Multi-element crystal purification device and method

A crystal and multi-component technology, applied in the field of multi-component crystal purification devices, can solve the problems of easy decomposition of crystals, achieve the effect of ensuring crystal optics, suitable for large-scale processing, and reducing the risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

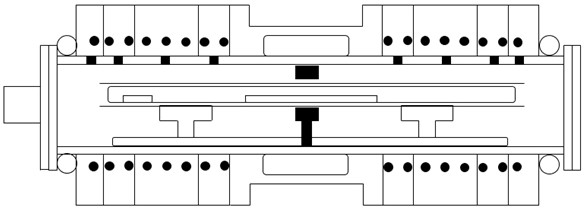

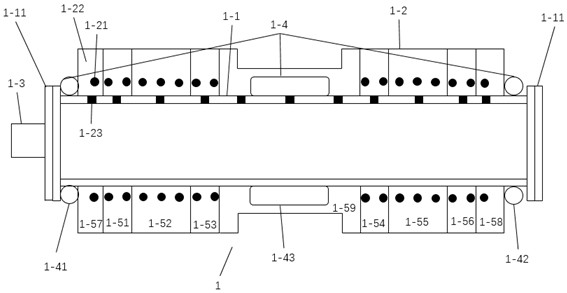

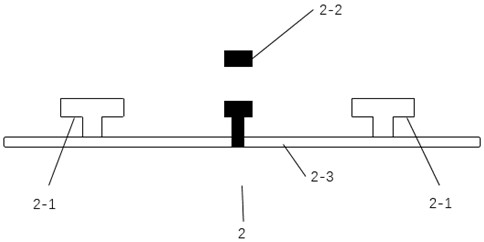

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

[0030] The purification furnace in this embodiment is designed based on the traditional multi-temperature zone synthesis furnace and the traditional zone melting furnace. Compared with the traditional multi-temperature zone synthesis furnace, the furnace body of this device adopts a pressurized and airtight design, adds a pressure control device and a zone melting device, and adds frosting to the characteristics of the transmission device and the purification process and the specific position of the purification container. deal with. Compared with the traditional zone melting device, this device changes the moving object in the zone melting process, from the "moving heating resistor" of the traditional zone melting device to "fixed heating resistor moving the purification ampoule with crystals", and at the same time increases the external heating device In order to mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com