Patents

Literature

31results about How to "Large amount of single processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for removing organic solvent residual in raw medicine

InactiveCN101406765AAvoid destructionAvoid secondary pollutionSolvent extractionOrganic solventSorbent

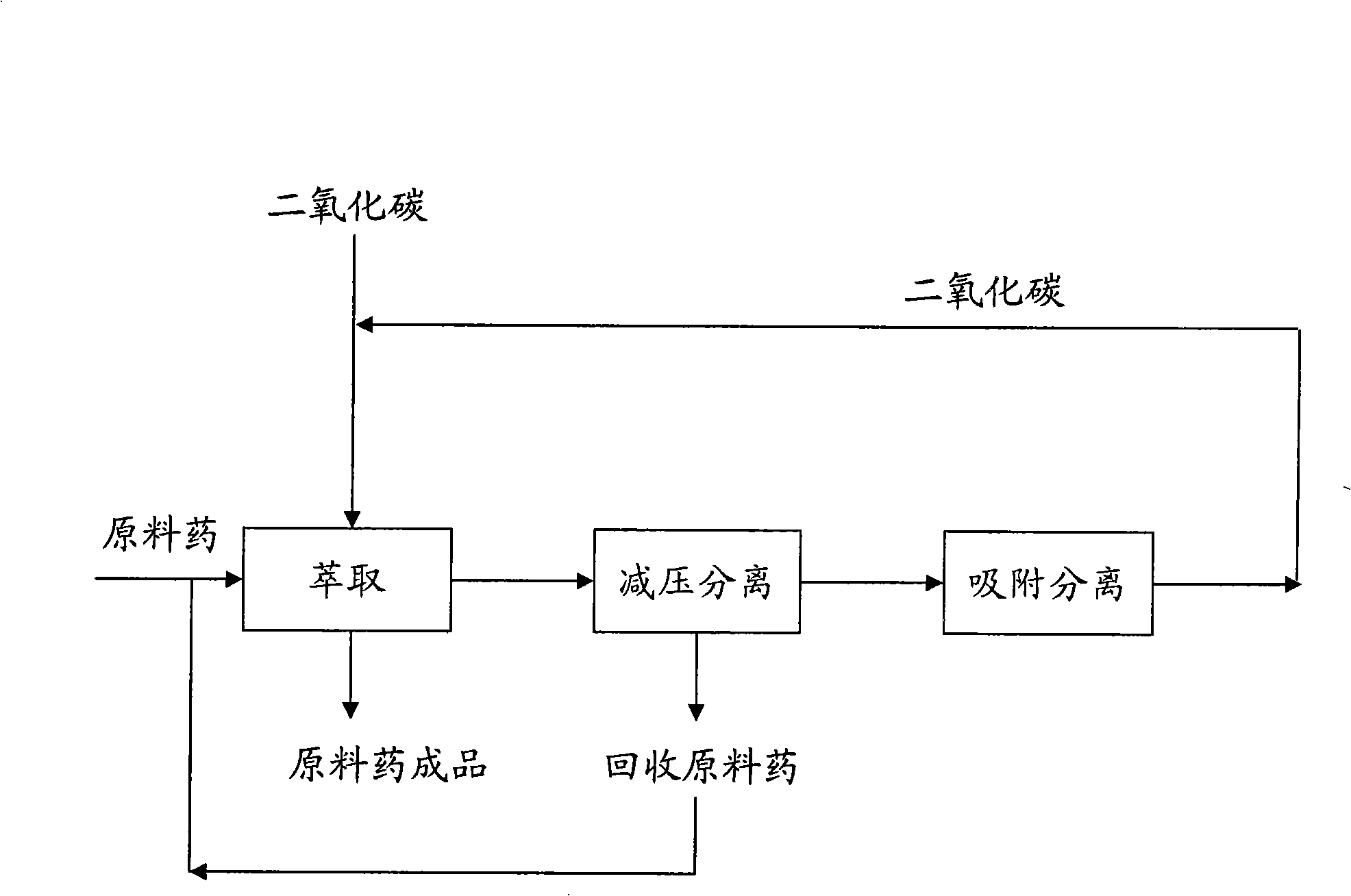

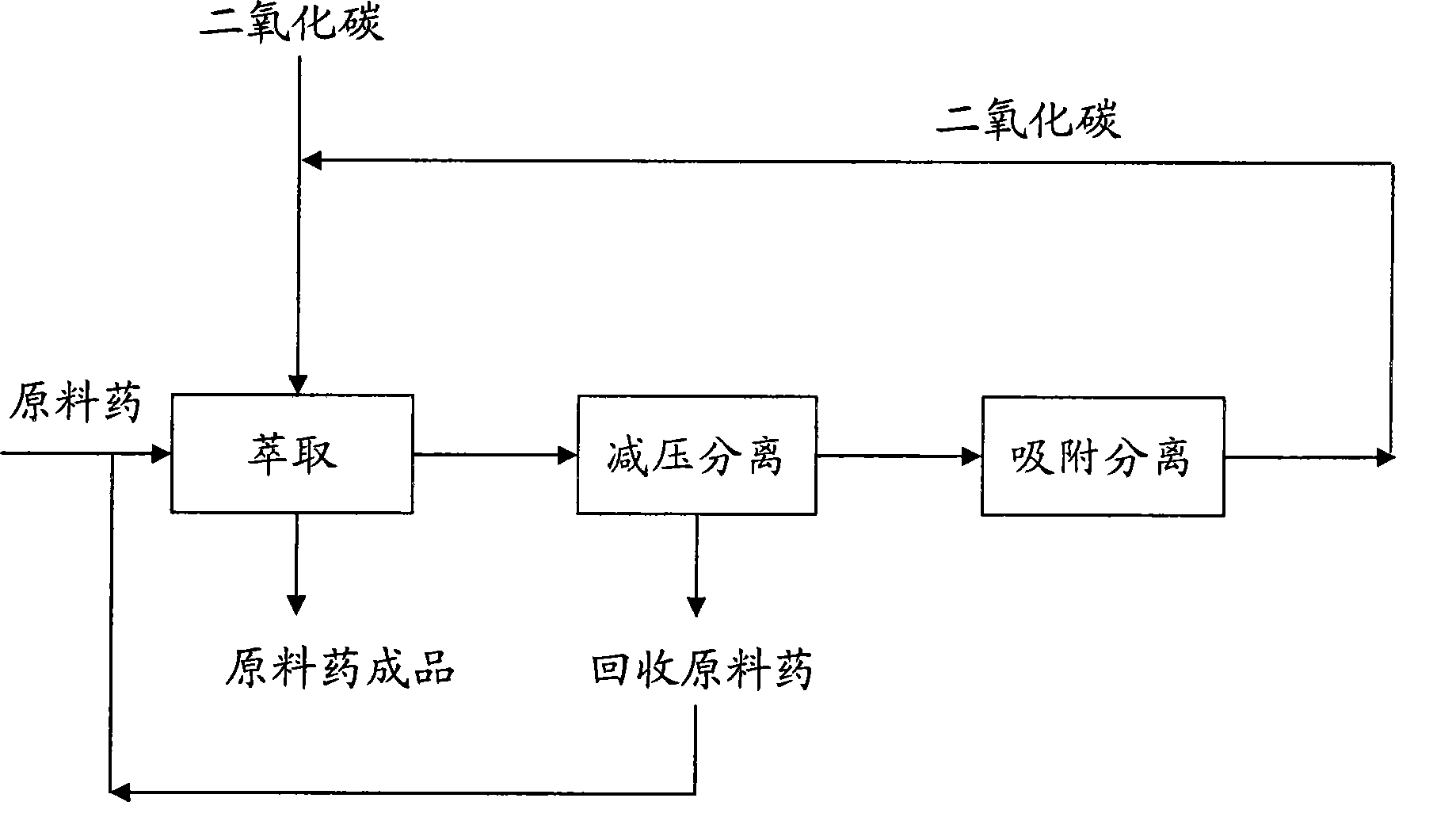

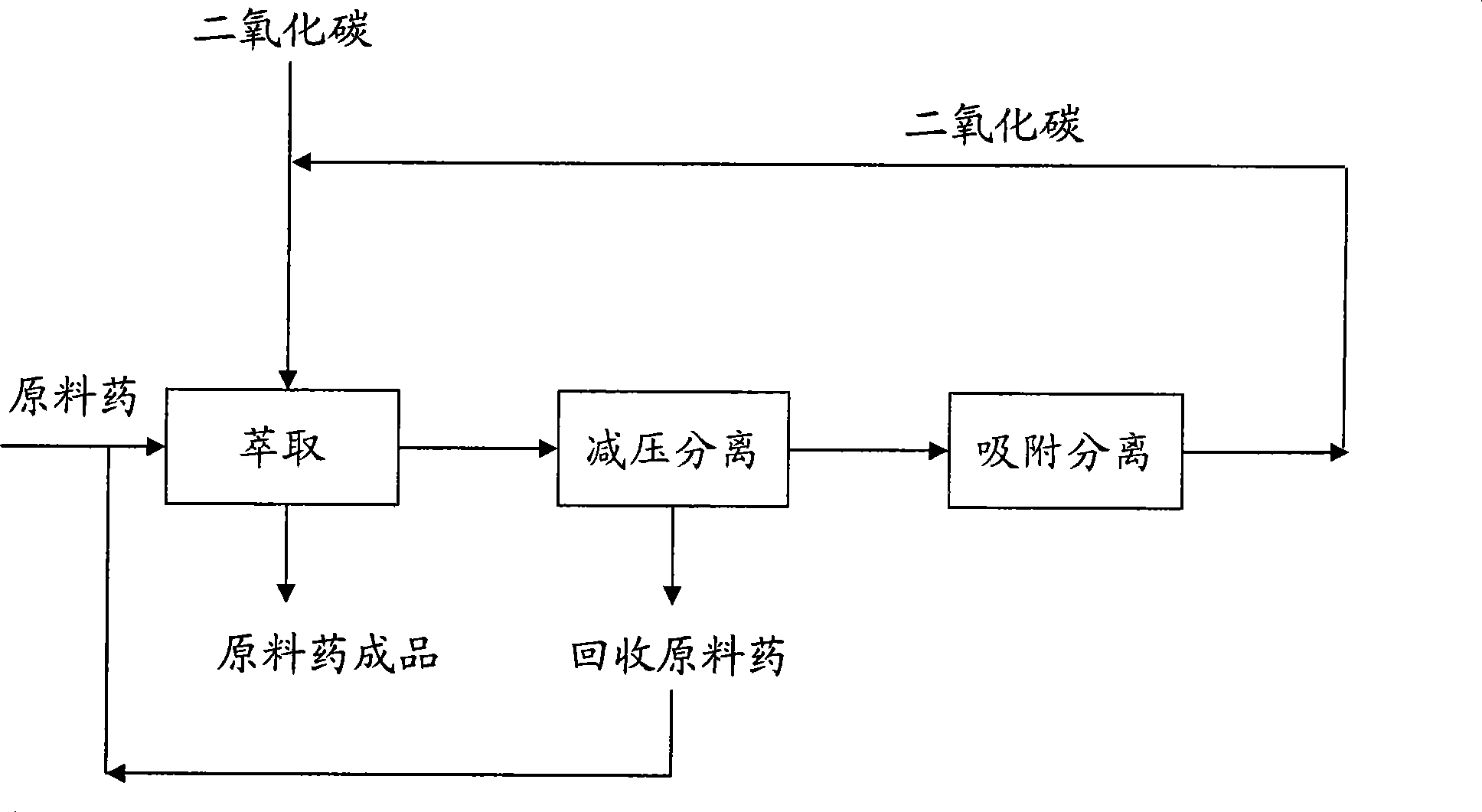

The invention discloses a method for removing residual organic solvents from a bulk drug, which comprises the following steps: firstly, extracting the bulk drug for 0.5 to 2 hours statically and then extracting the bulk drug for 0.5 to 6 hours dynamically under the condition that the temperature is between 35 and 80 DEG C and the pressure is between 10 and 40 MPa, so as to obtain a bulk drug finished product of which the residual organic solvent accords with the limit standard in an extraction kettle; secondly, decompressing and separating carbon dioxide flowing out of the extraction kettle under the condition that the pressure is between 4 and 7 MPa and the temperature is between 25 and 45 DEG C, collecting depositions in a separating kettle, and reclaiming the bulk drug in the depositions for reuse in the extraction kettle. The carbon dioxide flowing out of the separating kettle is adsorbed and separated by using an adsorbent, and the obtained carbon dioxide is introduced to the extraction kettle for recycling. The residual organic solvent in the bulk drug finished product obtained by the method accords with the limit standard, the yield of the bulk drug is high, and the carbon dioxide can be recycled. The method has the advantages of simple process, stable operation, economy and high efficiency, and suitability for industrial application.

Owner:ZHEJIANG UNIV

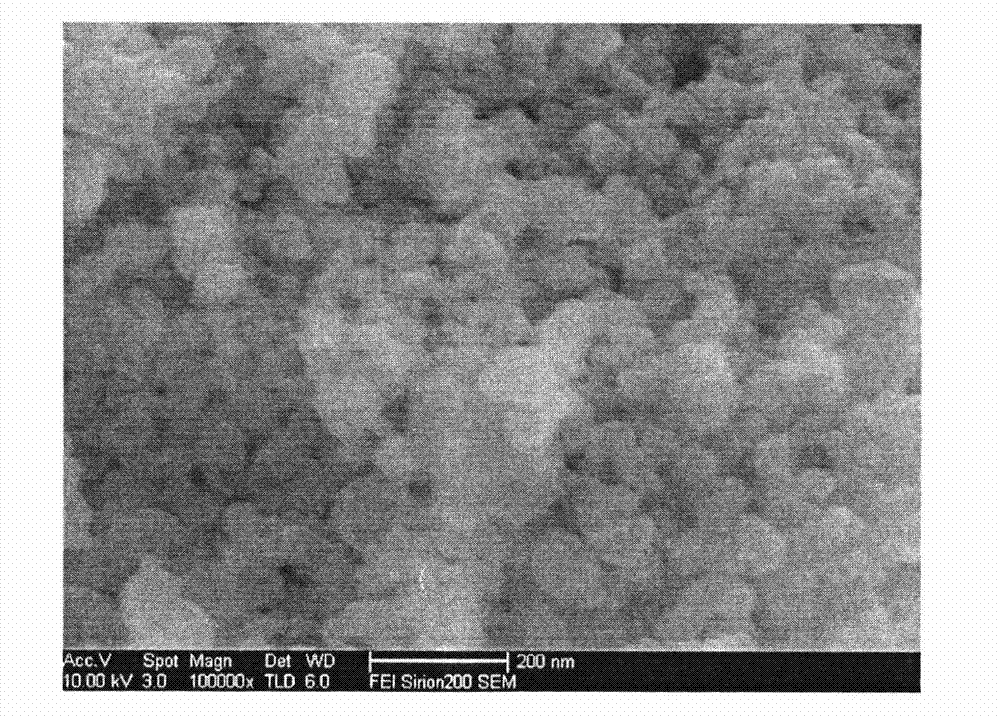

Preparation method of hydrophobic modified diamond abrasive

ActiveCN110713820ASolve reunionReduce consumptionOther chemical processesPerchloric acidCarboxylic group

The invention discloses a preparation method of a hydrophobic modified diamond abrasive. The method comprises the following steps: carrying out mixed acid treatment on a diamond raw material by sulfuric acid, nitric acid and perchloric acid according to a certain ratio, so that the surface of the diamond raw material has more -COOH groups; washing a diamond grinding material with water until the pH value of the supernatant is 5-7 by adopting a natural sedimentation or centrifugation method, and drying to obtain an agglomeration-free loose diamond grinding material; adding diamond powder to betreated into a high-speed mixer, spraying a hydrolyzed silane coupling agent, reacting carboxyl on the surface of diamond with the silane coupling agent at 80 DEG C for 3-5 minutes, and drying residual moisture to obtain the hydrophobic diamond powder. According to the preparation method, the mixed acid treatment is adopted so that the surface of the diamond is provided with more -COOH groups, andthe reaction capacity of the surface of the diamond and the silane coupling agent is improved; the method has the advantages of large single treatment capacity, short reaction time, simple operationprocess, low solvent consumption, energy saving and environmental protection.

