Method for preparing MxR1-xFe2O4 nanometer powder quickly

A mxr1-xfe2o4, nano-powder technology, applied in the field of soft magnetic ferrite nano-materials, can solve the problems of increased energy consumption, poor reproducibility, and inability to industrialize production, etc., to reduce grinding time and increase single-time processing capacity , the effect of avoiding experimental error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

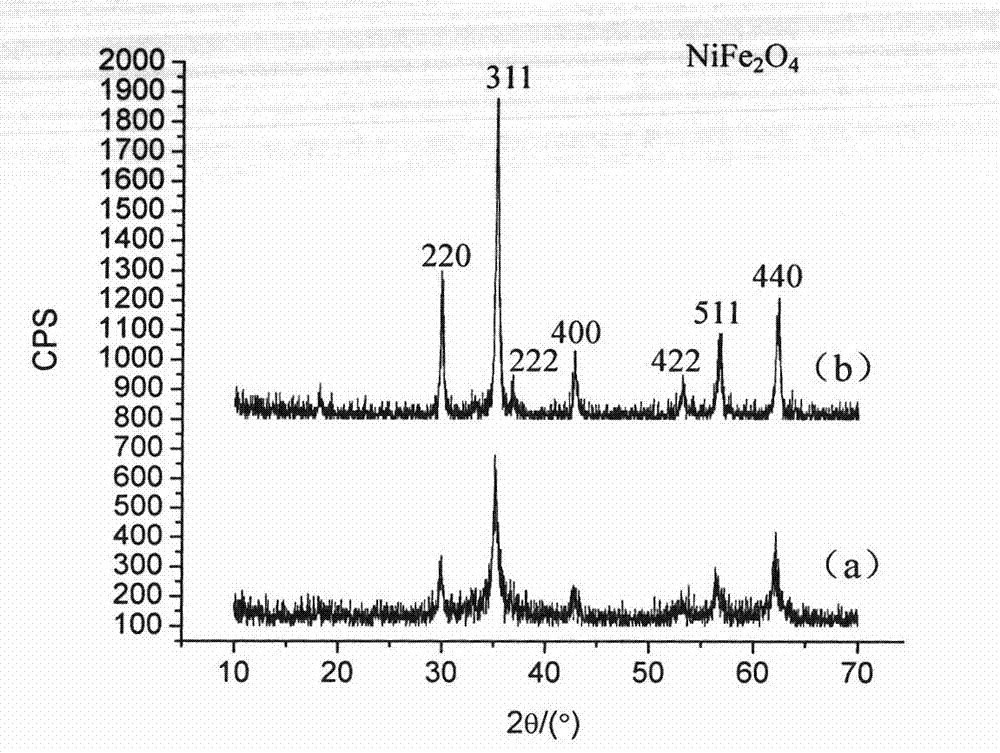

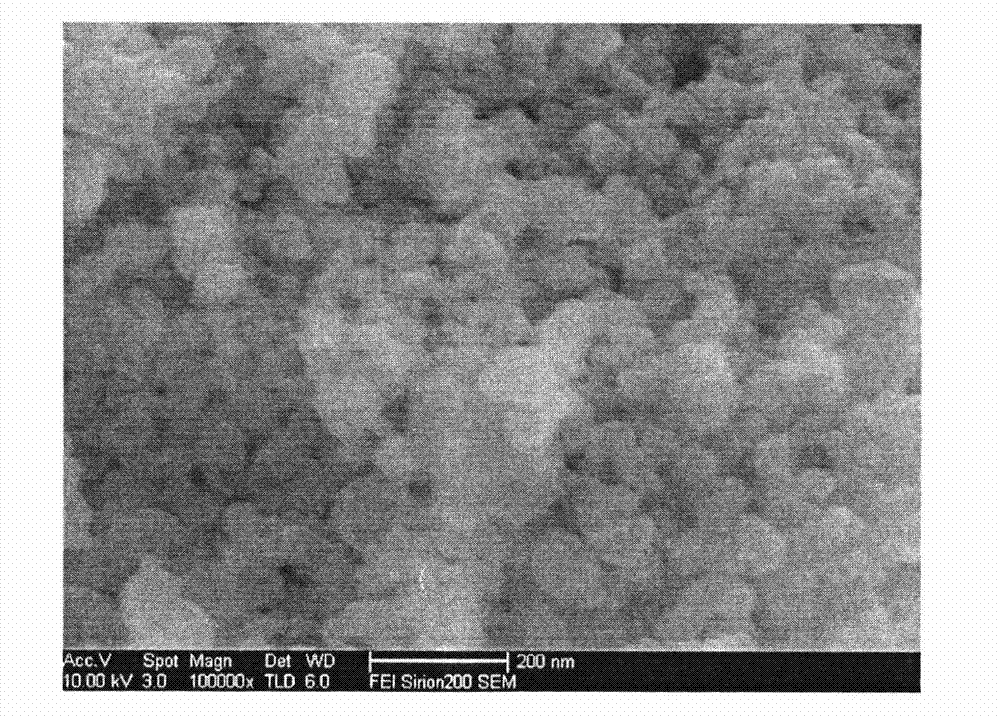

Embodiment 1

[0017] Embodiment 1: The grinding medium of the planetary mill adopts alumina balls. The diameters of the large, medium and small balls are 12mm, 10mm and 5mm respectively, and the numbers are 68, 40 and 160 respectively. The specific steps are:

[0018] (1) FeSO 4 ·7H 2 O and NiSO 4 ·6H 2 O Moore than Ni 2+ : Fe 2+ = 1:2 weighed and placed in a planetary mill, mixed and ground for 5 minutes;

[0019] (2) by Fe 2+ :OH - Add NaOH solid at a molar ratio of 1:3, and the ball-to-material ratio is 3:1. The planetary mill dry grinding process is used in two stages. The first stage is ground for 8 minutes. The grinding medium and materials in the grinding tank are taken out at the same time and dried naturally. 10 hours, then carry out the second stage of grinding for 10 minutes;

[0020] (3) Add deionized water, the mass ratio concentration of the prepared slurry is 40%, and use the planetary mill wet grinding process to grind for 5min; the slurry is centrifuged and washed w...

Embodiment 2

[0022] Embodiment 2: The grinding medium of the planetary mill adopts alumina balls, the diameters of the large balls, the middle balls and the small balls are respectively 12mm, 10mm and 5mm, and the numbers are respectively 90, 30 and 100. The specific steps are:

