Method for degrading lindanee in different types of soil by using additive in cooperation with mechanochemical method

A technology of synergistic machinery and additives, applied in the field of lindane-contaminated soil remediation, can solve problems such as not much, achieve the effects of less dosage, prolonging the ball milling time, and fast degradation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

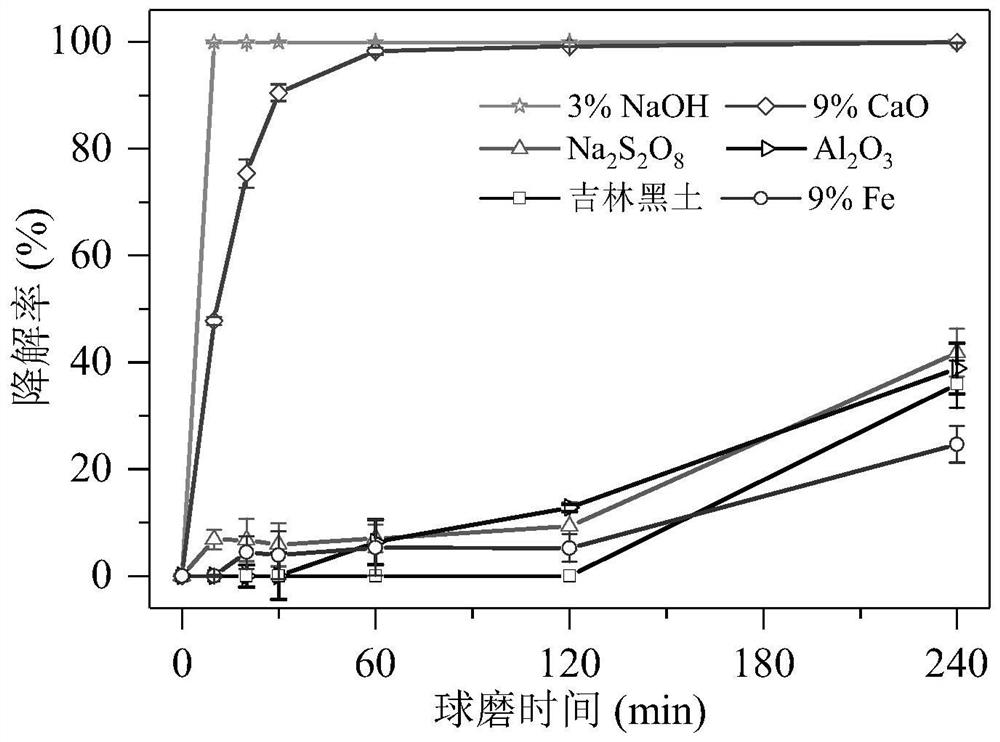

[0037] Degradation effect of different additives and mechanochemical method on lindane in Jilin black soil

[0038] The selected additives include NaOH, CaO, Al 2 o 3 、Na 2 S 2 o 8 and Fe powder. Accurately weigh 30.0g of lindane polluted Jilin black soil (lindane concentration in the soil is about 100mg / kg), 0.900 / 2.700g (material ratio is 3% / 9%) additive, 309.0 / 327.0g grinding balls are added to the ball milling tank, set In the ball mill, set the speed of the ball mill tank to 500r / min, run in a horizontal planetary mode, change the direction of rotation after every 10 minutes of running for 1 minute, and take 0.05g of soil after ball milling for 10, 20, 30, 60, 120 and 240 minutes respectively , for the determination of lindane content in soil.

[0039] figure 1In this paper, the effects of different additives on the degradation of lindane in Jilin black soil were compared. The experimental results showed that when 3% NaOH was added, the degradation rate of lindane ...