Owner:HENAN UNION ABRASIVES

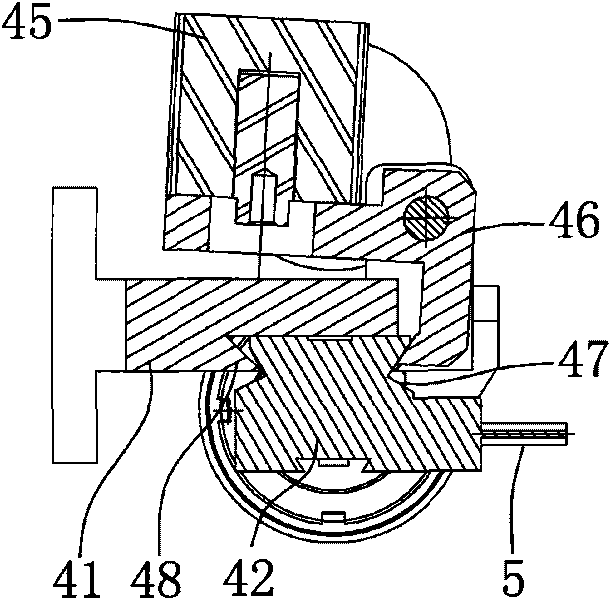

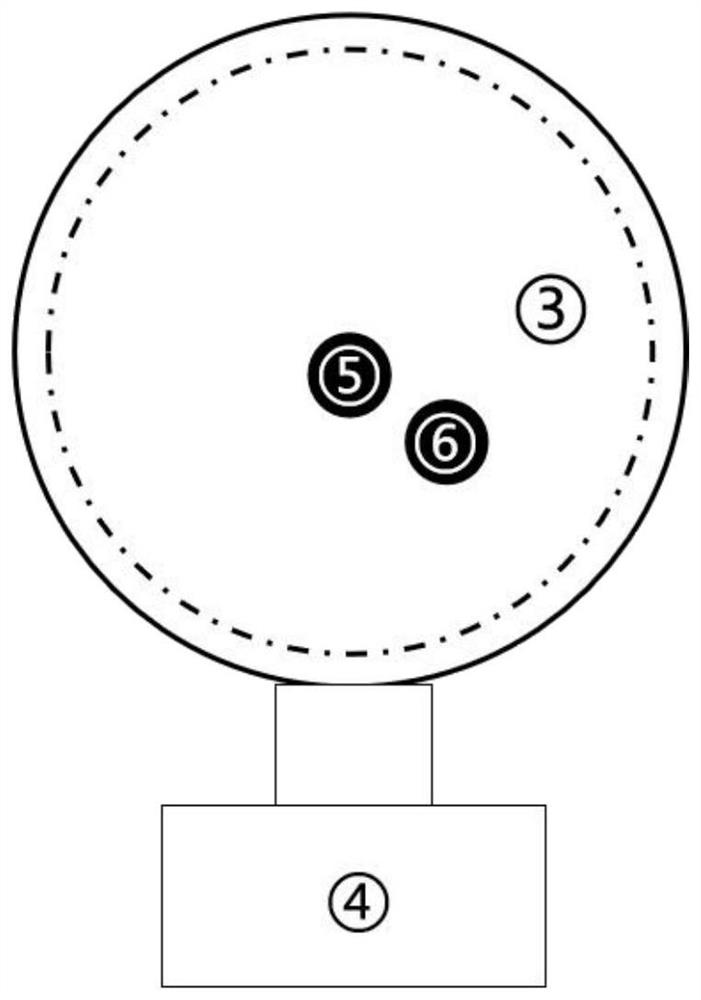

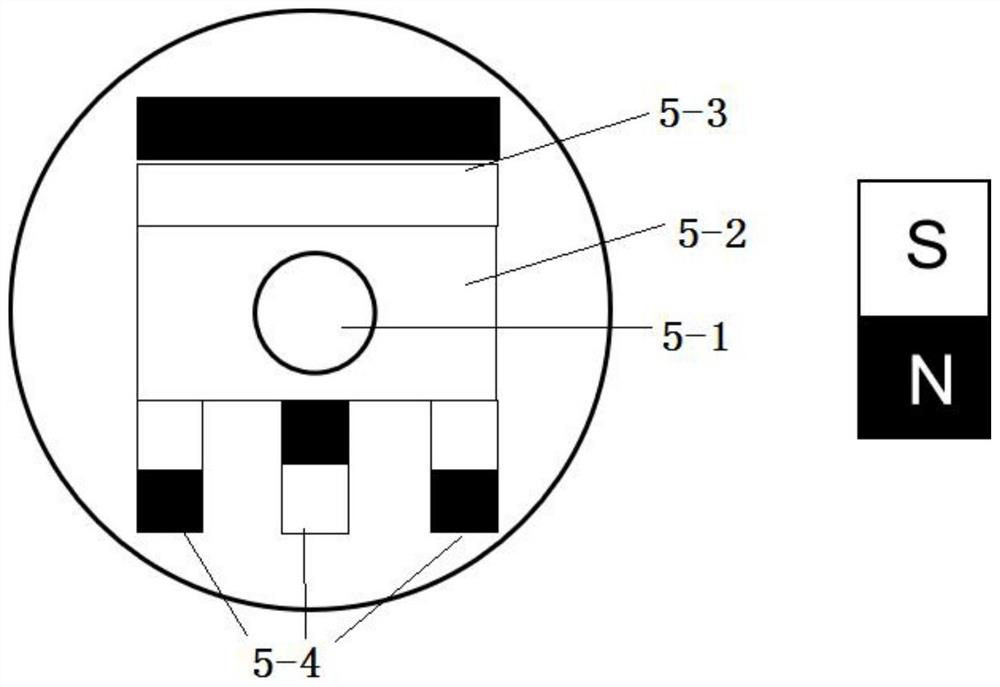

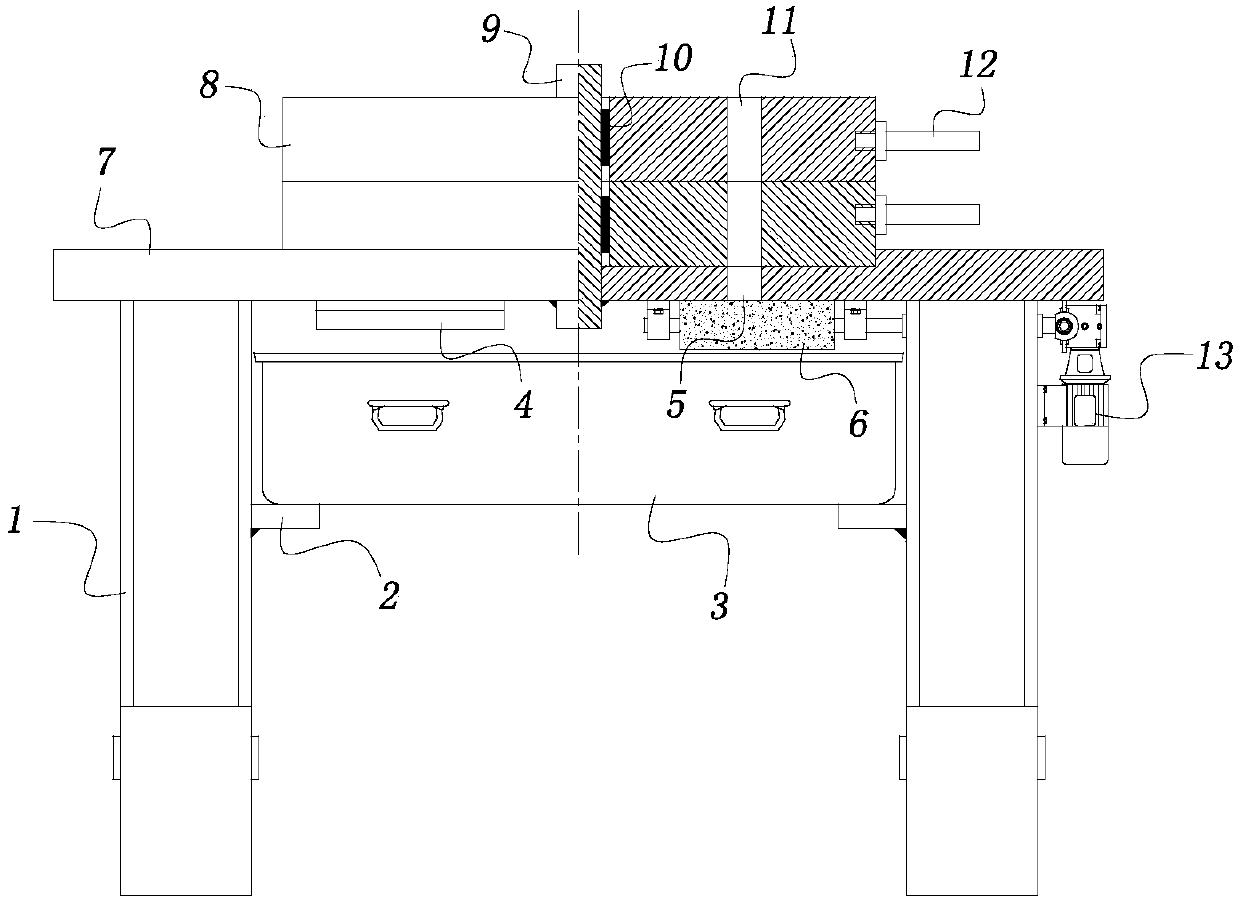

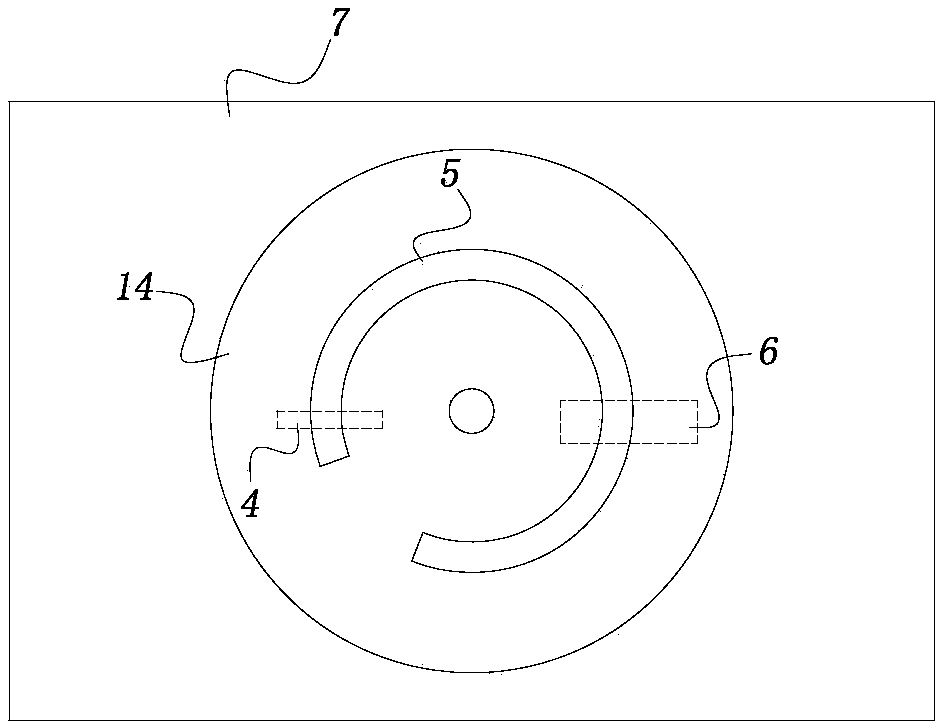

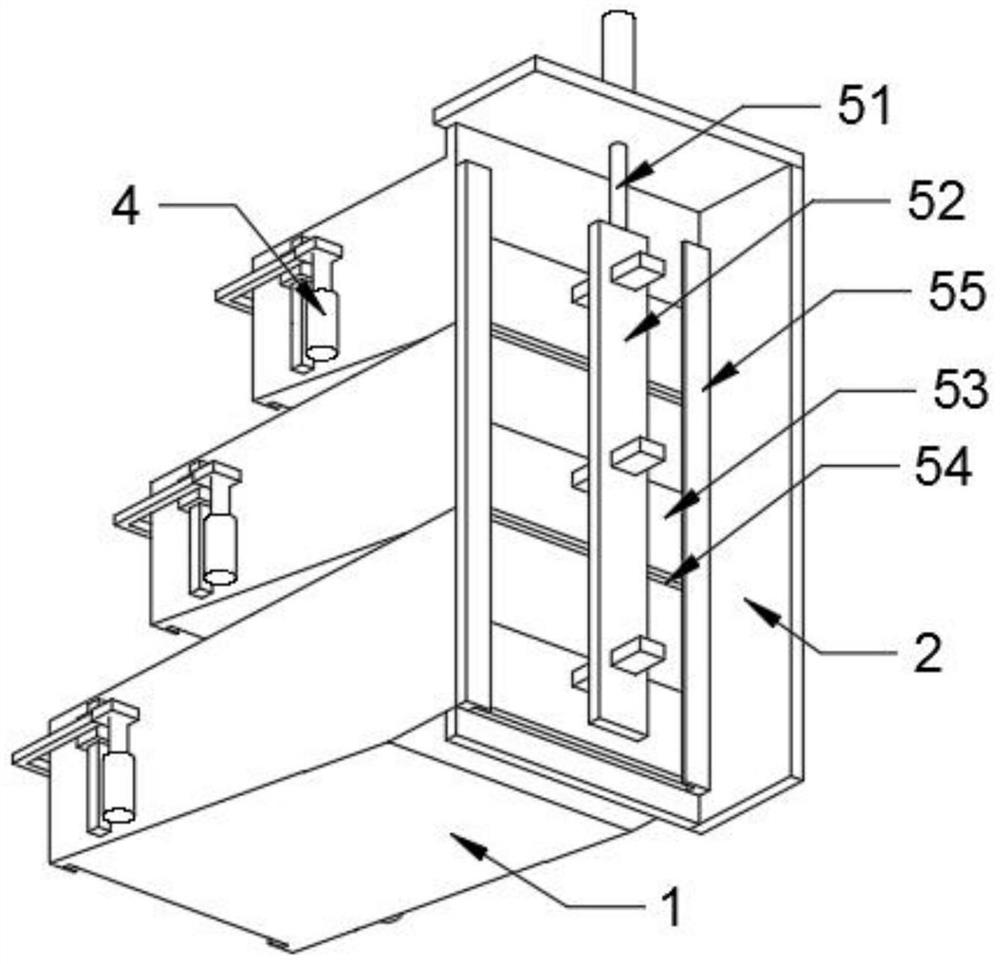

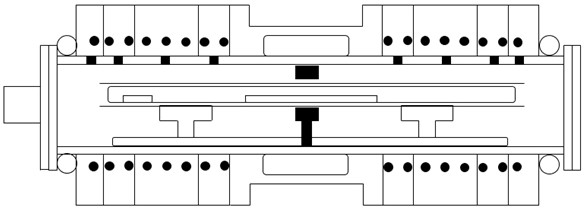

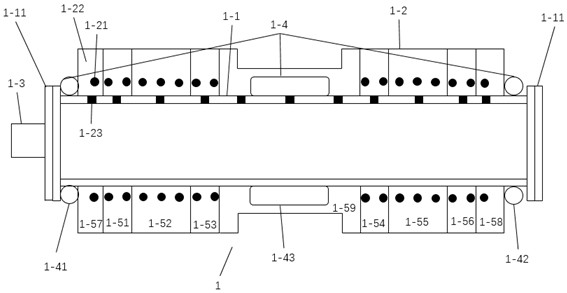

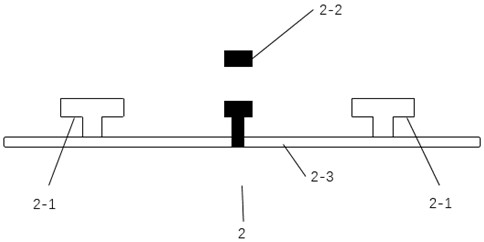

Grinding head mechanism for numerical control water drill grinding machine

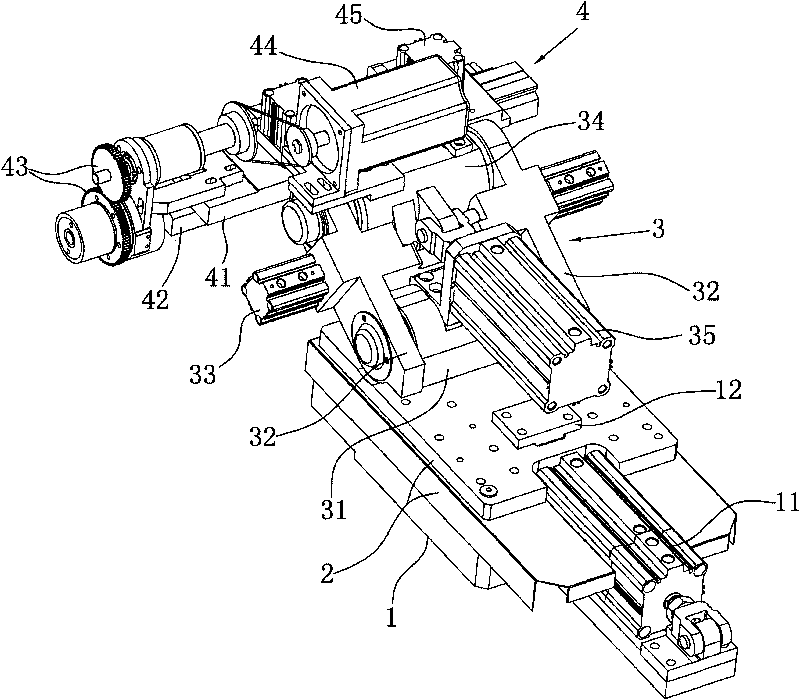

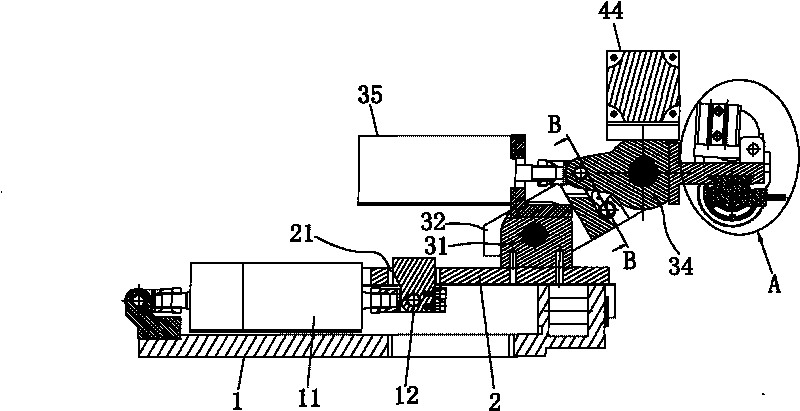

InactiveCN101722452ALarge amount of single processingLarge amount of processingEdge grinding machinesGrinding work supportsNumerical controlButt joint

The invention discloses a grinding head mechanism for a numerical control water drill grinding machine, comprising a bottom plate used for connecting with a grinding machine frame, and a horizontal advancing mechanism is arranged on the bottom plate, wherein one end of a connecting mechanism is hinged on the horizontal advancing mechanism, while the other end of the connecting mechanism is hinged with a clamp head; a screw rod is penetrated in the clamp head, and one end part of the screw rod is connected with an indexing motor arranged on the connecting mechanism through a transmission assembly; a plurality of clamp needles are axially arrayed in the clamp head along the screw rod in parallel; and the clamp needles are vertically engaged on the screw rod. The clamp needles are adjusted by the combination of the screw rod and the indexing motor so as to realize the grinding of a plurality of ridge surfaces of a water drill, thus the machining amount of a single time is large, and the efficiency is high. The indexing motor controls the rotating angle of the clamp needles and has high precision and good finished product quality. The arrangements of the horizontal advancing mechanism and the connecting mechanism can realize working procedures of automatic material taking and automatic butt joint so as to improve the degree of automation of equipment.

Owner:平湖思杰腾汽车设备制造有限公司

Separation and purification method for cell culture mixture

InactiveCN102191226AHigh purityStrong targetingImmunoglobulins against animals/humansMicroorganism based processesPurification methodsPore diameter

The invention discloses a separation and purification method for a cell culture mixture, comprising the step of: filtering the cell culture mixture by a filter, wherein the filter is provided with at least two layers of filtering membranes, the nominal pore diameter of each layer of filtering membrane is gradually reduced in the direction of flow of the filtrate, i.e. the nominal pore diameter of the first layer of filtering membrane is about 2-10mu m, and the nominal pore diameter of the final layer of filtering membrane is about 0.1-0.2mu m. The separation and purification method for a cell culture mixture disclosed by the invention has the advantages of strong pertinence, large treatment capacity, simple separation and purification step, stable product quality, low cost and the like.

Owner:BEIJING SKYWING TECH CO LTD

Method for manufacturing graphene nanoplatelets by arranging rotary screw rod in vibrating mill and graphene nanoplatelets

The invention provides a method for manufacturing graphene nanoplatelets by arranging a rotary screw rod in a vibrating mill and the graphene nanoplatelet. A graphene raw material and dry ice are added into a milling barrel of the vertical vibrating mill with the screw rod, and the graphene raw material can be cut into the graphene nanoplatelet with complete crystal lattices under the synergistic effect of vibration of the vibrating mill, shearing of the screw rod, and gas. Due to the fact that no grinding medium exists in the vibrating mill, the situation that the crystalline structure of graphite is damaged due to repeated grinding on the graphite is avoided, and the graphene nanoplatelet with the complete crystal lattices can be obtained. Meanwhile, the preparation process is simple, the processing capacity each time is high, and the graphene nanoplatelet can be prepared efficiently.