[0023] (1) FeSO 4 ·7H 2 O, NiSO 4 ·6H 2 O and ZnSO 4 ·7H 2 O Moore than Ni 2+ : Zn 2+ : Fe 2+ =0.5:0.5:2 Weigh and place in a planetary mill, mix and grind for 5 minutes;

[0024] (2) by Fe 2+ :OH -Add NaOH solid at a molar ratio of 1:3, and the ball-to-material ratio is 4:1. The planetary mill dry grinding process is used in two stages. The first stage is ground for 10 minutes. The grinding medium and materials in the grinding tank are taken out at the same time and dried naturally. After 10 hours, carry out the second stage of grinding for 5 minutes;

[0025] (3) Add deionized water, the mass ratio concentration of the prepared slurry is 45%, and use the planetary mill wet grinding process to grind fo...

Embodiment 3

[0027] Embodiment 3: The grinding medium of the planetary mill adopts alumina balls. The diameters of the large, medium and small balls are 12mm, 10mm and 5mm respectively, and the numbers are 70, 60 and 120 respectively. The specific steps are:

[0028] (1) FeSO 4 ·7H 2 O, NiSO 4 ·6H 2 O and MnSO 4 ·H 2 O Moore than Ni 2+ :Mn 2+ : Fe 3+ =0.95:0.05:2 Weigh and place in a planetary mill for mixing and grinding for 3 minutes;

[0029] (2) by Fe 2+ :OH - Add NaOH solid at a molar ratio of 1:3, and the ball-to-material ratio is 3:1. The planetary mill dry grinding process is used in two stages. The first stage is ground for 8 minutes. The grinding medium and materials in the grinding tank are taken out at the same time and dried naturally. 10 hours, then carry out the second stage of grinding for 10 minutes;

[0030] (3) Add deionized water, the mass ratio concentration of the prepared slurry is 45%, and use the planetary mill wet grinding process to grind for 8min; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com