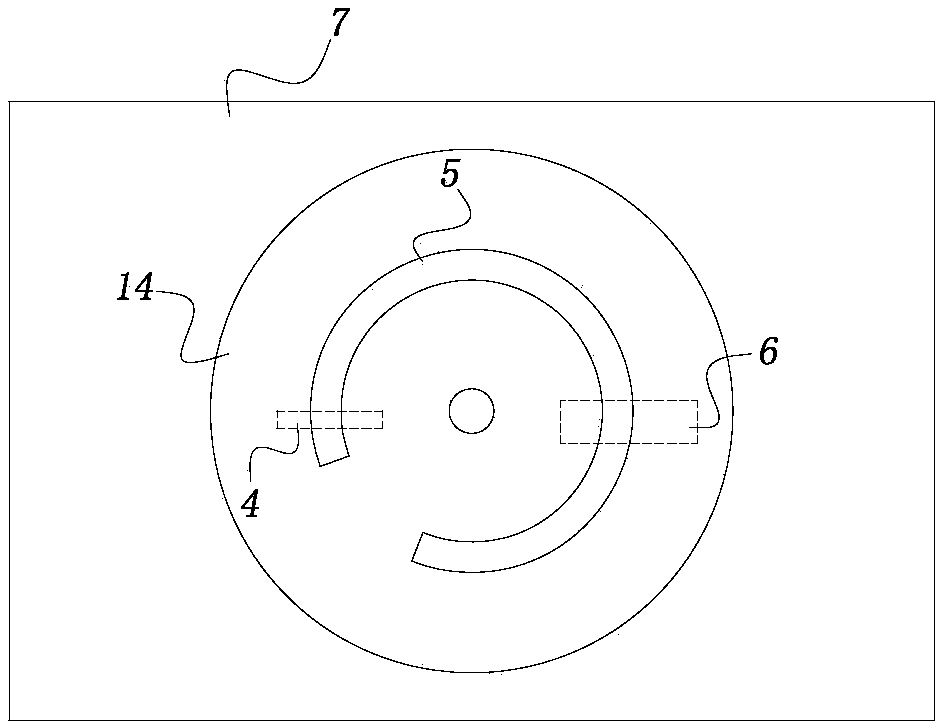

[0011] See Figure 1 to Figure 3 , the band saw grinding docking device of the present invention includes a bottom plate 7 supported by a support column 1 .

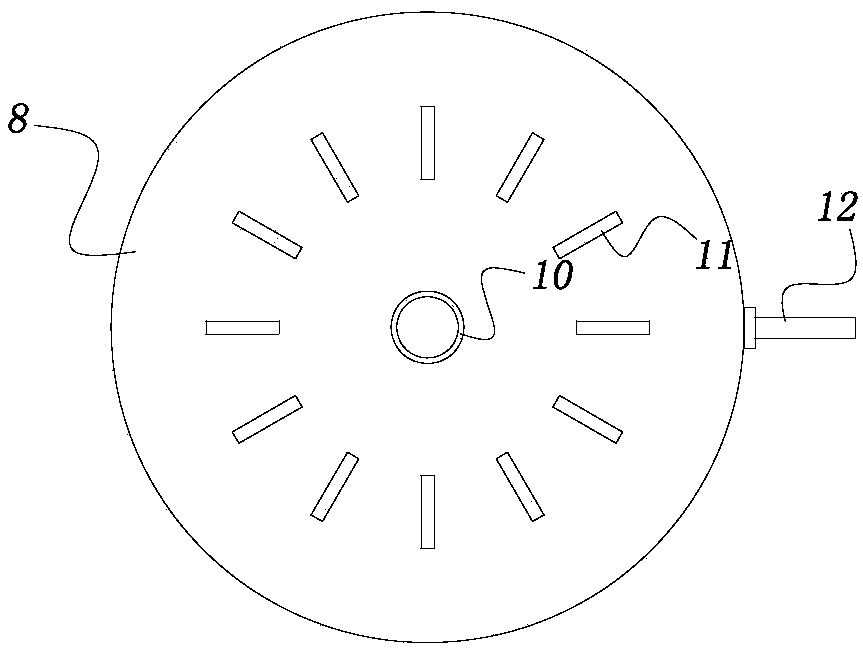

[0012] A vertical central rod 9 is fixedly connected to the middle part of the bottom plate 7, and two rotating disc bodies 8 are pierced on the central rod 9 from top to bottom. As shown in the figure, the rotating disk body 8 includes a flat cylindrical disk body, and a shaft hole is opened in the center of the disk body. Above, a plurality of band saw blade insertion holes 11 at equiangular intervals in the circumferential direction are opened in the middle of the disc body, and a hand lever 12 is fixedly connected to the outer edge of the disc body. The relative rotation between the two rotating disks 8 is realized by turning the hand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com