Owner:广西鑫锋电源科技有限公司

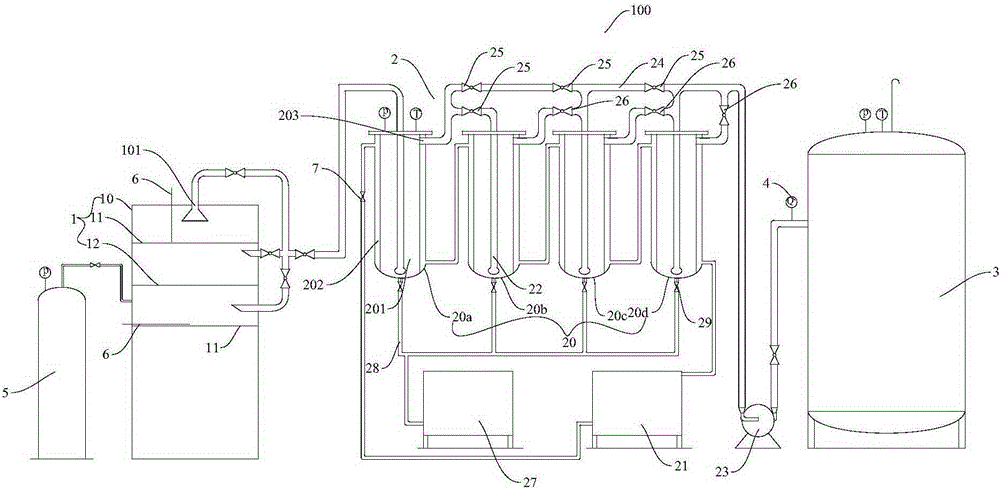

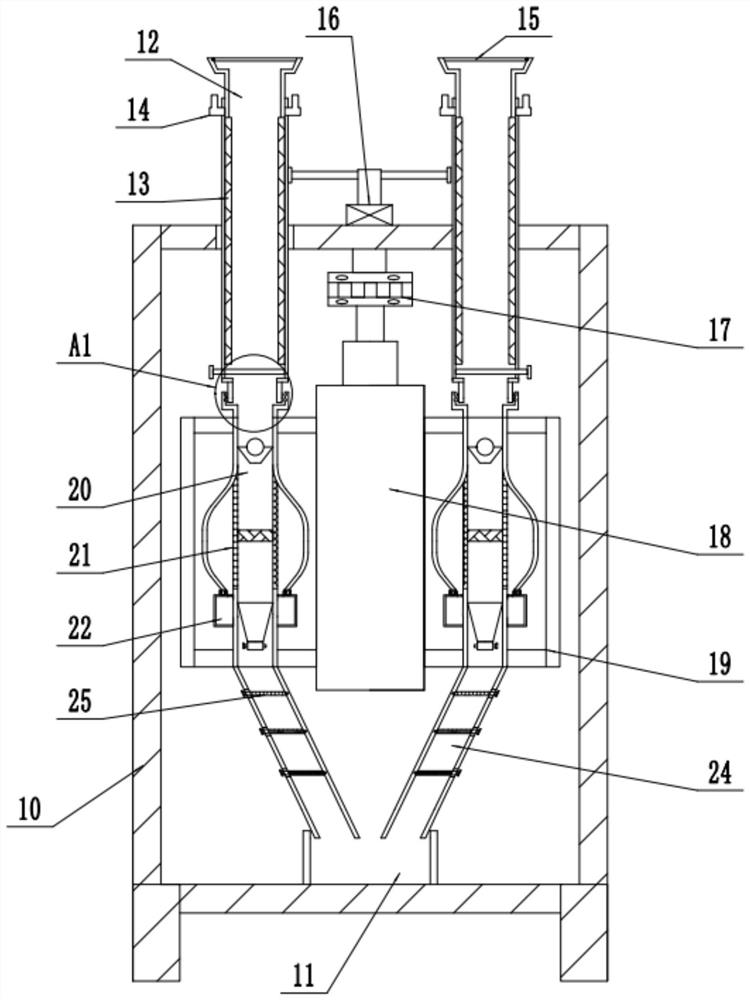

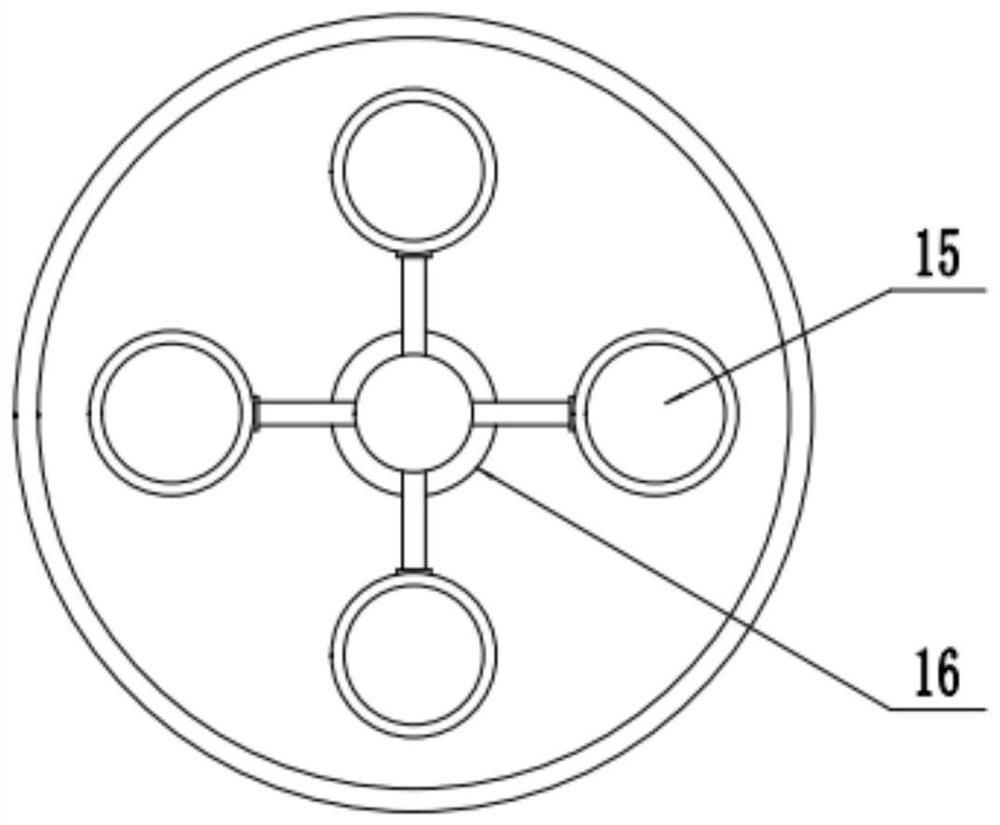

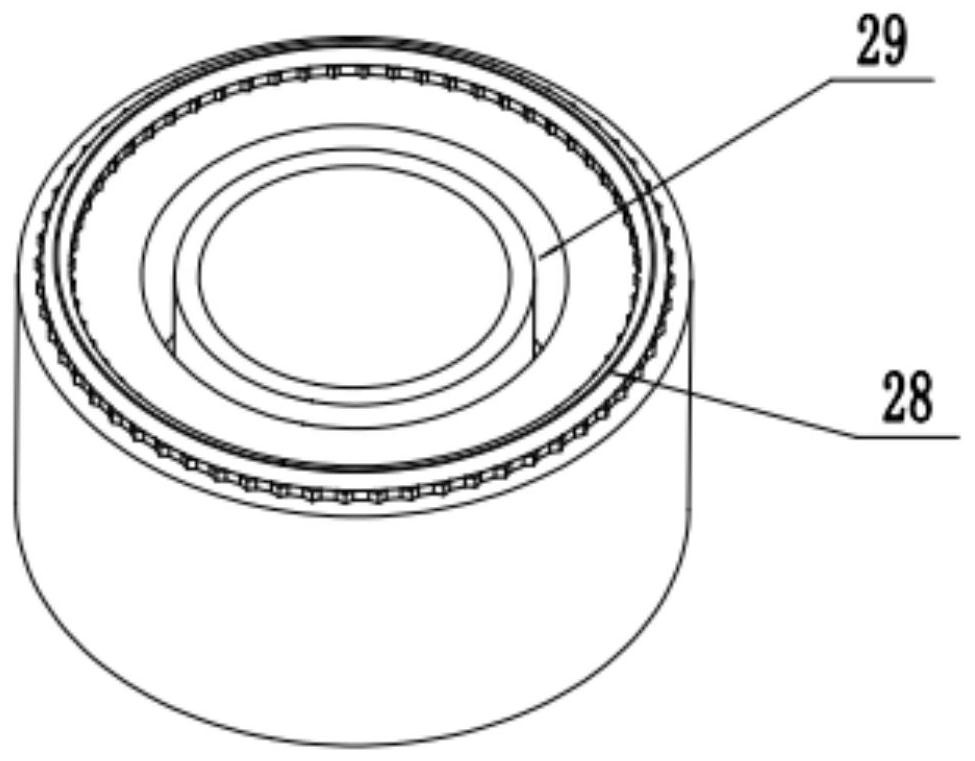

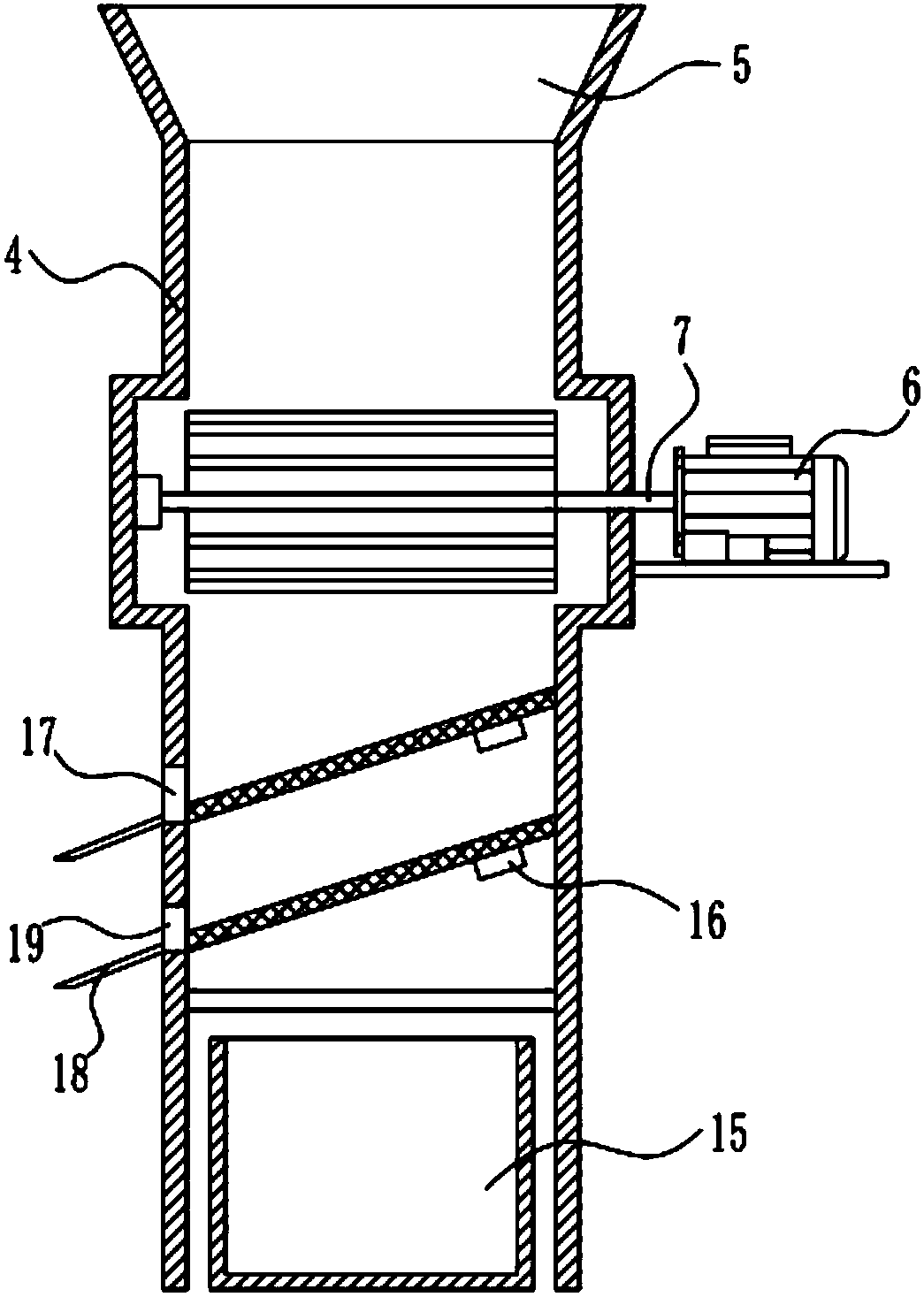

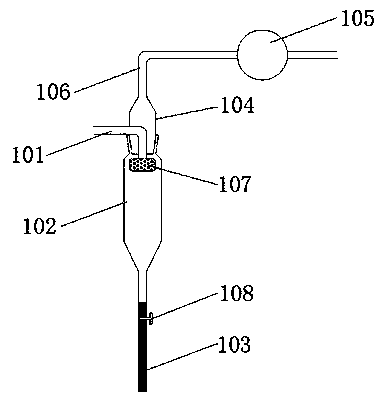

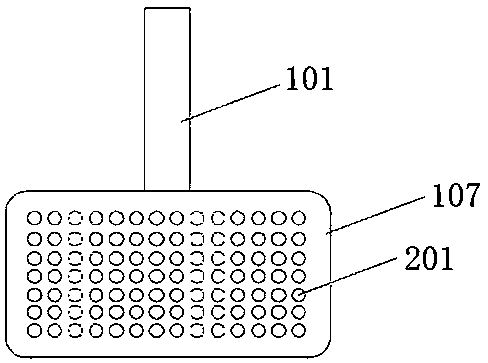

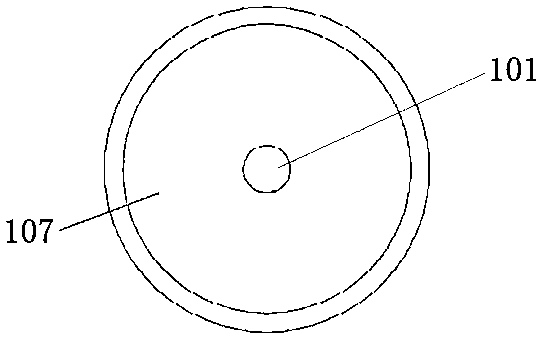

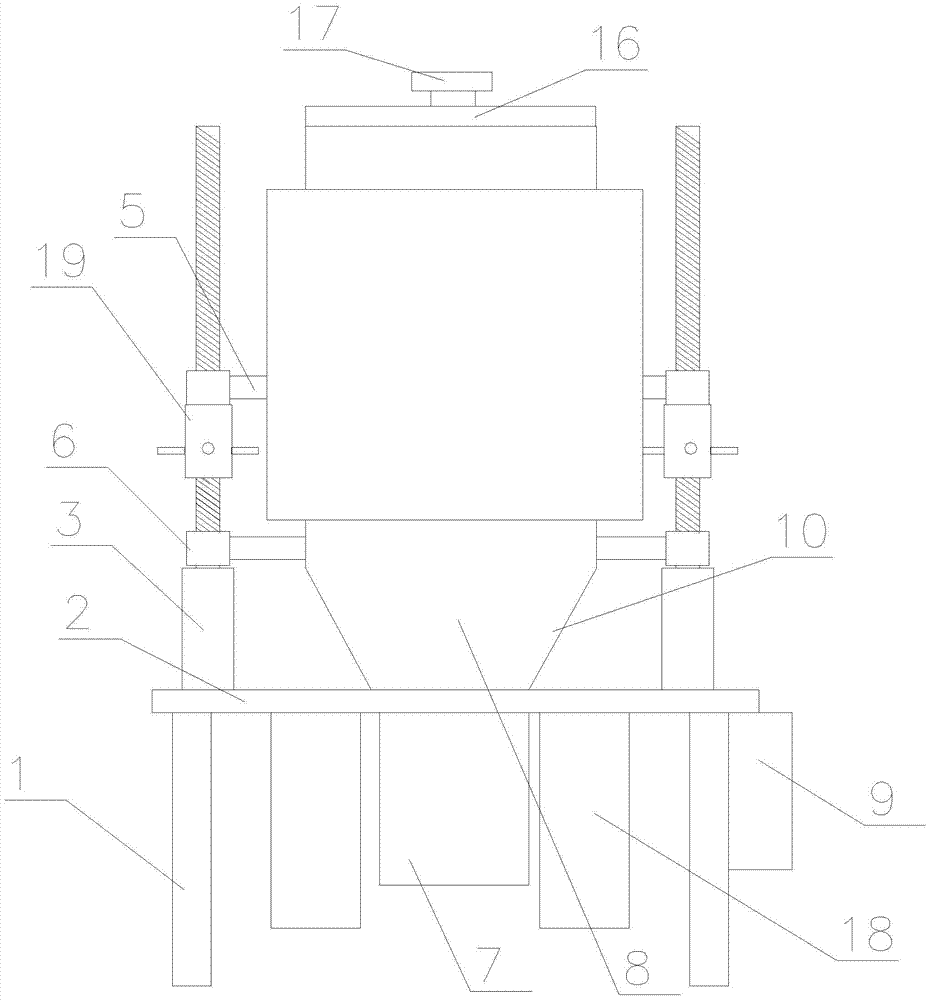

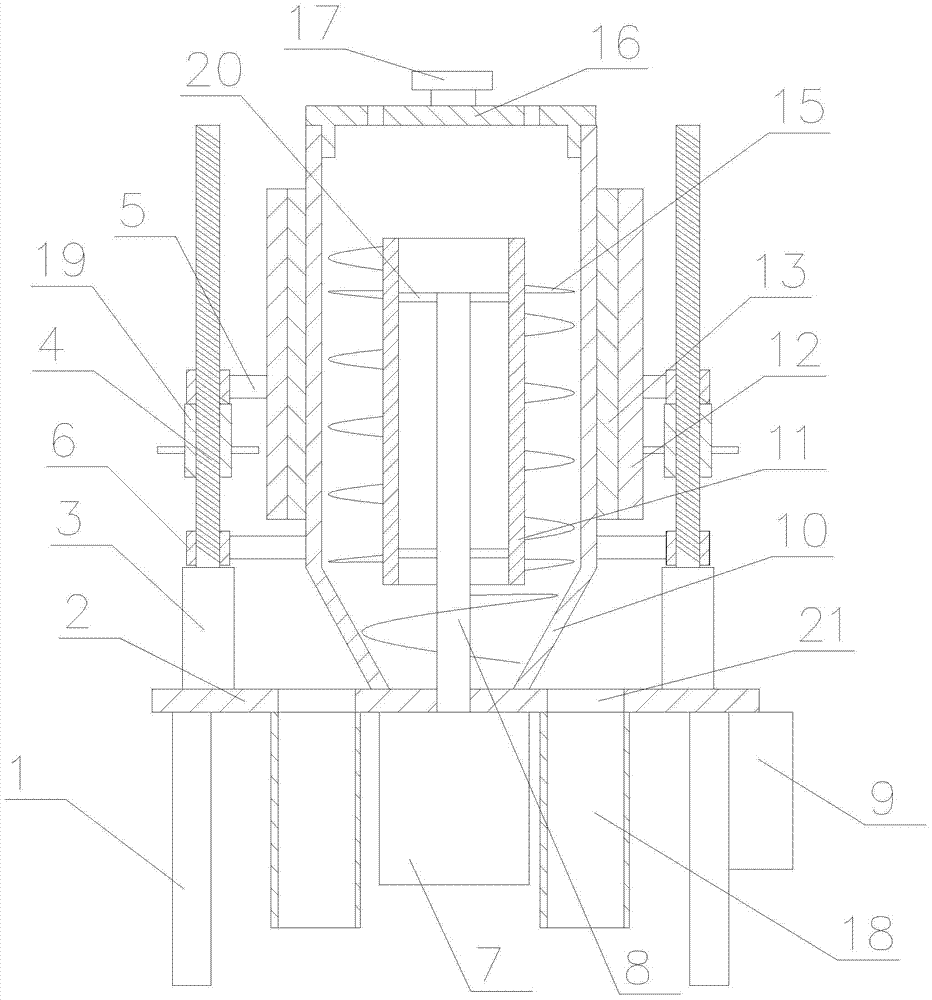

Pyrolysis device

ActiveCN104164249BHigh thermal efficiencyHeating up fastIndirect heating destructive distillationLiquid hydrocarbon mixture productionSingle processEngineering

The invention discloses a pyrolyzer which comprises a pyrolyzing furnace, a cooler assembly and a gas storage tank, wherein the pyrolyzing furnace comprises a furnace body, two cloth boards and a heating radiation tube; the furnace body is provided with an oil-gas outlet; the two cloth boards are separately arranged in the furnace body in the up-and-down direction; each cloth board is provided with a plurality of through holes which are penetrative in the thickness direction; and the heating radiation tube is arranged in the furnace body and positioned between the two cloth boards. The cooler assembly is connected with the oil-gas outlet. The gas storage tank is connected with the cooler assembly and used for receiving pyrolysis gas. The pyrolyzer accelerates the material heating, enables the material to be heated uniformly, does not have coking, effectively increases the single-process treatment capacity, can fully utilize the radiation heat of the heating radiation tube, and has higher heat efficiency; and thus, the pyrolyzer is convenient for releasing the oil-gas mixture, and the generated oil-gas mixture contains fewer solid products, thereby avoiding the blockage of the oil-gas outlet.

