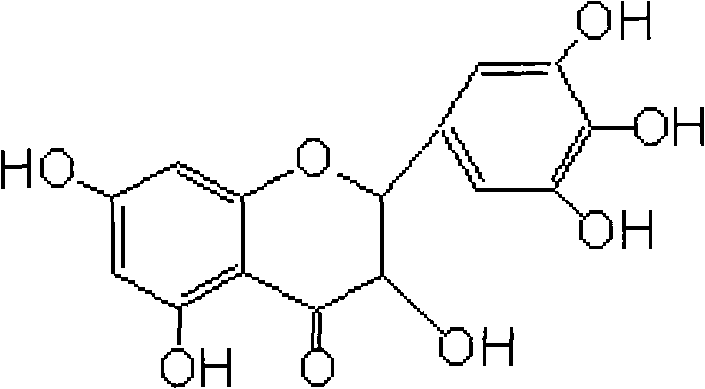

Method for purifying dihydromyricetin

A technique of dihydromyricetin and a purification method, which is applied in the field of separation of active components of natural products, can solve problems such as high equipment requirements, large solvent consumption, and low-temperature aging, and achieve simple equipment, large single-time processing capacity, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below through examples.

[0026] Weigh 10 g of dihydromyricetin crude product (48%, quantitatively analyzed by HPLC), add 20 ml of absolute ethanol, stir into a paste, add 10 g of activated carbon, and place at 60 ° C for 30 min; add 1200 ml of 90 ° C water, stir for a while After hot filtration, the filtrate was placed at room temperature overnight; after filtration and drying, dihydromyricetin crystals were obtained, weighing 4.28 g, with a purity of 83%.

[0027] The above obtained dihydromyricetin crystals are recrystallized according to the above operations. In the recrystallization, except that the addition of absolute ethanol is 8.5ml, the amount of activated carbon is 4.28g, and the amount of hot water is 513ml, the rest remain unchanged. The dihydromyricetin obtained by secondary crystallization Myricetin crystal 2.5g, purity 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com