A method for efficiently separating and purifying high-purity glycyrrhizic acid

A technology for separating and purifying glycyrrhizic acid, which is applied in chemical instruments and methods, organic chemistry, steroids, etc., can solve the problems of high-purity glycyrrhizic acid being expensive, difficult to enter the international market, and difficult to obtain high-purity, etc. To achieve green environmental protection industrial production, conducive to industrial production, the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

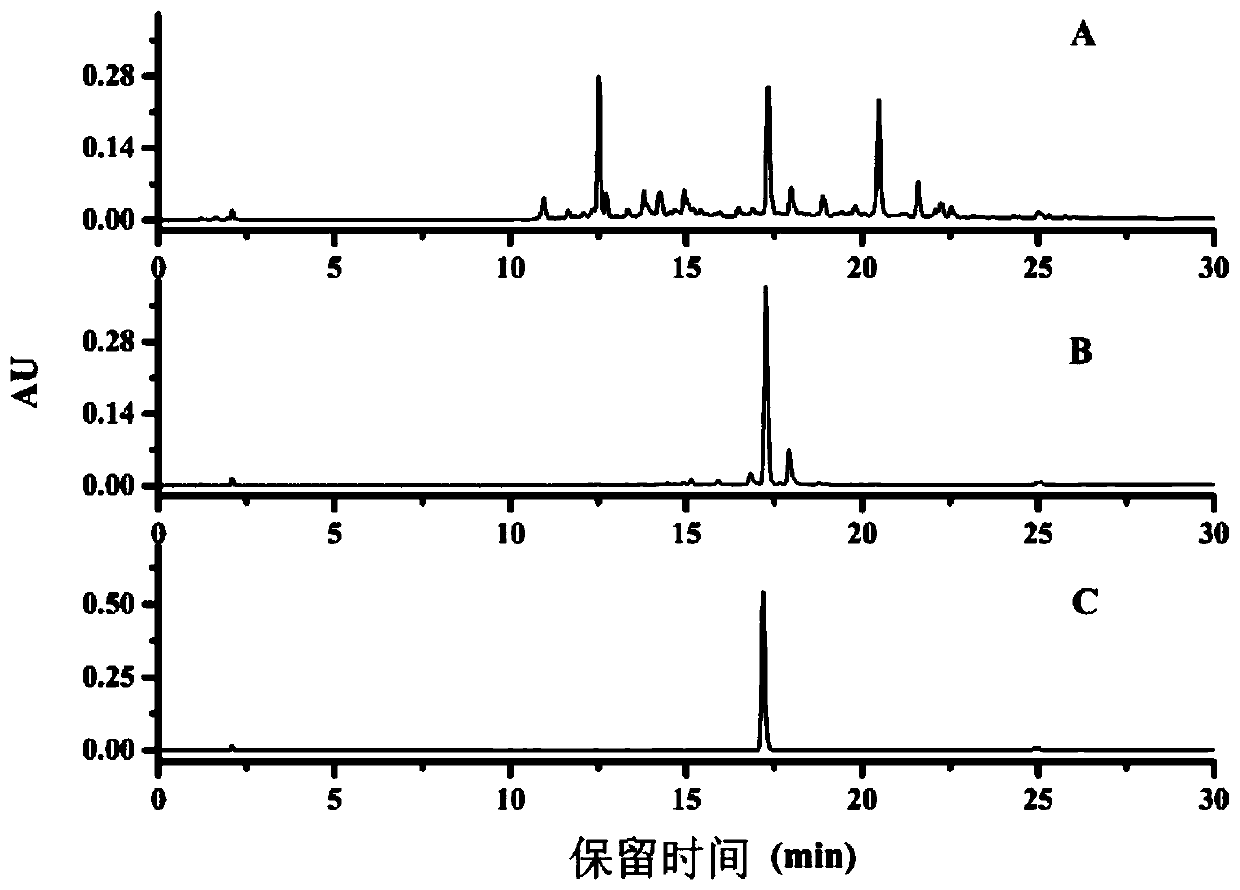

Image

Examples

Embodiment 1

[0015] 1) Preparation of glycyrrhizic acid extract: take 10 g of licorice root and crush it into a coarse powder with a particle size of 60 mesh, use 100 mL of 70% (V / V) ethanol solution for ultrasonic extraction for 3 hours, filter and concentrate until the solid content is about 100 mg / mL, Glycyrrhizic acid extract;

[0016] 2) Preparation of crude glycyrrhizic acid: the hydrophilic SPE column (filler is XAmide, filler particle size is 5 μm,

[0017] Loading capacity is 1g) After activating and equilibrating with 4 times column volume of 50% (V / V) ethanol, take 10 mL of the glycyrrhizic acid extract obtained in step (1) and load it on the above-mentioned balanced SPE column, and use 4 times column volume Rinse with 50% (V / V) ethanol solution, add formic acid to adjust the pH to 3.5 in the above activation, equilibration, sample loading and rinsing steps, and add ammonium bicarbonate, the salt concentration should be 2mM, and finally use 5 times the column volume 20% (V / V) e...

Embodiment 2

[0020] 1) Preparation of glycyrrhizic acid extract: take 1 kg of licorice root and rhizome and crush it into a coarse powder with a particle size of 120 mesh, use 10L of 60% ethanol for ultrasonic extraction for 5 hours, filter the filter residue and continue to use 10L of 60% ethanol for ultrasonic extraction for 5 hours, filter, and combine the filtrates. Concentrate to a solid content of about 150mg / mL to obtain a glycyrrhizic acid extract;

[0021] 2) Preparation of glycyrrhizic acid crude product: the hydrophilic SPE column (filler is Click XIon, filler particle size is 60 μm,

[0022] Loading capacity is 50g) with 6 times of column volume 60% (V / V) ethanol activation, balance, take the glycyrrhizic acid extract obtained in step (1) 20mL load on the SPE column of above-mentioned equilibrium, use 4 times of column volume Rinse with 50% (V / V) ethanol solution. For the above activation, equilibration, sample loading and rinsing steps, formic acid should be added to adjust th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com