Owner:SHENWU TECH GRP CO LTD

Electrostatic centrifugal sesame oil filter

The invention relates to the technical field of sesame oil processing and manufacturing equipment, and discloses an electrostatic centrifugal sesame oil filter, comprising a case, an oil storage tankand a centrifugal cavity, wherein four groups of vertical evaporation pipes are movably connected to the top of the case in an annular distribution manner; the sides, close to the center of the case,of the evaporation pipes are fixedly connected with a vertical hydraulic rod through connecting rods; heating plates for heating sesame oil input into the evaporation pipes to evaporate water are fixedly mounted on the inner side walls of the evaporation pipes; the inner sides of centrifugal frames are connected to the side face of a vertical centrifugal rod arranged at the inner middle part of the case; the bottom of the centrifugal cavity downwards communicates with a filtering pipeline with a bottom end inclining towards the center of the case; the bottom end of the filtering pipeline extends to a position above the oil storage tank which is fixed to the center of the inner bottom of the case; the middle part of the centrifugal cavity is of an ellipsoid structure; and a circle of a centrifugal net used for separating sesame oil from impurities in the sesame oil is arranged at the middle part of the ellipsoid structure. The electrostatic centrifugal sesame oil filter has the advantages that the parts of the filter are convenient to assemble and disassemble, the purity of treated sesame oil is high, and single-time treatment capacity is large.

Owner:安徽省鹰鹭麻油有限公司

Device and method for sputtering and depositing metal on surface of magnetic powder material

ActiveCN114318269AUniform depositionLarge amount of single processingTransportation and packagingVacuum evaporation coatingSputter depositionPower apparatus

The invention relates to the technical field of vacuum surface coating, in particular to a device and method for sputtering and depositing metal on the surface of a magnetic powder material. The device comprises a vacuum cavity, a vacuum pump set, a magnetron sputtering target, a cathode ion source, a water-cooled anode and a sample containing component arranged in the vacuum cavity, the sample containing component is a sample roller, the axis of the sample roller is arranged in the horizontal direction, and the sample roller can rotate around the axis of the sample roller; the two ends of the sample roller are opened, and the power device can drive the sample roller to rotate; the cathode ion source and the magnetron sputtering target inwards extend into the sample roller from the opening at the same end of the sample roller; and the water-cooling anode inwards extends into the sample roller from the opening at the other end of the sample roller. The device provided by the invention can realize high-speed uniform deposition on the surface of the magnetic powder material, improves the treatment efficiency, and is suitable for industrial production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Smelting plant waste tailing treatment technology and equipment

InactiveCN109182766ARealize continuous productionLarge amount of single processingCellsProcess efficiency improvementElectricityElectrolysis

The invention relates to a smelting plant waste tailing treatment technology and further relates to equipment used for achieving the smelting plant waste tailing treatment technology. The equipment comprises a plurality of electrolytic bath boxes which are arranged in a ladder shape. The interior of each box is partitioned through two partition plates arranged in a spaced mode, wherein through holes are formed in the partition plates correspondingly, filter nets are embedded in the through holes correspondingly, two anode plates are located between the two partition plates, anode grooves are formed between the anode plates and the corresponding partition plates correspondingly, two cathode plates are located on the outer sides of the partition plates correspondingly, cathode grooves are formed between the cathode plates and the corresponding partition plates, and an electric mixer is arranged between the two anode plates. A conveying pipe group used for conveying an electrolysis mixture is fixedly connected between every two boxes. By applying the electrolysis equipment and the corresponding electrolysis technology provided by the invention, the hazardous tailing treatment cost canbe lowered for enterprises, in addition, electric chlorination continuous production is achieved while the substance gold is obtained, and the treatment technology and equipment can be widely appliedto the technical field of electrolysis technologies and electrolysis equipment.

Owner:张润芳

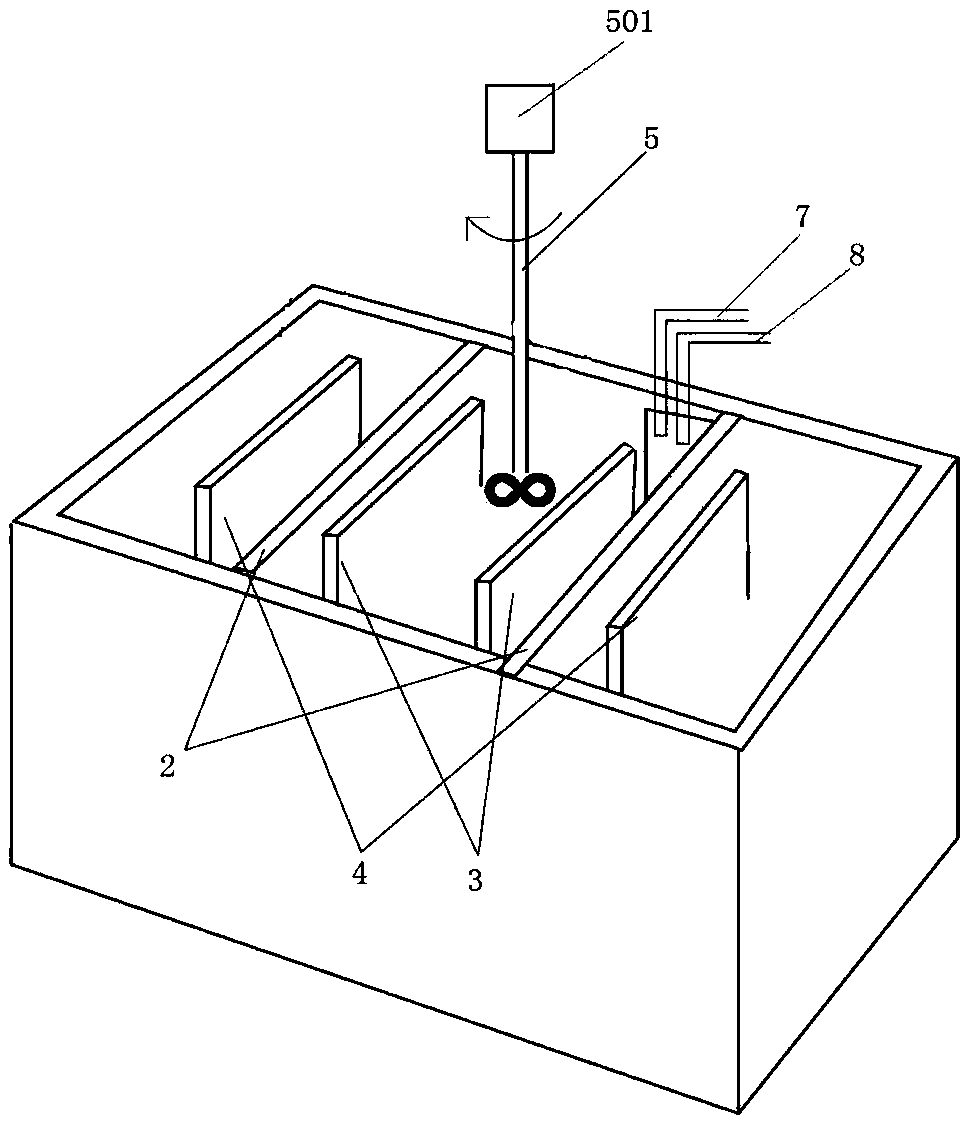

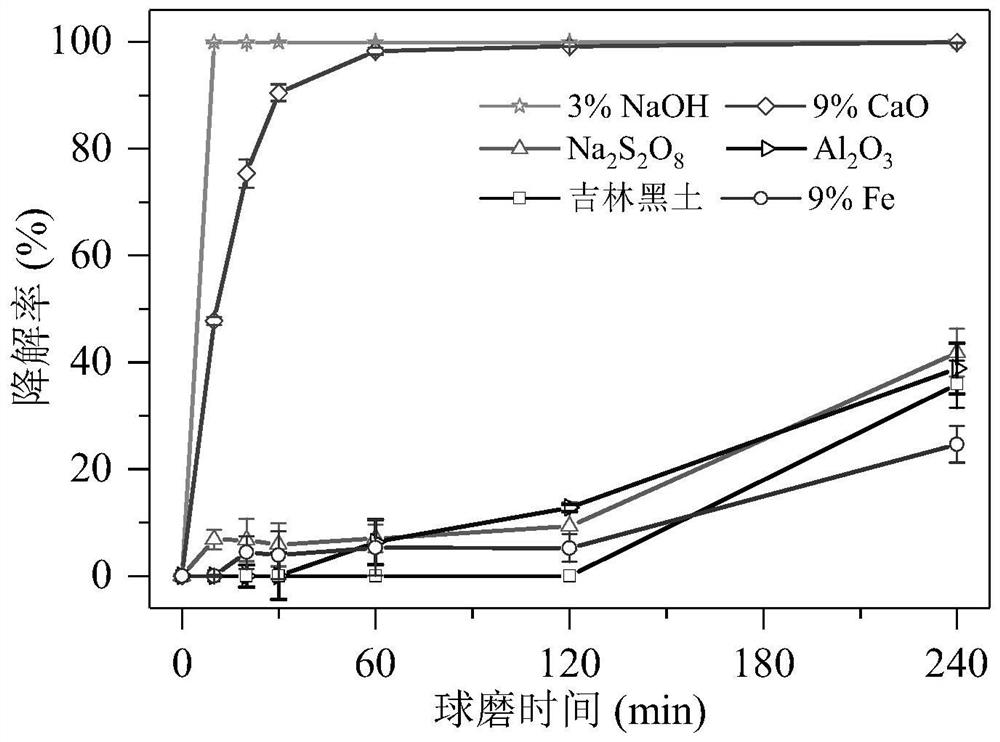

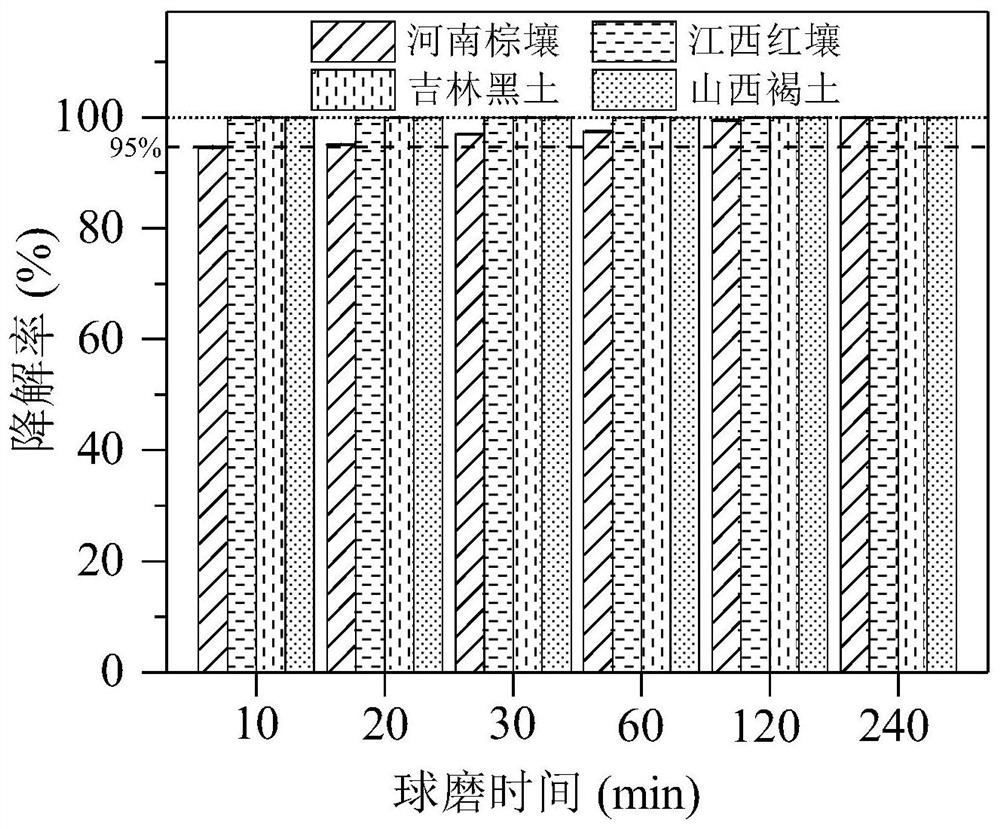

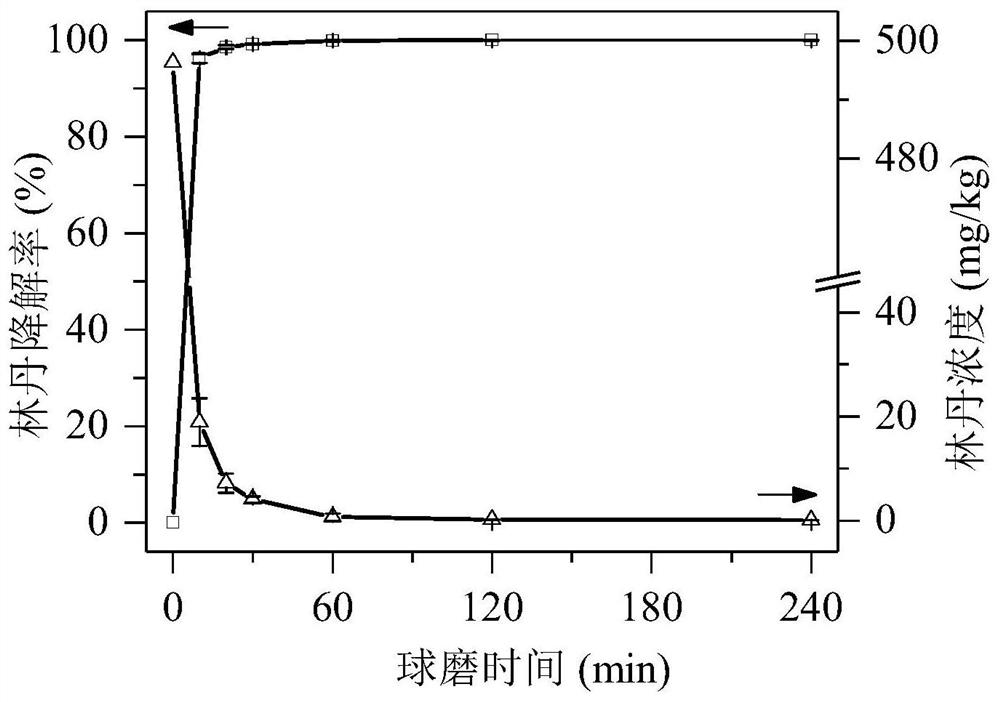

Method for degrading lindanee in different types of soil by using additive in cooperation with mechanochemical method

PendingCN113814264APromote degradationGuaranteed degradabilityContaminated soil reclamationGrain treatmentsSoil scienceEngineering

Owner:BEIJING NORMAL UNIVERSITY

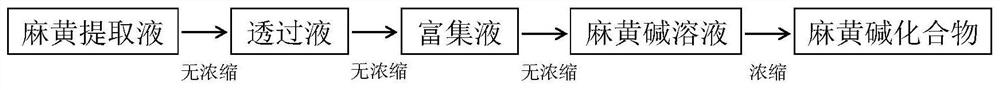

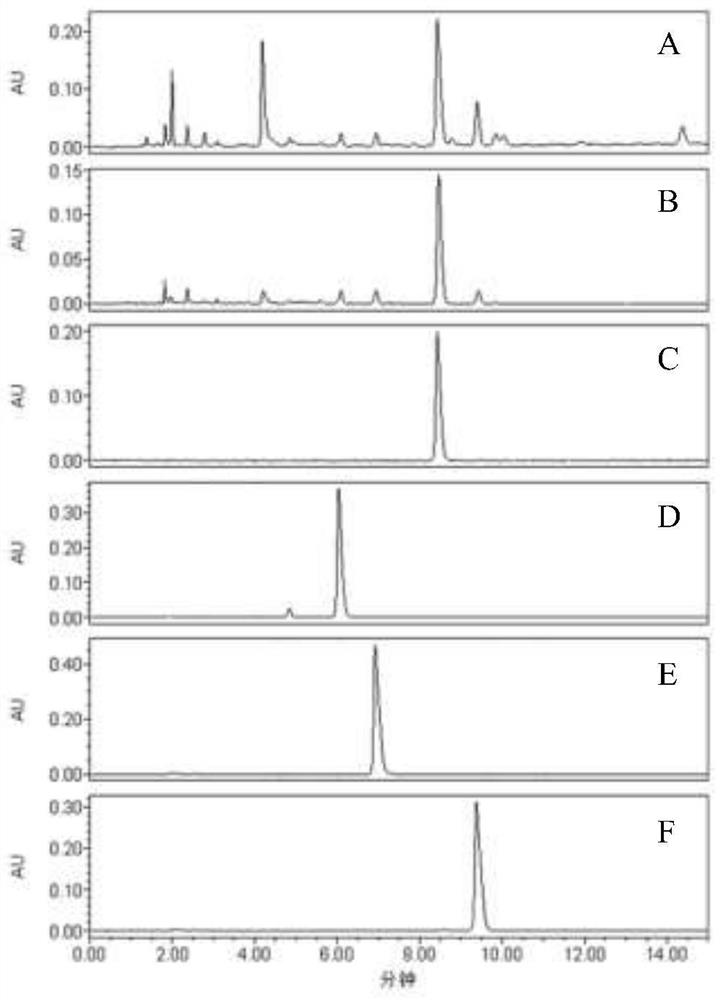

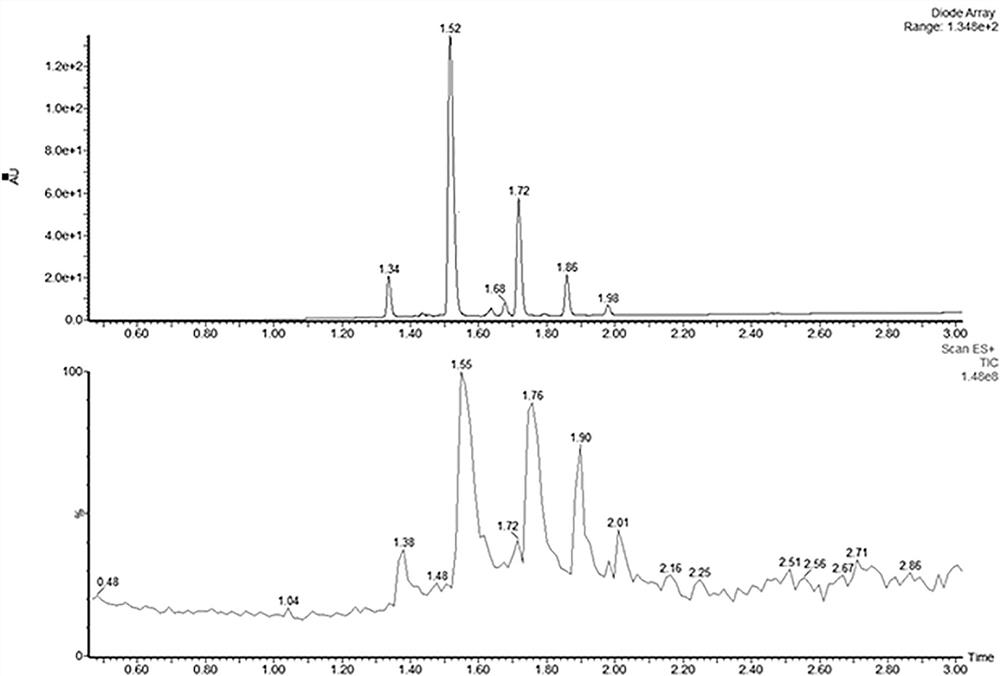

Continuous preparation method for extracting ephedrine from ephedra

PendingCN114133335AHigh purityIncrease contentOrganic compound preparationAmino-hyroxy compound preparationBiotechnologyUltrafiltration

