Purification method of electron mediator azure c

A technology of electronic medium and purification method, which is applied in the field of purification of electronic medium, can solve the problems of low sample loading, low HPLC purification efficiency, and high cost, and achieve the effects of improving production efficiency, large output, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

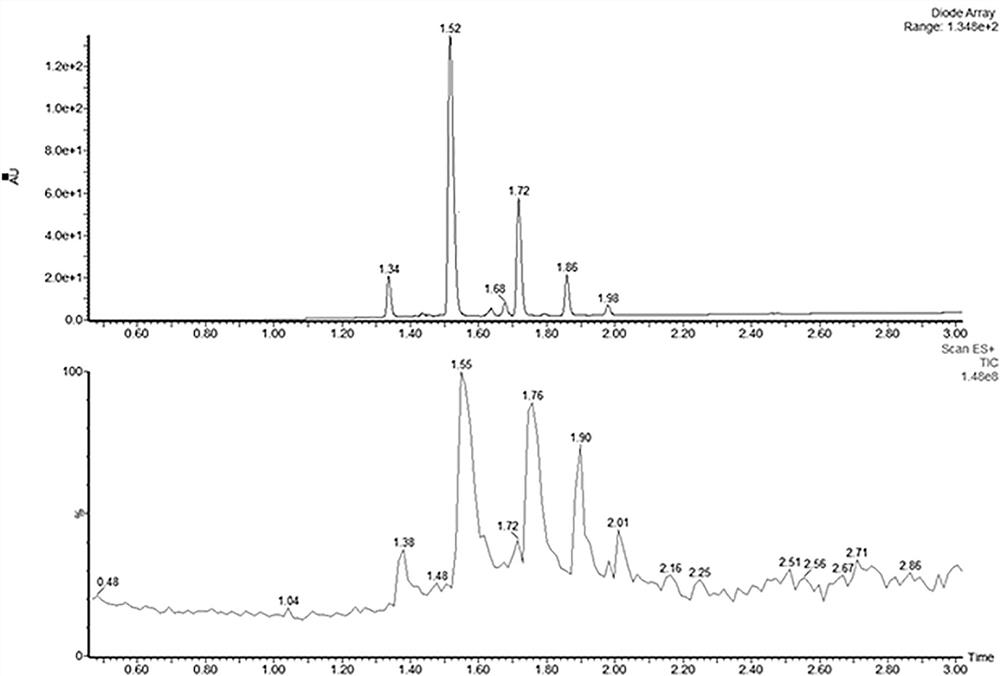

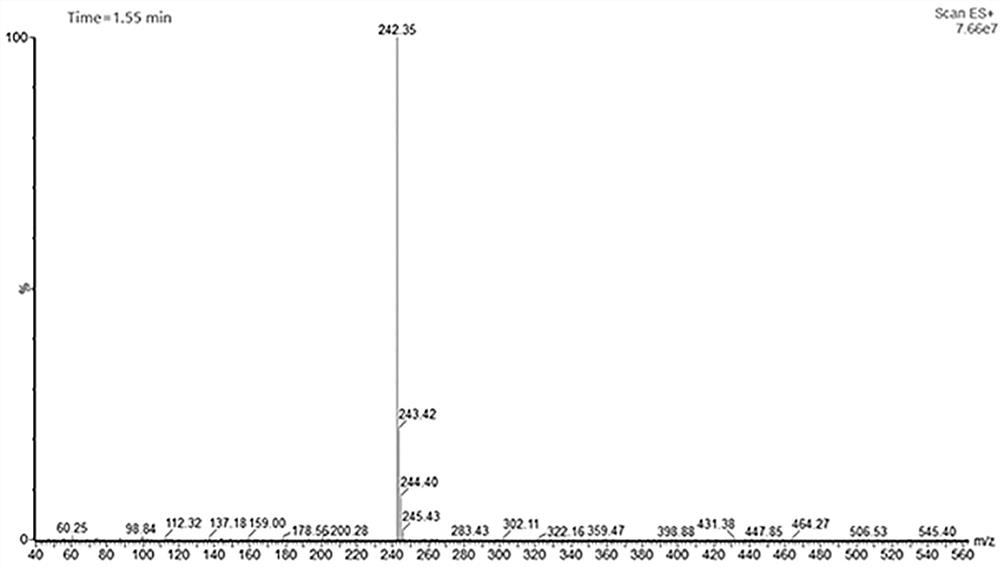

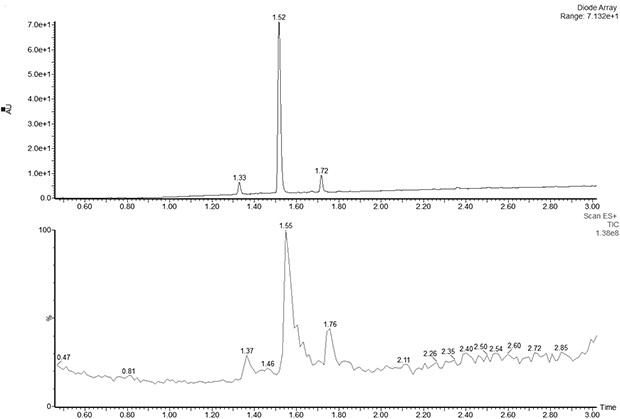

Image

Examples

Embodiment 1

[0026] Example 1 Purification of Azure C (Azure C) with Fmoc-Cl as an amino protecting reagent

[0027] Fluorene methoxycarbonyl chloride (Fmoc-Cl) as an amino protecting agent to purify azurine C.

[0028]

[0029] Weigh 15g (141.5mmol) of sodium carbonate, add 150ml of water and stir to dissolve, then add 150ml of dioxane, 10g (36mmol) of commercially available Azure C with a content of 40%, and cool to 10°C in an ice-water bath. 23.28 g (90 mmol) of fluorene methoxycarbonyl chloride was added in batches, reacted in an ice-water bath for 1 hour, and then transferred to room temperature to react for 2 hours, resulting in a viscous product. The supernatant was poured off, the viscous product was dissolved in dichloromethane, insoluble impurities were filtered off, and the filtrate was washed with water; dried over anhydrous sodium sulfate, filtered, and concentrated to obtain 3.4 g of intermediate (Fmoc) 2 -Azure C. (Fmoc) 2 -Azure C is amino-protected azure C.

[0030]...

Embodiment 2

[0031] Example 2 Commercially available Azure C was directly prepared and purified by HPLC (comparative example)

[0032] As a comparative example of the present invention, the method for directly purifying commercially available Azure C by HPLC is as follows.

[0033] Instrument: Waters Prep150 preparative liquid chromatography, chromatographic column: SunFire® Prep C18 OBD™ 5μm 19×150mm Column.

[0034] Mobile phase: acetonitrile / water (0.05% trifluoroacetic acid), acetonitrile %=15~55% (10min).

[0035] Flow rate: 20ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com