Embodiment 2

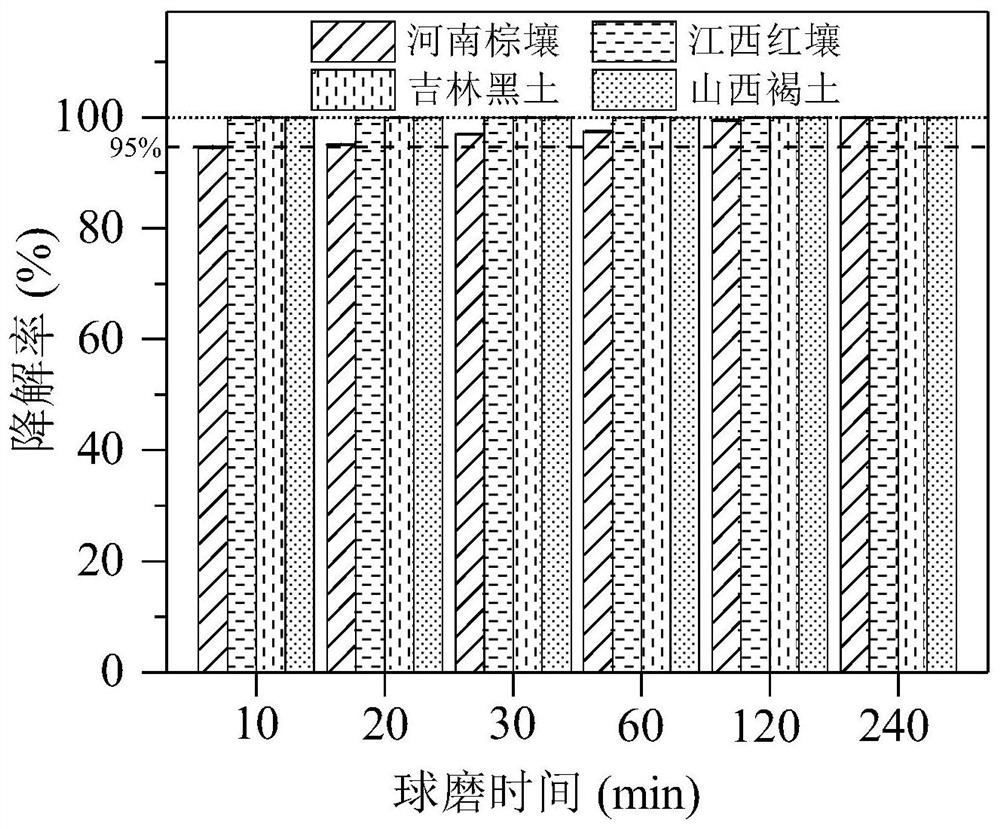

[0041] Degradation Effect of Lindane in Four Kinds of Soils Using NaOH as Additive Synergistically with Mechanochemical Method

[0042] Accurately weigh 30.0 g of Henan brown soil, Jiangxi red soil, Jilin black soil, Shanxi cinnamon soil, and Lindane-contaminated Shanxi cinnamon soil with a concentration of about 500 mg / kg in a ball mill, and then add Put 0.900g of NaOH and 309.0g of balls in the ball mill, set the speed of the ball mill to 500r / min, run in a horizontal planetary mode, change the direction and rotate after every 10 minutes of running, and take 10, 20, 30, 0.05g of soil after 60, 120 and 240min is used to determine the lindane content in the soil.

[0043] Such as figure 2 It is shown that using NaOH as an additive can quickly realize the efficient degradation of lindane in various soils. After ball milling for 10 minutes, the degradation rate of lindane in Henan brown soil reached 94.6%, and the content of lindane in brown soil decreased from the original ab...

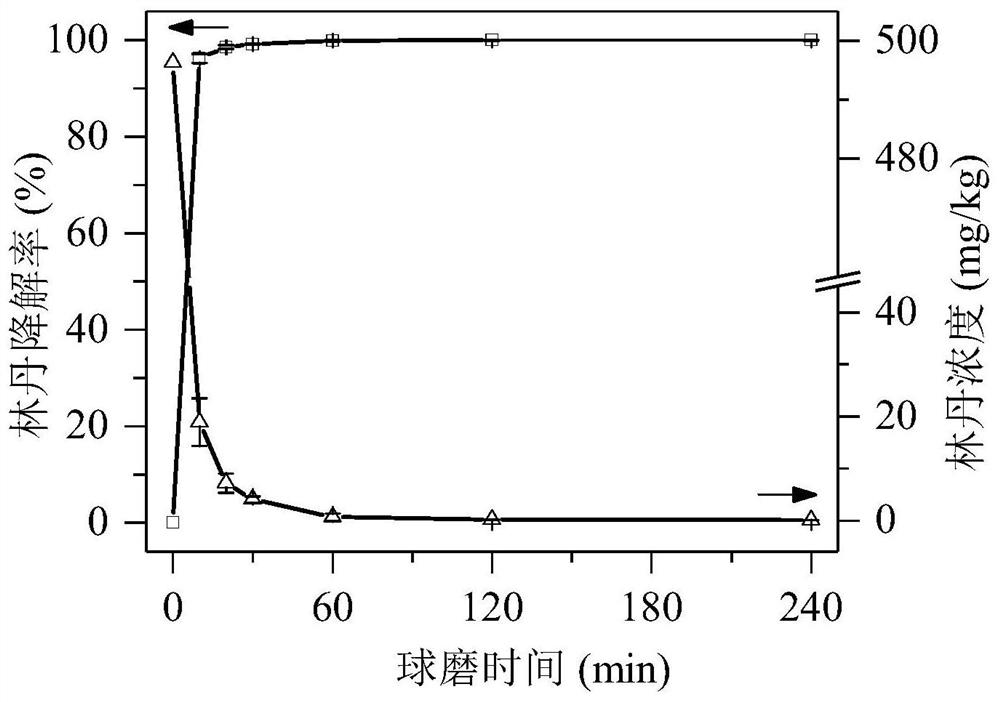

Embodiment 3

[0046] Degradation effect of lindane in four kinds of soils with CaO as additive and mechanochemical method

[0047] Accurately weigh 30.0g of lindane-contaminated soil with a concentration of about 100mg / kg, 318.0 / 327.0g of grinding balls, and 1.800 / 2.700g of additives in a ball mill, and put them into the ball mill. Set the speed of the ball mill to 500r / min. Run in planetary mode, change direction and rotate after every 10 minutes of running, stay for 1 minute, and take 0.05 g of soil after ball milling for 10, 20, 30, 60, 120 and 240 minutes, respectively, to determine the content of lindane in the soil.

[0048] Depend on Figure 4 It can be seen that using CaO as an additive can also achieve efficient degradation of lindane in various types of soils: the degradation rate of lindane in brown soil after adding 9% CaO for 240 min after ball milling is 93.2%; adding 9% CaO after ball milling for 60 min The degradation rate of lindane in black soil reached 98.3%; for Jiangxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com