The invention provides a method for efficiently separating and purifying four alkaloids such as ephedrine from ephedra. Specifically, an ephedra medicinal material extracting solution passes through an ultrafiltration membrane to obtain a permeate, the permeate is enriched by a reversed-phase column 1 to obtain an enriched solution, and the enriched solution is purified by a reversed-phase column 2 to obtain four alkaloid compounds such as ephedrine and the like. The method is characterized in that a running water type continuous preparation technology for extracting ephedrine from ephedra is introduced, and four alkaloids such as high-purity ephedrine can be obtained only through one-time concentration; according to the method, the content of ephedrine is increased from about 2% to about 24% through enrichment of the reversed-phase column 1, the ephedrine with the purity of 99% is obtained through purification of the reversed-phase column 2, the recovery rate can reach 80%, meanwhile, three alkaloids including pseudoephedrine, demethylated ephedrine and demethylated pseudoephedrine are obtained, and the method is rapid, efficient, easy and convenient to operate and beneficial to industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

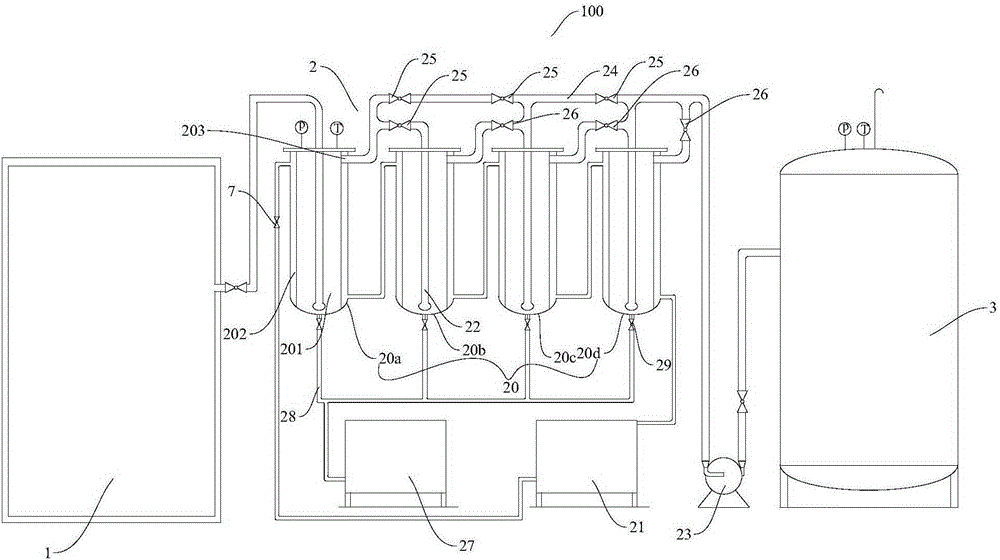

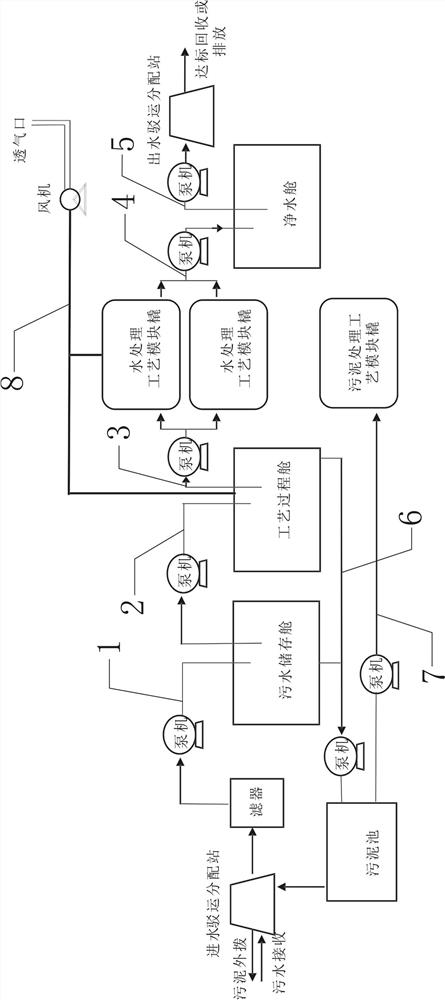

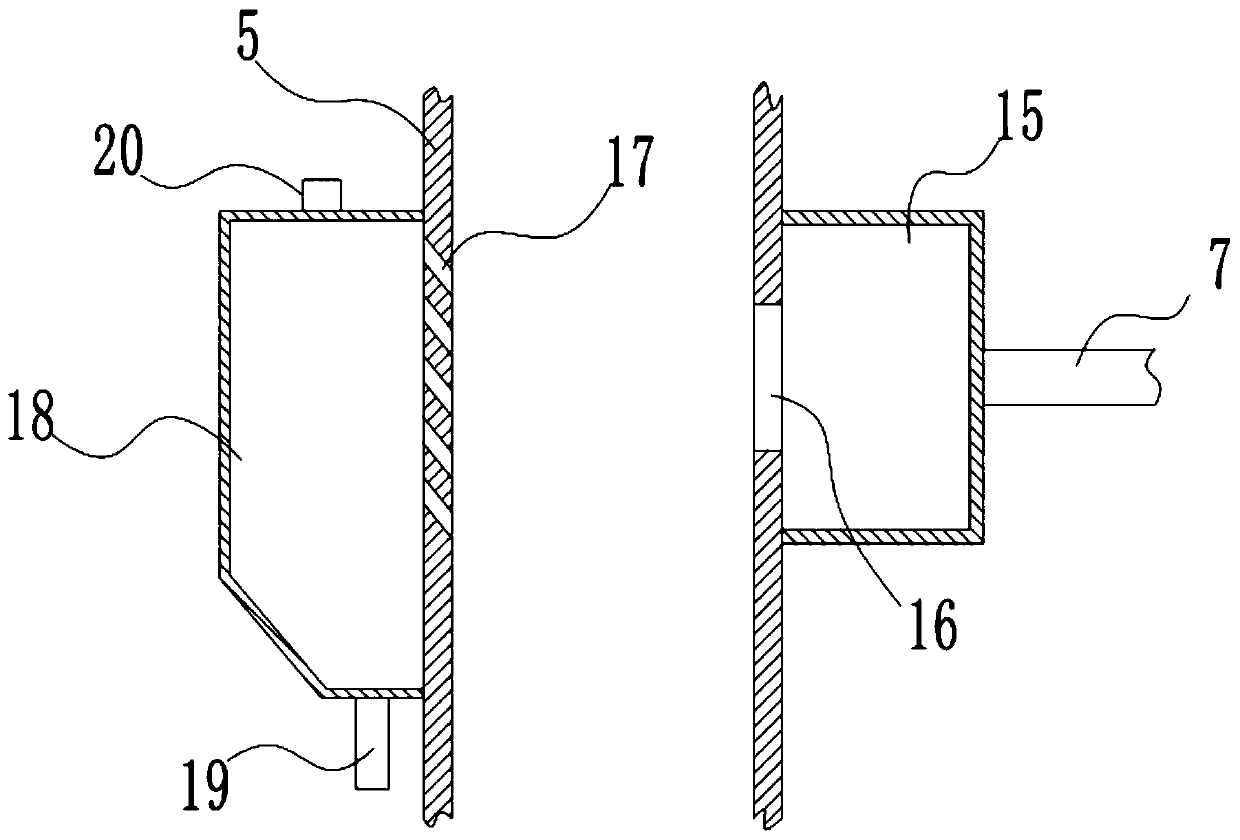

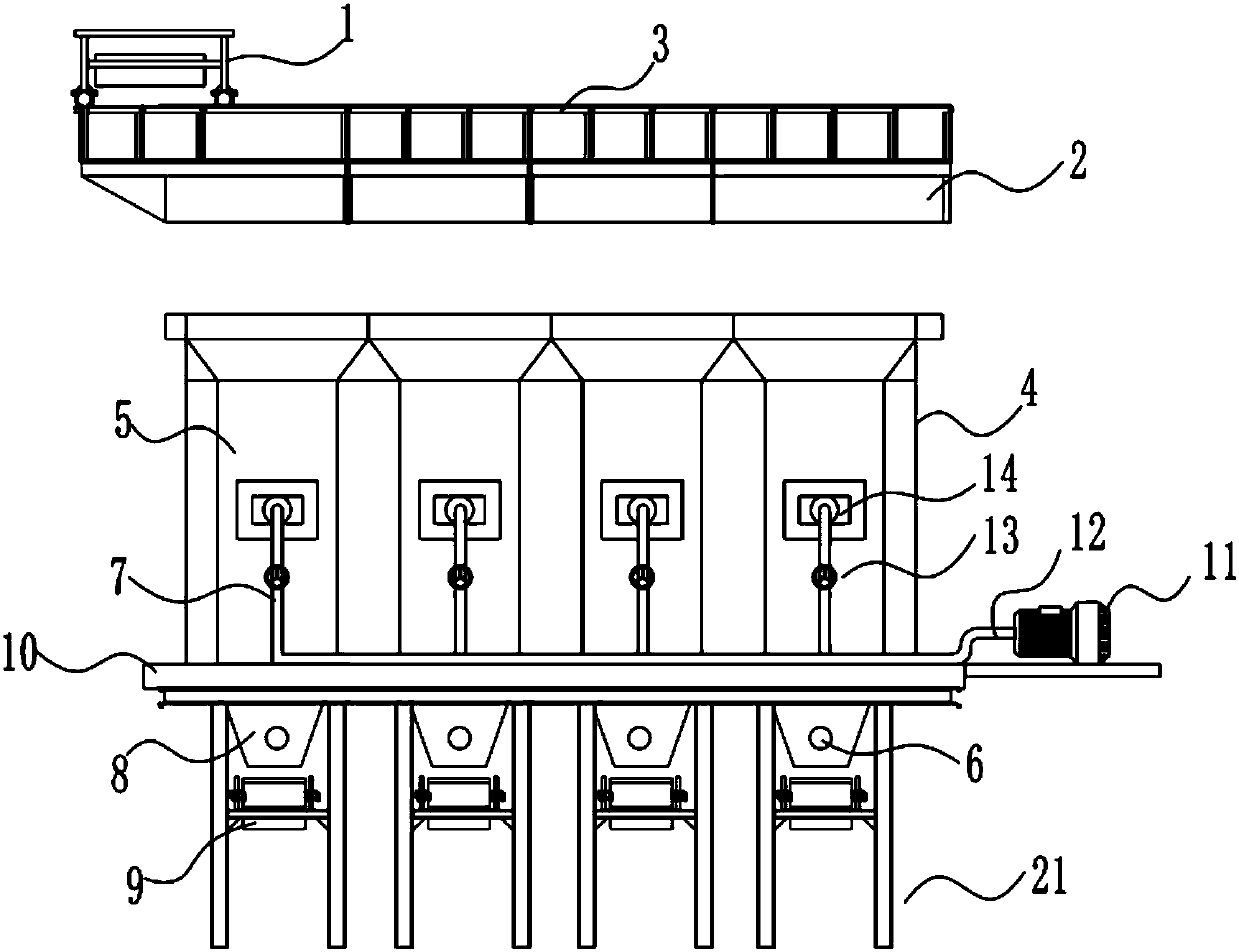

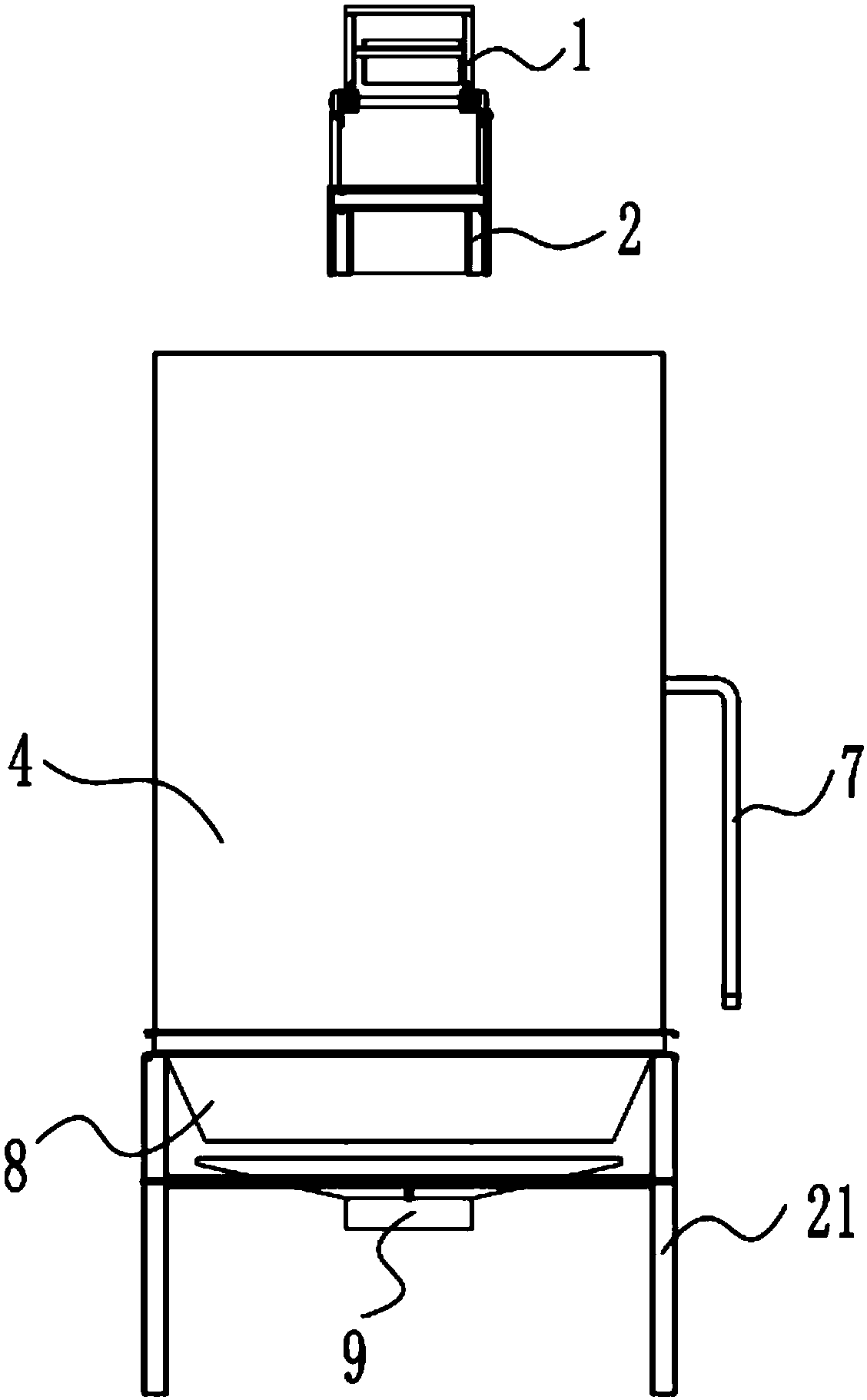

Modular overwater sludge water treatment system

InactiveCN114044582AFlexible moving processLarge amount of single processingTreatment involving filtrationMultistage water/sewage treatmentProcess systemsSewage treatment

The invention provides a modular overwater sludge water treatment system, which relates to the field of offshore sewage treatment equipment. According to a sewage treatment flow, an inflow lightering distribution station, a sewage storage cabin, a technological process cabin, a water treatment technological module skid, a sludge treatment technological module skid, a water purification cabin and an outflow lightering distribution station are sequentially arranged on a ship body; compared with a land distributed sewage treatment system, the overwater sludge water treatment system has the advantages of flexibility in movement, large single-time treatment capacity, few influence factors, maneuverability, high efficiency, convenience in docking with land users and the like, can be particularly used in a flood period, independently forms a sewage treatment system, and can adjust a sludge water process system according to the convenience needs of customers. As a supplementary facility of land sewage treatment engineering, the treatment system disclosed by the invention still belongs to an application blank.

Owner:CNOOC ENERGY TECH & SERVICES

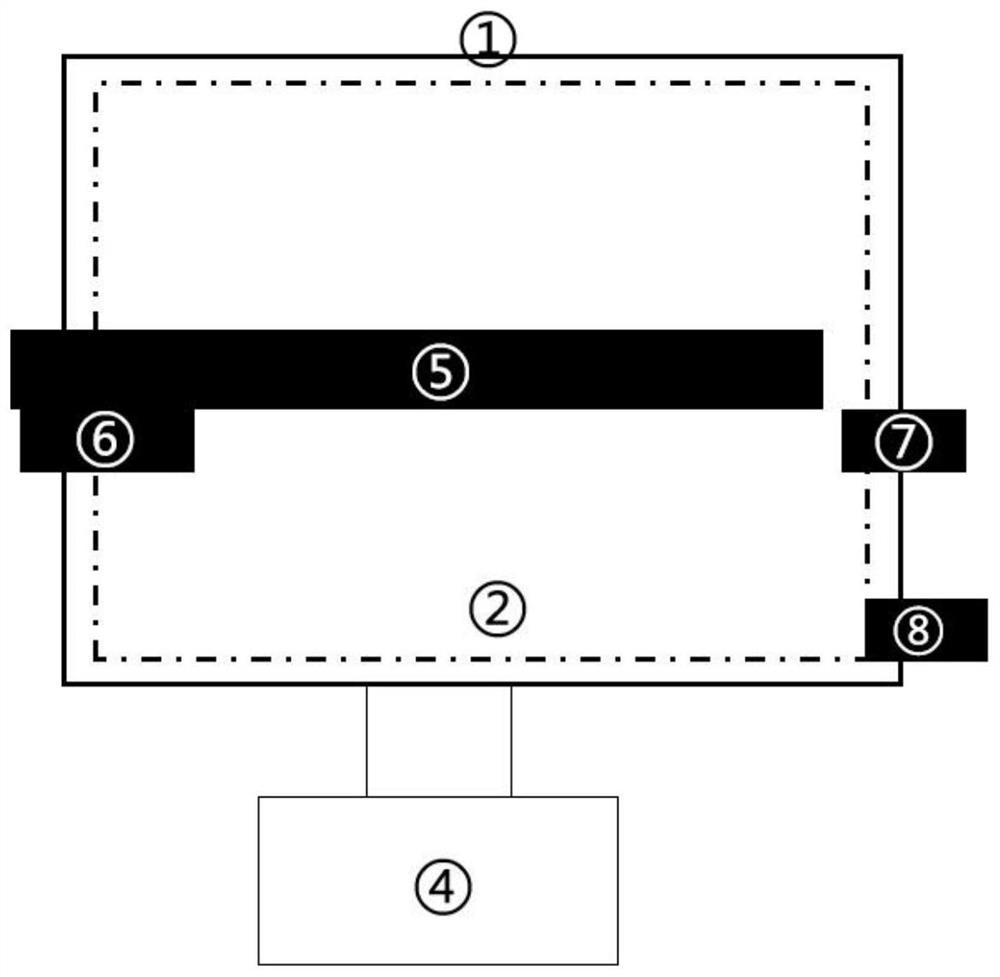

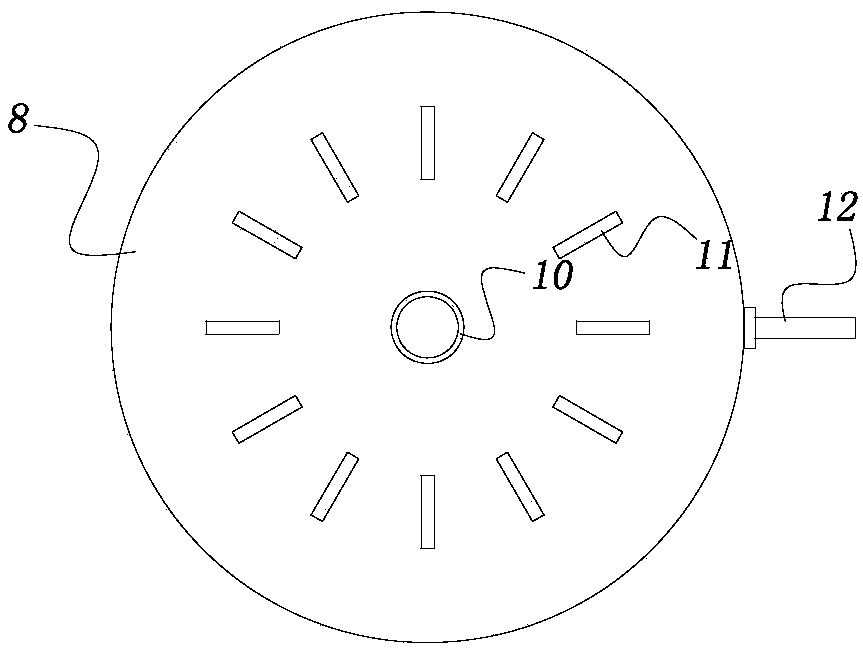

Band saw grinding butting device

InactiveCN109986362ASimple structural designLarge amount of single processingMetal sawing tool makingOther manufacturing equipments/toolsEngineeringDrive motor

The invention belongs to the technical field of machining equipment, and particularly relates to a band saw grinding butting device. The band saw grinding butting device comprises a bottom plate supported by supporting stand columns, a vertical center rod is fixedly connected to the middle part of the bottom plate, and two rotating disk bodies are arranged on the center rod from top to bottom in apenetrated mode. The rotating disk bodies each comprise a flat cylindrical disk body, a shaft hole is formed in the center of each disk body, and central sleeves are fixedly connected into the shaftholes. The central sleeves are arranged on the center rod in a sleeving mode, a plurality of band saw blade inserting holes are formed in the middle parts of the disk bodies at equal angular intervalsin the circumferential direction, and hand shifting levers are fixedly connected to the outer edges of the disk bodies. A circular groove for accommodating the bottom of the rotating disk bodies is further formed in the bottom plate, and a circular through hole which is aligned with the band saw blade inserting holes in an up-down mode is formed in the bottom wall of the groove. A cutter is fixedly connected to the lower surface of the bottom plate and the lower part of the circular through hole, and a grinding roller is mounted through a shaft seat. The grinding roller is disposed to be tangent to the lower surface of the bottom plate, and a driving motor driving the grinding roller to rotate is further mounted on the corresponding supporting stand column.

Owner:天津正和瑞科技有限公司

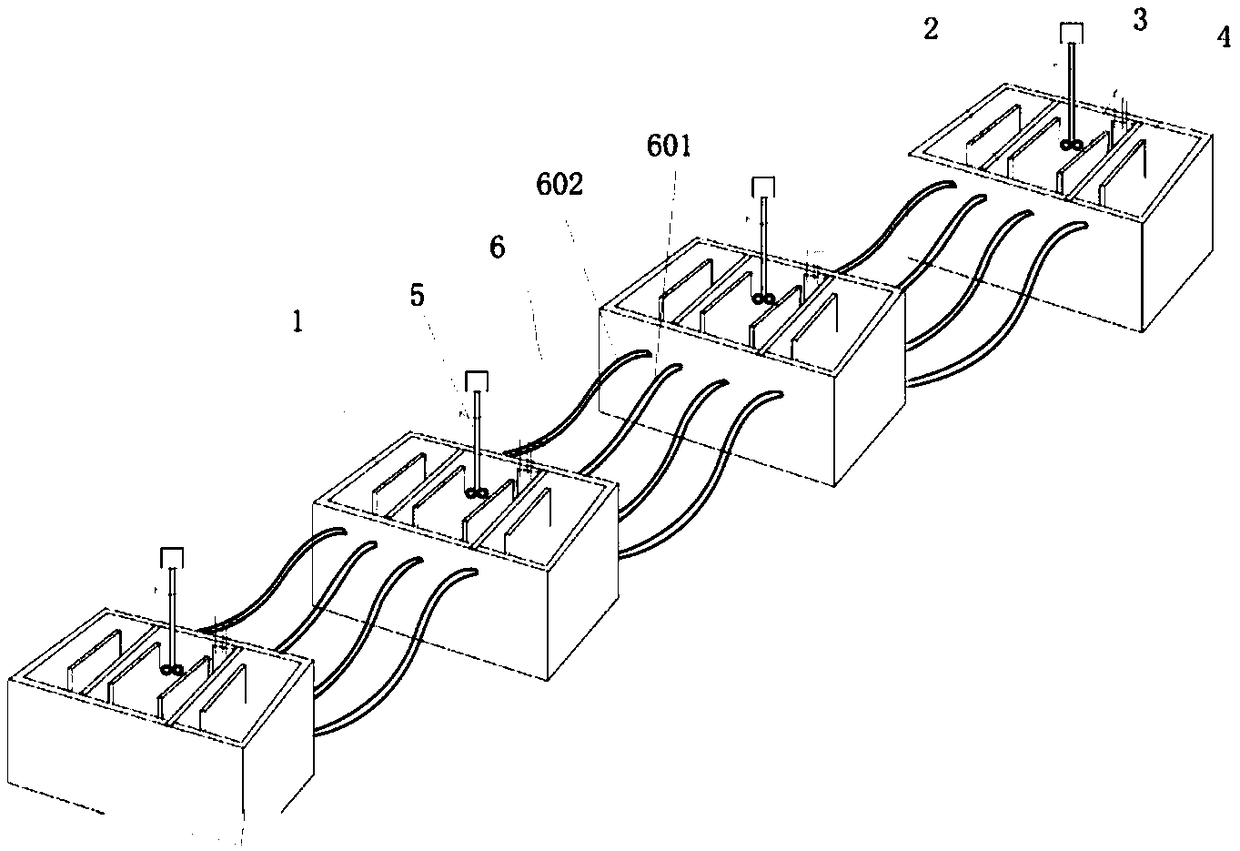

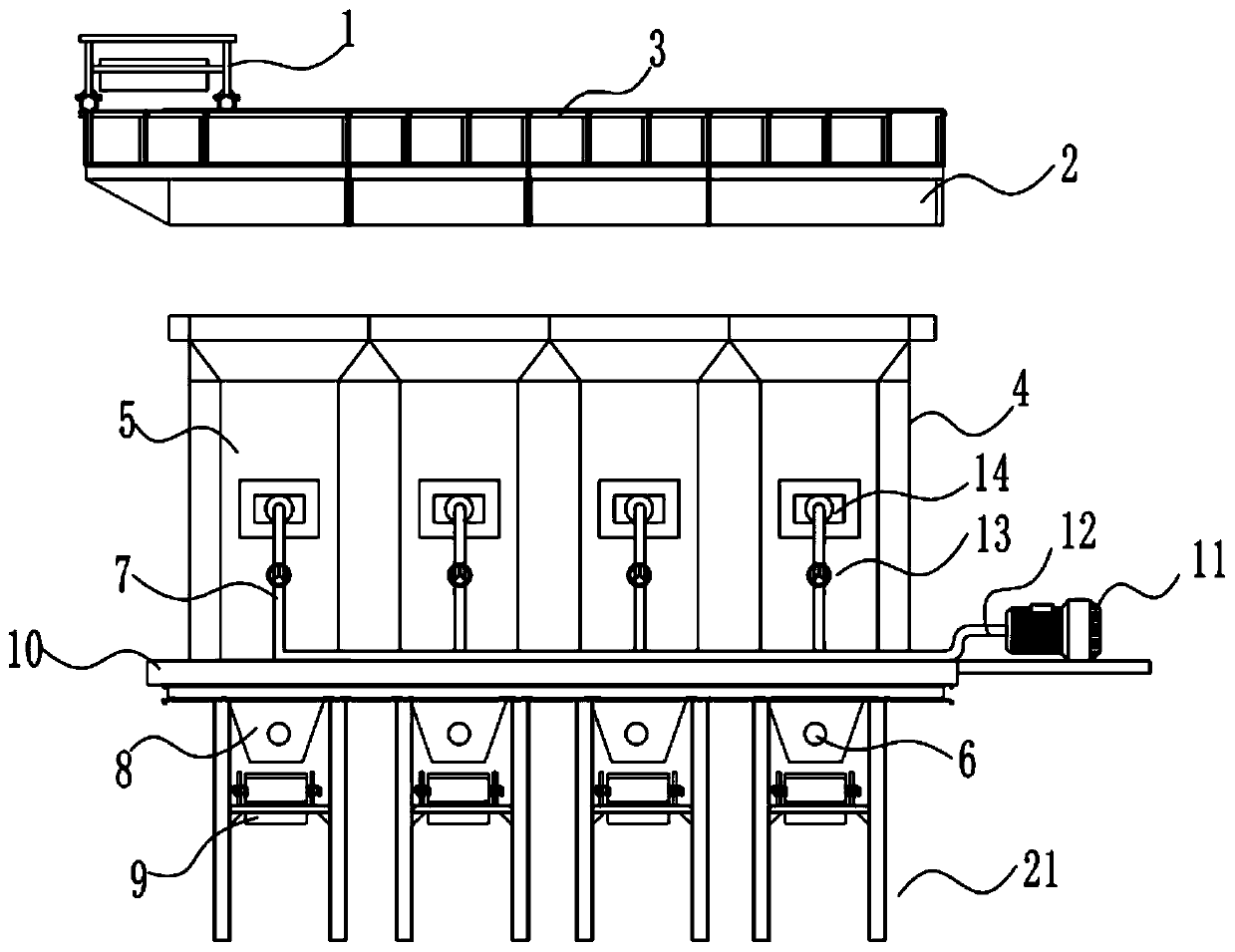

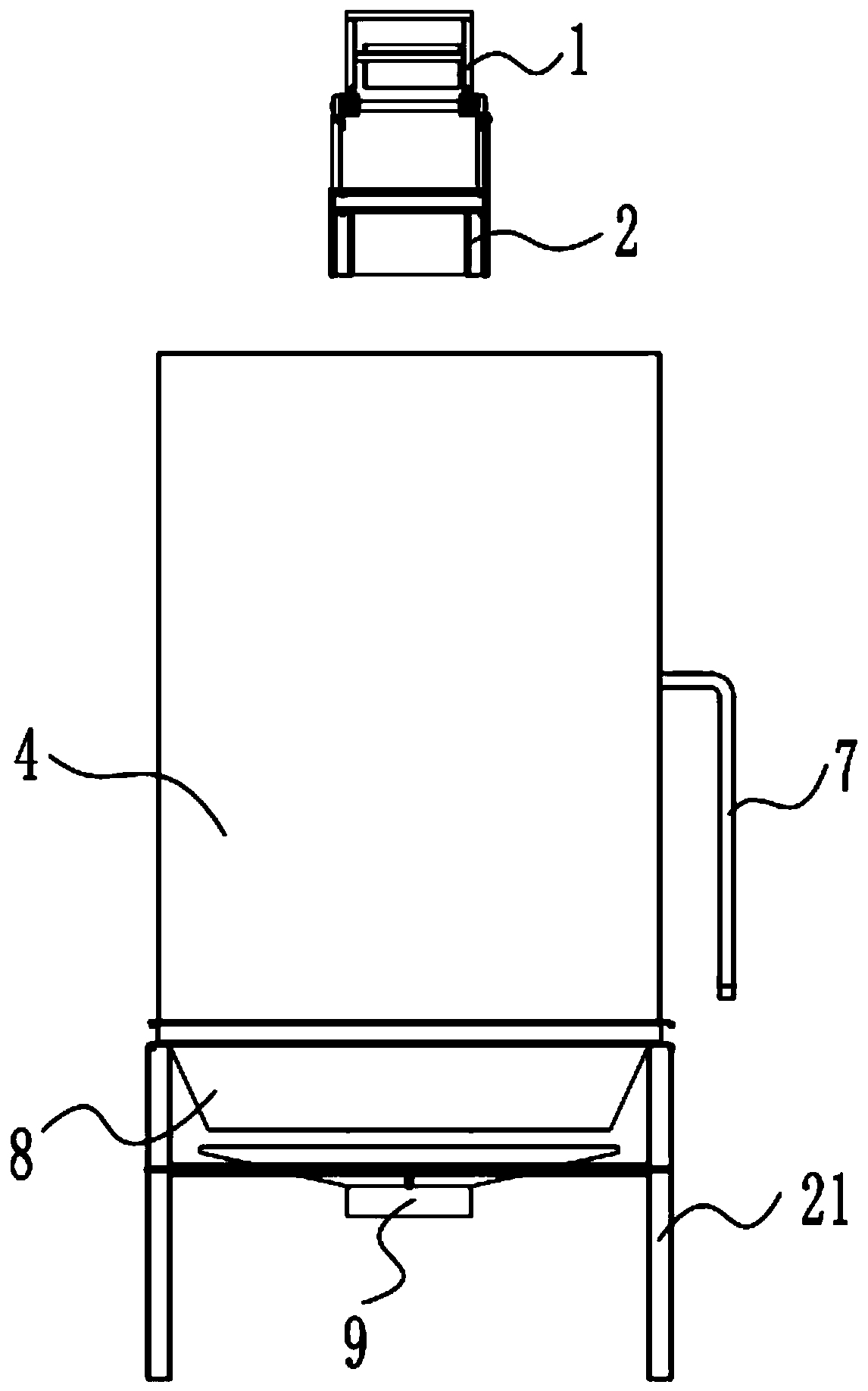

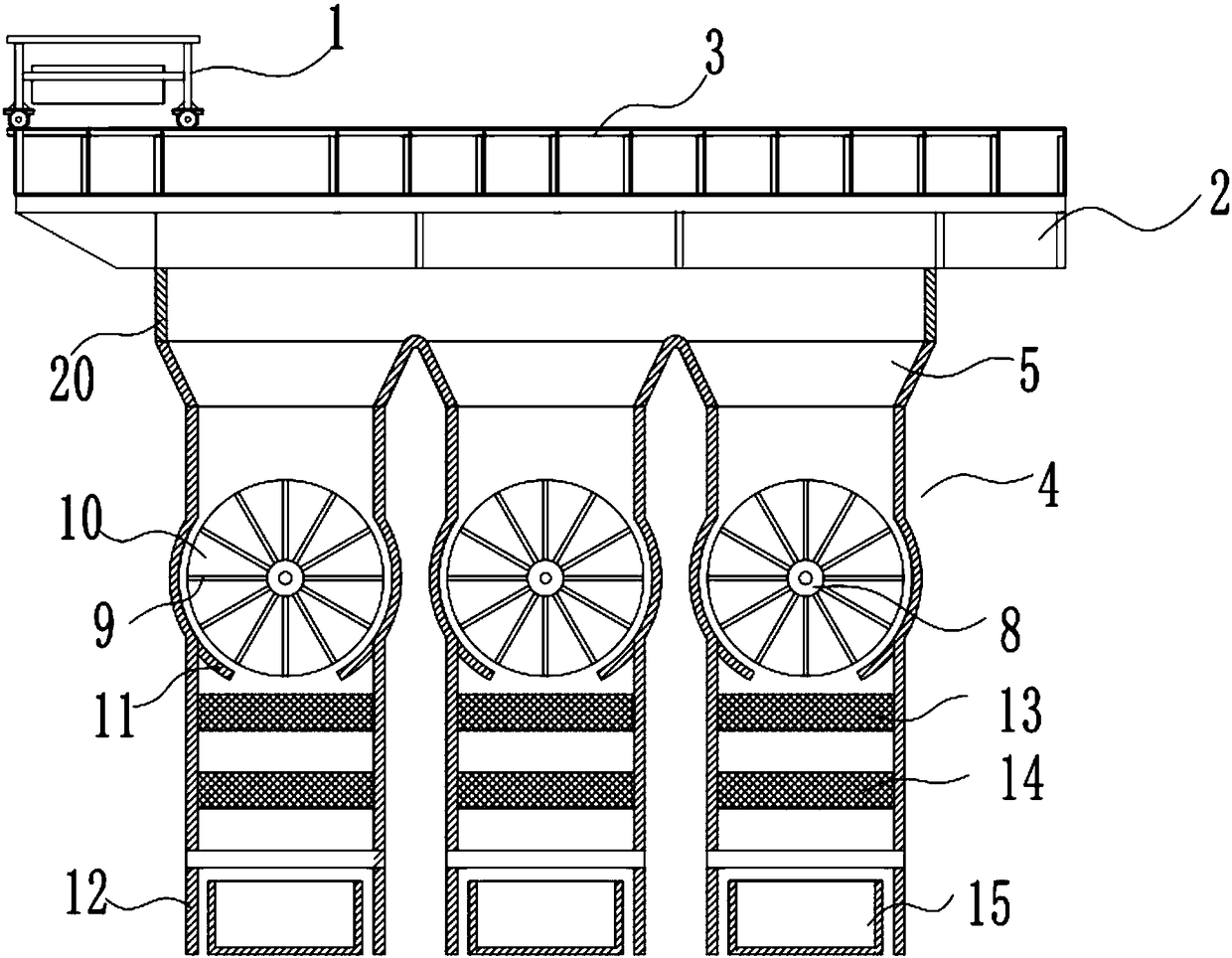

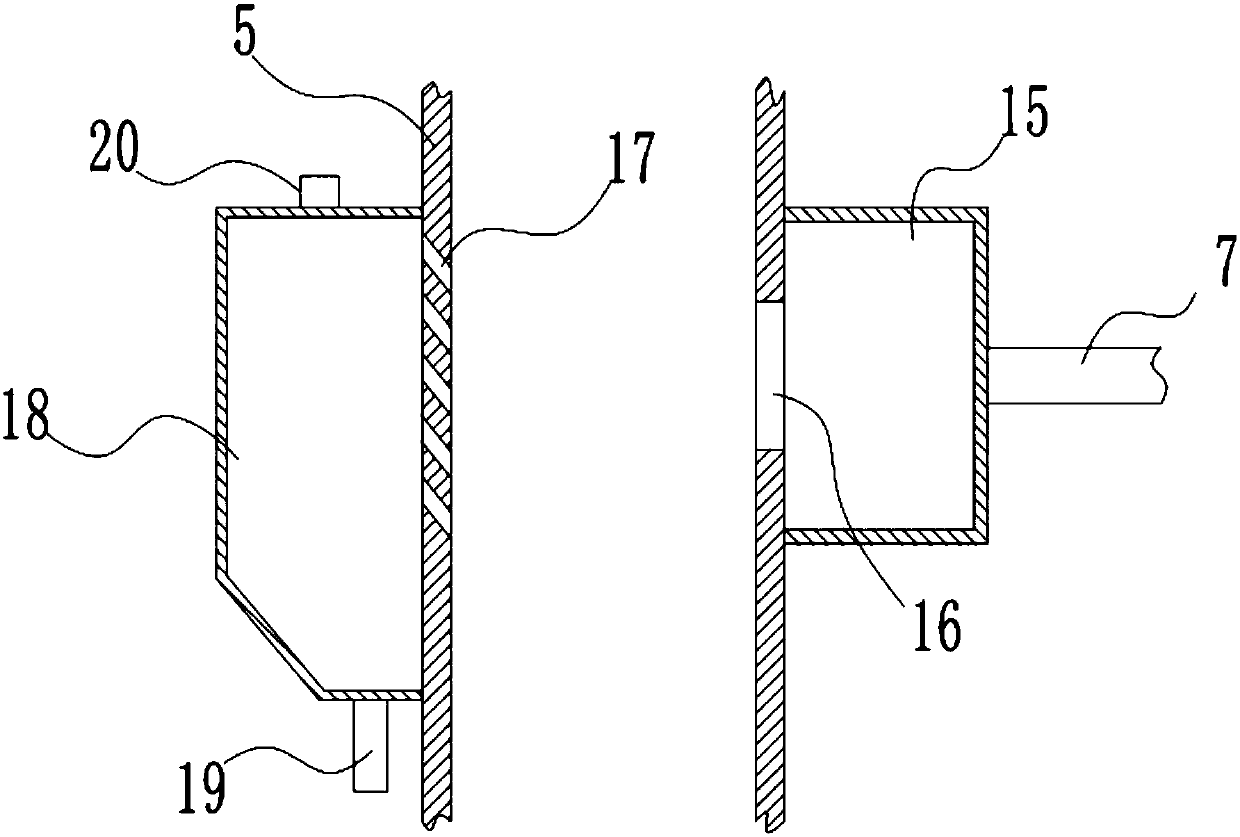

A high-efficiency grain wind impurity removal device

ActiveCN107694929BImprove efficiencyLarge amount of single processingGas current separationThermodynamicsEngineering

The invention discloses an efficient grain wind power impurity removing device. The efficient grain wind power impurity removing device comprises a distributing vehicle, a distributing vehicle truss,a shell, impurity removing barrels and a supporting frame; a platen is fixedly installed at the top of the supporting frame and is fixedly provided with a cylindrical shell, the impurity removing barrels which are continuously arranged in a linear manner are arranged inside the shell, a discharging hopper is fixedly connected to the bottoms of the impurity removing barrels and extends out from thelower surface of the platen, and a material collecting hopper is installed at the position, corresponding to the discharging hopper, of the supporting frame; and a draught fan is further installed onthe platen, an air pipe is installed at the air outlet pipe of the draught fan, the air pipe is connected with multiple air inlet branches, the air inlet branches penetrate the shell and are connected with an air box on the outer side of the impurity removing barrels, and the air box is provided with an air inlet flange used for being connected with the air inlet branches. The efficient grain wind power impurity removing device has the beneficial effects that grain is evenly distributed into the impurity removing barrels through the distributing vehicle, impurity removing operation is carriedout through the multiple impurity removing barrels, efficiency is high, and the one-time processing amount is large.

Owner:双峰县富强机械科技有限公司

Sand screening device with constant-weight feeding function for large-scale buildings

InactiveCN108100692AAchieve constant feedLarge amount of single processingSievingGas current separationScreening effectEngineering

The invention discloses a sand screening device with a constant-weight feeding function for large-scale buildings. The sand screening device comprises a material distributing vehicle, a rail support,screening boxes and a material collection box, wherein two parallel material distributing vehicle rails are arranged on the rail support; the material distributing vehicle for distributing materials is arranged on the material distributing vehicle rails; a plurality of screening boxes arranged in the length directions of the material distributing vehicle rails are arranged directly below the railsupport; a discharging hopper is fixed on the top of the each screening box; a speed reducing motor is fixed on one side of the each screening box; and a rotary shaft arranged at the output end of theeach speed reducing motor extends into the corresponding screening box. The sand screening device disclosed by the invention has the following beneficial effects that because a space of a storage grid is definite, raw sand which is fallen off from an epitaxial plate every time is definite when the speed reducing motors keep rotating at constant speed, so that the the raw sand fallen into a firstscreen mesh is fixed and constant feeding is realized; a screening effect cannot be affected by sudden change of a raw sand amount; and moreover, the sand screening device wholly consists of the plurality of screening boxes, and the single handling capacity is large.

Owner:长沙双合盛企业管理有限公司

Method for removing organic solvent residual in raw medicine

InactiveCN101406765BAvoid destructionAvoid secondary pollutionSolvent extractionOrganic solventSorbent

The invention discloses a method for removing residual organic solvents from a bulk drug, which comprises the following steps: firstly, extracting the bulk drug for 0.5 to 2 hours statically and then extracting the bulk drug for 0.5 to 6 hours dynamically under the condition that the temperature is between 35 and 80 DEG C and the pressure is between 10 and 40 MPa, so as to obtain a bulk drug finished product of which the residual organic solvent accords with the limit standard in an extraction kettle; secondly, decompressing and separating carbon dioxide flowing out of the extraction kettle under the condition that the pressure is between 4 and 7 MPa and the temperature is between 25 and 45 DEG C, collecting depositions in a separating kettle, and reclaiming the bulk drug in the depositions for reuse in the extraction kettle. The carbon dioxide flowing out of the separating kettle is adsorbed and separated by using an adsorbent, and the obtained carbon dioxide is introduced to the extraction kettle for recycling. The residual organic solvent in the bulk drug finished product obtained by the method accords with the limit standard, the yield of the bulk drug is high, and the carbon dioxide can be recycled. The method has the advantages of simple process, stable operation, economy and high efficiency, and suitability for industrial application.

Owner:ZHEJIANG UNIV

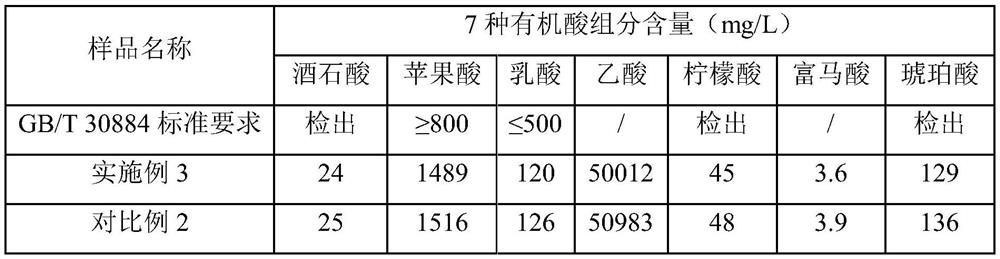

Bi-component apple vinegar beverage main agent as well as preparation method and application thereof

PendingCN111700193AReduce batching processWell mixedFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentBiotechnologyHigh-fructose corn syrup

The invention discloses a bi-component apple vinegar beverage main agent. The beverage main agent comprises a main agent A and a main agent B. The main agent A comprises concentrated apple vinegar, high fructose corn syrup A, honey, sodium citrate A and caramel color A in a specific ratio, and the main agent B comprises apple vinegar, edible salt, sucralose, sodium citrate B, caramel color B and edible essence in a specific ratio. By mixing and concentrating ingredients with great influence on taste and flavor in advance, an apple vinegar beverage with consistent flavor and stable quality canbe obtained according to standardized operation, and the beverage is low in transportation cost and good in storage performance. The invention further discloses a preparation method of the bi-component apple vinegar beverage main agent, the beverage main agent is stable in performance, easy and convenient to operate and high in production efficiency, and large-scale production can be achieved. Theinvention also discloses an application of the bi-component apple vinegar beverage main agent in rapid preparation of apple vinegar beverages, rapid blending production of the apple vinegar beveragesin different beverage factories can be realized, and the flavor and the quality are stable.

Owner:广东天地壹号食品研究院有限公司

A method for enriching fish oil epa and dha by low-temperature crystallization

ActiveCN107629873BLower requirementKeep natural activityFatty-oils/fats refiningCarboxylic compound separation/purificationOrganic solventFiltration

The invention relates to a method for enriching fish oil EPA and DHA by low temperature crystallization, and belongs to the technical fields of aquatic product processing and health care products. Themethod comprises the following steps: pretreating fish oil, and then adding an organic solvent and a nucleation assisting agent in the fish oil, wherein the mass ratio of the fish oil to the organicsolvent to the nucleation assisting agent is 100 to (200-1000) to (0.5-2); mixing evenly, carrying out low temperature crystallization, carrying out vacuum suction filtration and separation of a crystal and a non-crystallized liquid, then removing the organic solvent and the nucleation assisting agent in the non-crystallized liquid, and thus obtaining the enriched fish oil EPA and DHA. The methodfor enriching the fish oil EPA and DHA by low temperature crystallization has the advantages of simple equipment, easy operation, large single treatment quantity and low cost, allows effective components not to easily undergo oxidization, isomerization, polymerization and other reactions, and is well able to maintain the natural activity of the EPA and DHA.

Owner:FUNCTION (QINGDAO) MARINE TECH CO LTD

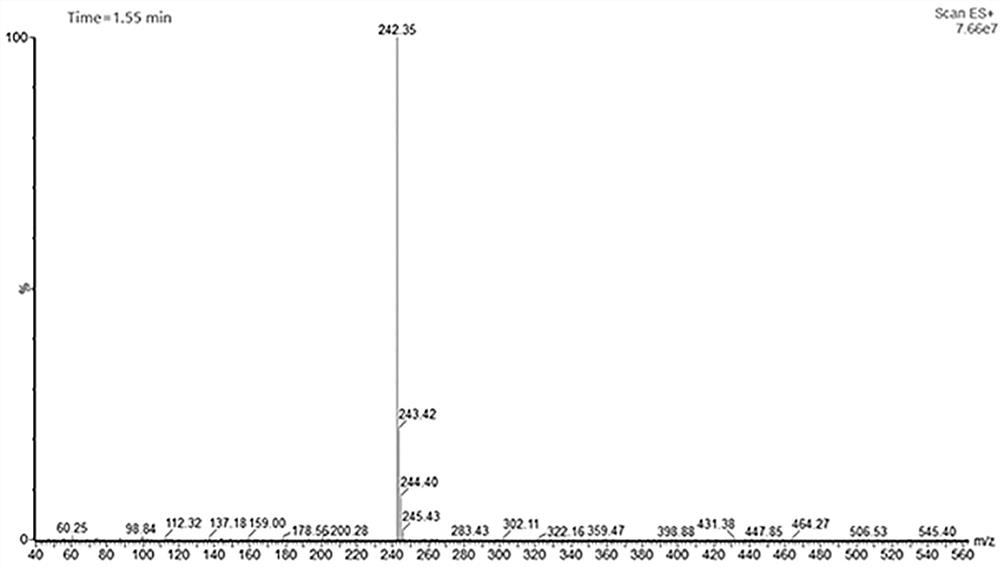

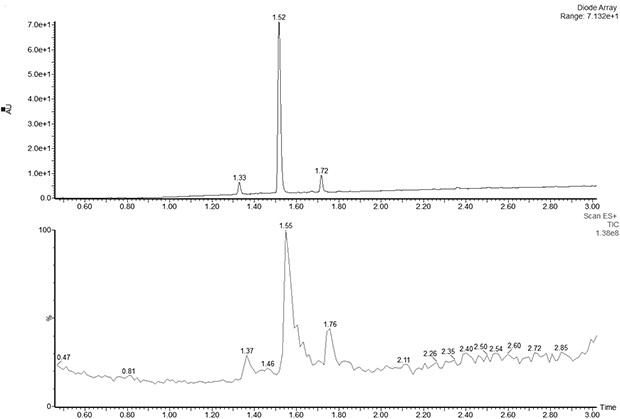

Purification method of electron mediator azure c

ActiveCN114507193BHigh purityIncrease productionOrganic chemistryMaterial analysis by electric/magnetic meansBiochemistryMedicinal chemistry

The invention provides a method for purifying an electron mediator azure C, comprising the following steps: taking low-purity azure C, using fluorenylmethoxycarbonyl chloride as an amino-protecting reagent to react with azure C to obtain amino-protected electrons After deprotection of the medium, high-purity azure C can be obtained. The purification method of the present invention has a large amount of single treatment, and the output of the obtained high-purity product is also large, which can effectively meet the preparation requirements of biosensors for blood sugar detection and the like, and improve production efficiency.

Owner:GENCLONN BIOTECH HANGZHOU

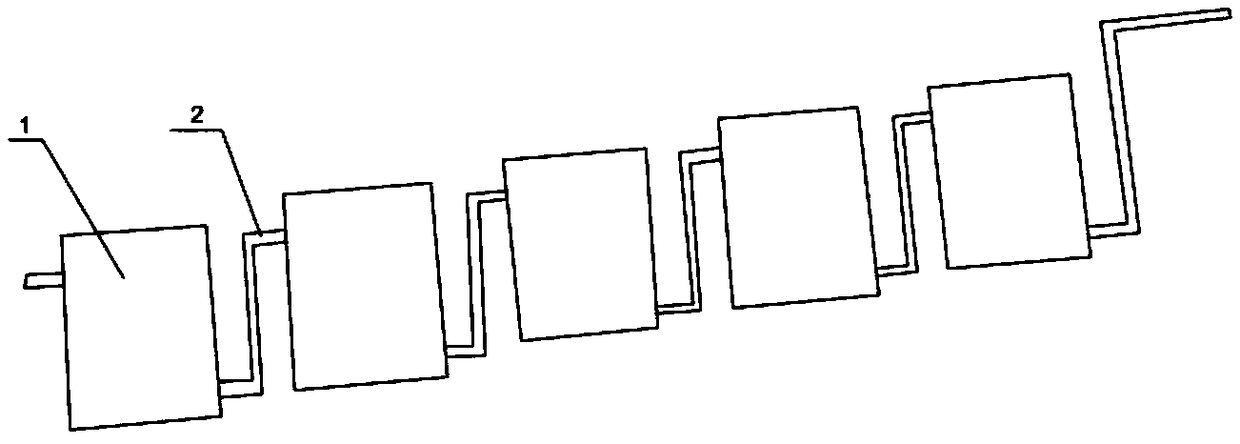

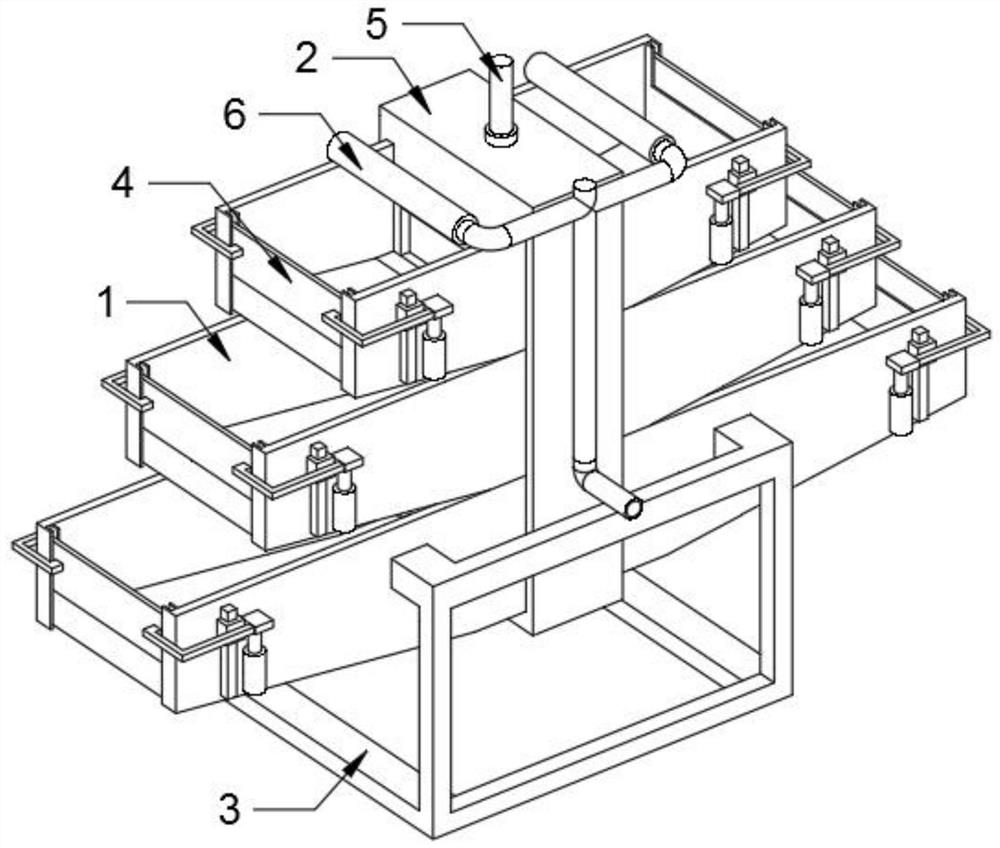

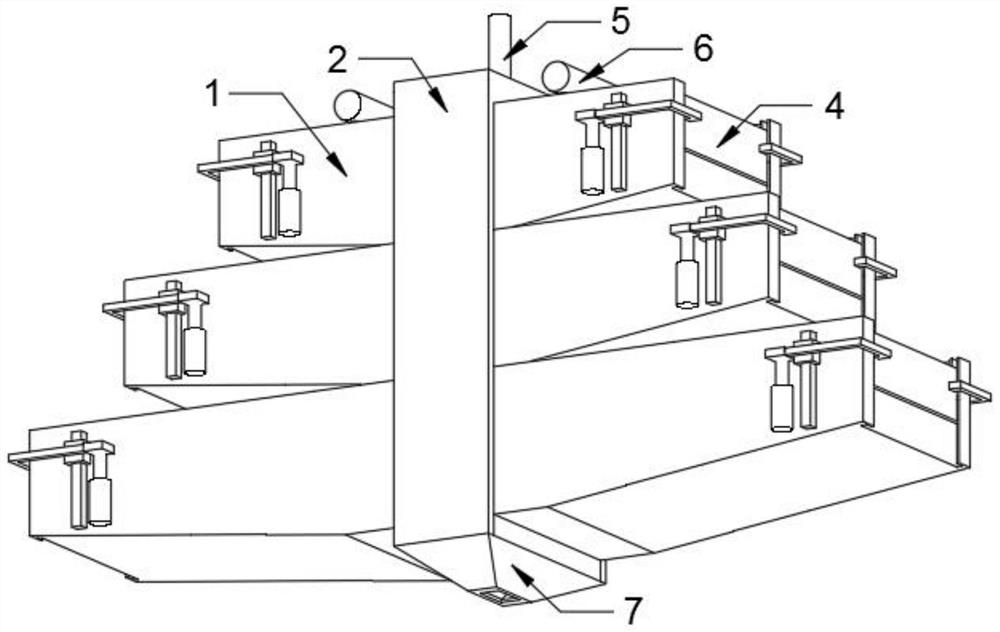

Precipitated sludge concentration device and concentration method for epoxy resin wastewater treatment

PendingCN113996091ALarge amount of single processingReduce space consumptionSettling tanks feed/dischargeSedimentation settling tanksEpoxySludge

The invention relates to the field of epoxy resin wastewater treatment, in particular to a precipitated sludge concentration device and concentration method for epoxy resin wastewater treatment. The precipitated sludge concentration device for epoxy resin wastewater treatment comprises a base shell, a plurality of pool bodies are symmetrically arranged on the two sides of the base shell in a stacked mode, the ends, close to the base shell, of the pool bodies are flush, and the other end of each of the pool bodies is sequentially lengthened outwards from top to bottom. The two stacked position adjusting mechanisms are adopted, wastewater is guided from top to bottom to be concentrated and precipitated, the single-time treatment capacity is large, the occupied space is small, the cost input is reduced, meanwhile, the base shell arranged in the middle is matched with the pollution discharge mechanism, concentrated precipitates can be synchronously discharged, and the treatment difficulty is simplified.

Owner:黄山五环科技有限公司

Multi-element crystal purification device and method

PendingCN113957523AAvoid decompositionReduce pressure difference between inside and outsidePolycrystalline material growthSingle crystal growth detailsCrucibleZone melting

The invention discloses a multi-element crystal purification device and method. The purification device comprises a furnace body, wherein a zone melting device and a purification ampoule are arranged in the furnace body; the furnace body consists of an inner-layer metal furnace chamber, an outer-layer heating device, an air pressure control device and a cooling device; and the zone melting device comprises an ampoule support, a resistance heating ring and a transmission device. The transmission device is composed of a guide rail, a lead screw, a rack sliding block and a reversing gear. The purification ampoule comprises a protection container, a purification container and a crucible; and the crucible comprises a purification crucible and a pressure control crucible. An outer-layer heating device is used for assisting, so that the pipe wall temperature can be maintained, the steam pressure in the pipe can be maintained, and crystal decomposition is inhibited; and a controllable pressurizing device is used for assisting, so that the internal and external pressure difference of the purification container is reduced, the container is kept stable, and the explosion risk is reduced. The method can effectively solve the problem of component decomposition during the purification process of the multi-element crystal containing volatile components, ensures the stoichiometric ratio of the crystal, reduces the generation of vacancy and displacement defects in the crystal, and ensures the optical and electrical properties of the crystal.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

Multifunctional self-cleaning pipetting device and application method thereof

PendingCN110404597AAvoid cloggingAchieve transferHollow article cleaningBurettes/pipettesViscous liquidPeristaltic pump

The invention discloses a multifunctional self-cleaning pipetting device which comprises a liquid inlet pipeline, a liquid storage bin, a pipette, an adapter substitute, a peristaltic pump and a pumppipe. The bottom of the liquid storage bin is connected with the pipette; the top of the liquid storage bin is connected with the bottom of the adapter substitute, a spraying sprinkler is arranged inthe liquid storage bin, and the liquid inlet pipeline penetrates through the adapter substitute and then is connected to the top of the spraying sprinkler; the two ends of the pump pipe are respectively connected with the top of the adapter substitute and the peristaltic pump, and a clamping piece is inserted to the end, close to the liquid storage bin, of the pipette. In addition, the invention also discloses an application method of the multifunctional self-cleaning pipetting device. According to the multifunctional self-cleaning pipetting device, the peristaltic pump can be effectively prevented from being blocked, and liquid including suspension liquid, viscous liquid and clear liquid can be transferred, stored and discharged; automatic cleaning can be realized, the service life can beprolonged, and the cost can be reduced; the one-time treatment capacity is large, 150 ml of liquid can be transferred, and the device is simple in structure and convenient to use.

Owner:WUXI APPTEC (TIANJIN) CO LTD

A kind of preparation method of hydrophobic modified diamond abrasive

ActiveCN110713820BSolve reunionReduce consumptionOther chemical processesCentrifugationPerchloric acid

The invention discloses a preparation method of a hydrophobic modified diamond abrasive. The method comprises the following steps: carrying out mixed acid treatment on a diamond raw material by sulfuric acid, nitric acid and perchloric acid according to a certain ratio, so that the surface of the diamond raw material has more -COOH groups; washing a diamond grinding material with water until the pH value of the supernatant is 5-7 by adopting a natural sedimentation or centrifugation method, and drying to obtain an agglomeration-free loose diamond grinding material; adding diamond powder to betreated into a high-speed mixer, spraying a hydrolyzed silane coupling agent, reacting carboxyl on the surface of diamond with the silane coupling agent at 80 DEG C for 3-5 minutes, and drying residual moisture to obtain the hydrophobic diamond powder. According to the preparation method, the mixed acid treatment is adopted so that the surface of the diamond is provided with more -COOH groups, andthe reaction capacity of the surface of the diamond and the silane coupling agent is improved; the method has the advantages of large single treatment capacity, short reaction time, simple operationprocess, low solvent consumption, energy saving and environmental protection.

Owner:HENAN UNION ABRASIVES

A method for preparing graphene microchips and graphene microchips by setting a rotating screw in a vibrating mill

The invention provides a method for manufacturing graphene nanoplatelets by arranging a rotary screw rod in a vibrating mill and the graphene nanoplatelet. A graphene raw material and dry ice are added into a milling barrel of the vertical vibrating mill with the screw rod, and the graphene raw material can be cut into the graphene nanoplatelet with complete crystal lattices under the synergistic effect of vibration of the vibrating mill, shearing of the screw rod, and gas. Due to the fact that no grinding medium exists in the vibrating mill, the situation that the crystalline structure of graphite is damaged due to repeated grinding on the graphite is avoided, and the graphene nanoplatelet with the complete crystal lattices can be obtained. Meanwhile, the preparation process is simple, the processing capacity each time is high, and the graphene nanoplatelet can be prepared efficiently.

Owner:广西鑫锋电源科技有限公司

Purification processing method for superhard grinding medium

ActiveCN101463196BLarge amount of single processingAdapt to large-scale industrial productionInorganic pigment treatmentElectricityBoiling process

The present invention discloses a method for purifying and processing ultrahard abrasive material, which comprises the steps: (1) according to the ingredients of the used catalyst, electrolytes that are matched with ferrum group, nickel group and cobalt group are respectively prepared; metal catalyst is separated out from an anode plate by utilizing an electrochemical method; (2) hexagonal boron nitride and cubic boron nitride are separated from each other; (3) in the subsequent acid boiling process, acid is dripped at the speed of 60-80 drops / min; (4) the mixture is heated to 200-300 DEG C and evenly stirred in a vessel. By adopting the technical proposal, the method has the advantages that handling capacity is large for a single time and can reach 0.35-0.4 million carats / kettle; the acid consumption and the electricity consumption can be greatly reduced, the cost is saved, and the pollution is lowered; by utilizing the electrochemical method, the metal catalyst can be easily recovered, the cost can be saved, and the pollution can be reduced; the process flow is shortened, the efficiency is improved, and the potential safety hazard is reduced.

Owner:HENAN FULAIGE ULTRAHARD MATERIAL +1

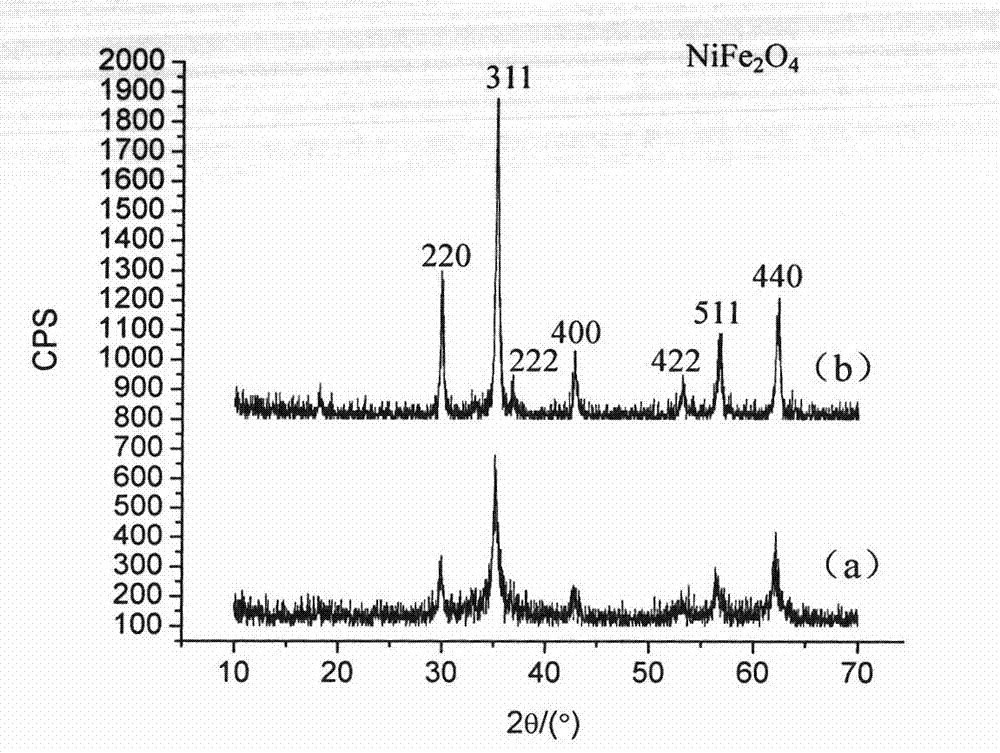

Method for preparing MxR1-xFe2O4 nanometer powder quickly

InactiveCN102173461BAvoid experimental errorEasy to operateIron oxides/hydroxidesNanotechnologyMass ratioSlurry

The invention provides a method for preparing MxR1-xFe2O4 nanometer powder quickly, which is characterized by comprising the following steps of: (1) mixing ferrous sulfate heptahydrate and one or more of crystal water-containing metal sulfates according to a molar ratio of M<2+> to R<2+> to Fe<3+> of x:(1-x):2 in a chemical structural formula MxR1-xFe2O4, and putting the mixture in a planet mill,and mixing and grinding for 3 to 5 minutes, wherein x is equal to 0.5 to 1; (2) adding a NaOH solid according to a molar ratio of Fe<2+> to OH<-> of 1:3, performing dry grinding by using the planet mill at two stages, wherein the dry grinding is performed for 8 to 10 minutes at the first stage, and is performed for 5 to 10 minutes at the second stage; and (3) adding deionized water, so that the mass ratio concentration of slurry is between 40 and 50 percent, performing wet grinding by using the planet mill for 5 to 10 minutes, and performing centrifugal separation, washing and drying sequentially to obtain the MxR1-xFe2O4 nanometer powder. In the method, the MxR1-xFe2O4 nanometer powder with an excellent crystal structure and high purity can be synthesized directly without calcining, so the method is high in operability and repeatability, the phenomenon of unstable hand lapping process of mortars in the conventional low-temperature solid-phase reaction method is prevented, energy consumption is reduced, and the method is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

Efficient grain wind power impurity removing device

ActiveCN107694929AImprove efficiencyLarge amount of single processingGas current separationEngineeringImpurity

The invention discloses an efficient grain wind power impurity removing device. The efficient grain wind power impurity removing device comprises a distributing vehicle, a distributing vehicle truss,a shell, impurity removing barrels and a supporting frame; a platen is fixedly installed at the top of the supporting frame and is fixedly provided with a cylindrical shell, the impurity removing barrels which are continuously arranged in a linear manner are arranged inside the shell, a discharging hopper is fixedly connected to the bottoms of the impurity removing barrels and extends out from thelower surface of the platen, and a material collecting hopper is installed at the position, corresponding to the discharging hopper, of the supporting frame; and a draught fan is further installed onthe platen, an air pipe is installed at the air outlet pipe of the draught fan, the air pipe is connected with multiple air inlet branches, the air inlet branches penetrate the shell and are connected with an air box on the outer side of the impurity removing barrels, and the air box is provided with an air inlet flange used for being connected with the air inlet branches. The efficient grain wind power impurity removing device has the beneficial effects that grain is evenly distributed into the impurity removing barrels through the distributing vehicle, impurity removing operation is carriedout through the multiple impurity removing barrels, efficiency is high, and the one-time processing amount is large.

Owner:双峰县富强机械科技有限公司

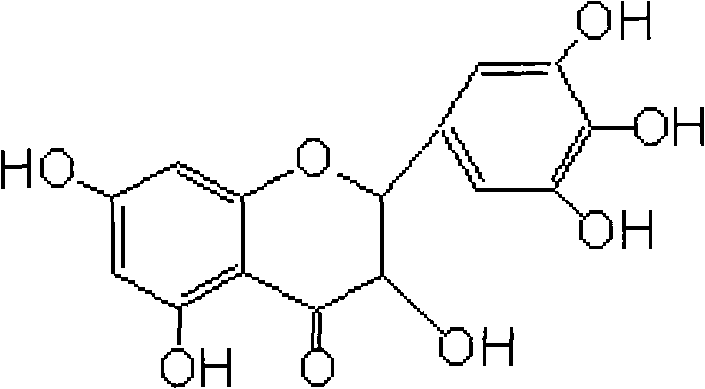

Method for purifying dihydromyricetin

The invention discloses a method for purifying dihydromyricetin, which comprises the following steps of: (1) dissolving coarse dihydromyricetin in a certain amount of solvent, and blending into a paste; (2) uniformly mixing the paste and a certain amount of adsorbent, and drying at the temperature of between 45 and 75 DEG C for 0.25 to 1 hour; (3) placing the mixture in a certain amount of water,filtering while hot, and standing the filter liquor over night; (4) filtering and drying to obtain dihydromyricetin crystal; and (5) repeating the operation once according to the steps (1) to (4) on raw materials with the coarse product content of less than 50 percent, wherein the solid liquid mass ratio, the adsorbent amount and the hot water amount for the second time are in the standard ratio based on the mass of the dihydromyricetin crystal, the rest indexes are invariable. The method for purifying the dihydromyricetin has the advantages of greatly reduction of the solvent consumption, nosolvent loss, no operation such as heating the dissolved coarse products, distilling and recovering the solvent and the like, simple equipment, low input, energy conservation and environmental protection, fewer steps, high single processing capacity, low cost, and easy industrialized production in rural areas and farms.

Owner:HANSHAN NORMAL UNIV

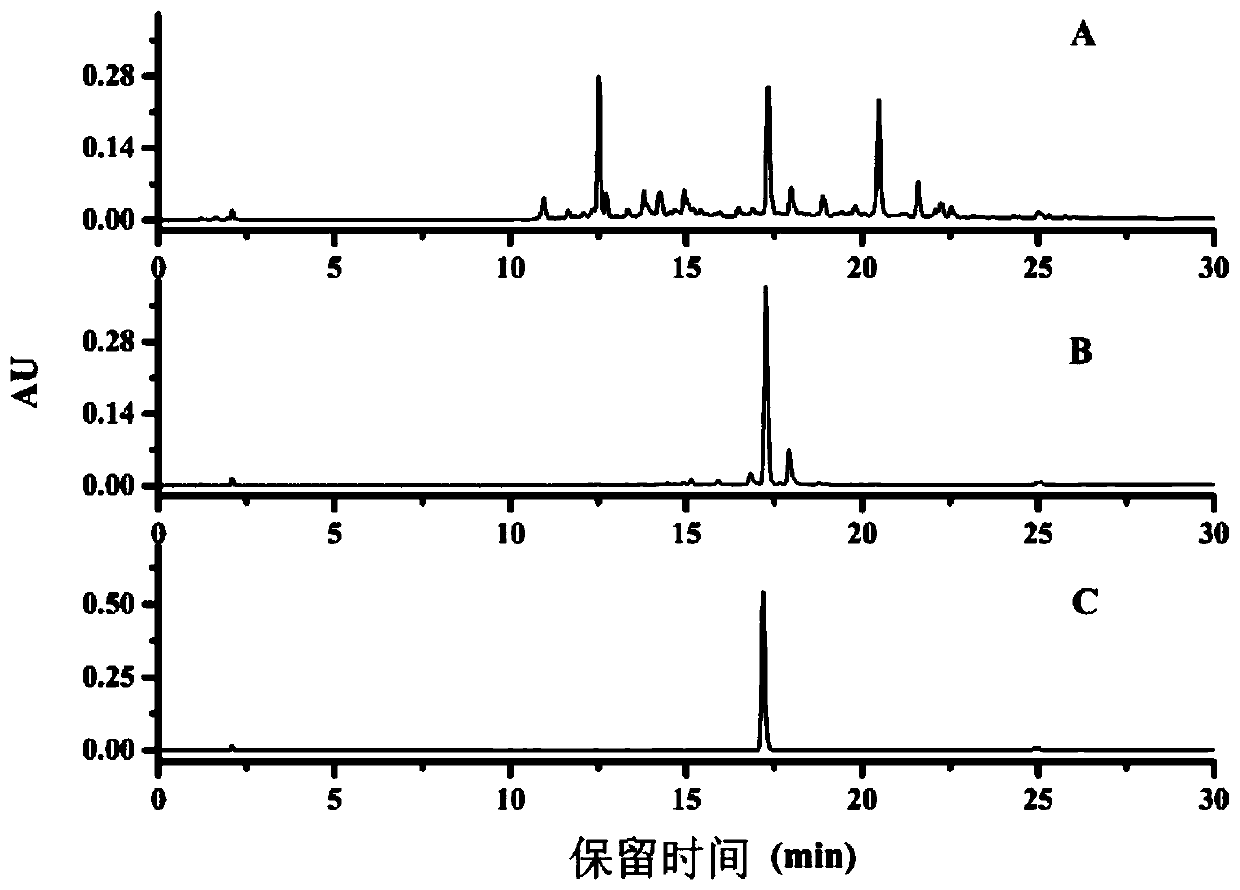

A method for efficiently separating and purifying high-purity glycyrrhizic acid

The invention provides a method for efficiently separating and purifying high-purity glycyrrhizic acid from licorice. Specifically, the glycyrrhizic acid extract obtained by concentrating the licorice extract is subjected to hydrophilic solid-phase extraction (SPE) to obtain crude glycyrrhizic acid, and the crude product is subjected to one-step reverse-phase preparation high-performance liquid chromatography to obtain pure glycyrrhizic acid. The characteristics of the present invention are: the present invention has prepared high-purity glycyrrhizic acid; after SPE treatment, the content of glycyrrhizic acid is increased from 13% in the extract to 64% in the crude product of glycyrrhizic acid, which greatly simplifies the complexity of the sample, and is The further purification of the sample creates favorable conditions; SPE has a large single-time treatment capacity and high efficiency, and is suitable for pretreatment and enrichment of target substances; reversed-phase preparative chromatography can obtain glycyrrhizic acid with a purity of 99%, which is conducive to industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A large-capacity dry food stir-frying equipment with cylinder circulation

ActiveCN105054255BThorough circulation heatingEliminate heat transfer mediumFood treatmentHelical bladeThermal insulation

The invention discloses a drum cycle large-capacity dry goods stir frying equipment, which comprises a thermal insulation cover, a threaded guide rod, a lifting arm, a sliding sleeve, a feeding motor, a main shaft, a main turning drum, a lifting drum, a thermal insulation sleeve and Heating wire, the bottom of the workbench is fixed with a feeding motor by bolts, a main shaft is installed on the feeding motor, a spiral blade is arranged at the bottom of the main shaft, and a main turning cylinder is arranged in the middle of the workbench. The lower part of the sliding sleeve is provided with a screw barrel, which is provided with an internal thread, and the internal thread is engaged with the lifting thread, and the lifting barrel is arranged inside the main turning barrel, and the outer side of the main turning barrel is set There are spiral blades, a heat preservation cover is installed on the upper part of the main turning barrel, a cover handle is arranged on the heat preservation cover, the cover handle is cone-shaped, and a steam loss hole is arranged on the heat preservation cover. The invention can thoroughly circulate and heat dry goods, save heat transfer media such as sand, is convenient for loading and unloading, is suitable for various dry goods, and has strong versatility.

Owner:湖州佳灏信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com