Precipitated sludge concentration device and concentration method for epoxy resin wastewater treatment

A technology for wastewater treatment and sludge concentration, which is applied to the feeding/discharging device, separation method, precipitation separation, etc. of the sedimentation tank. The effect of large processing capacity, reduced cost investment and small space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

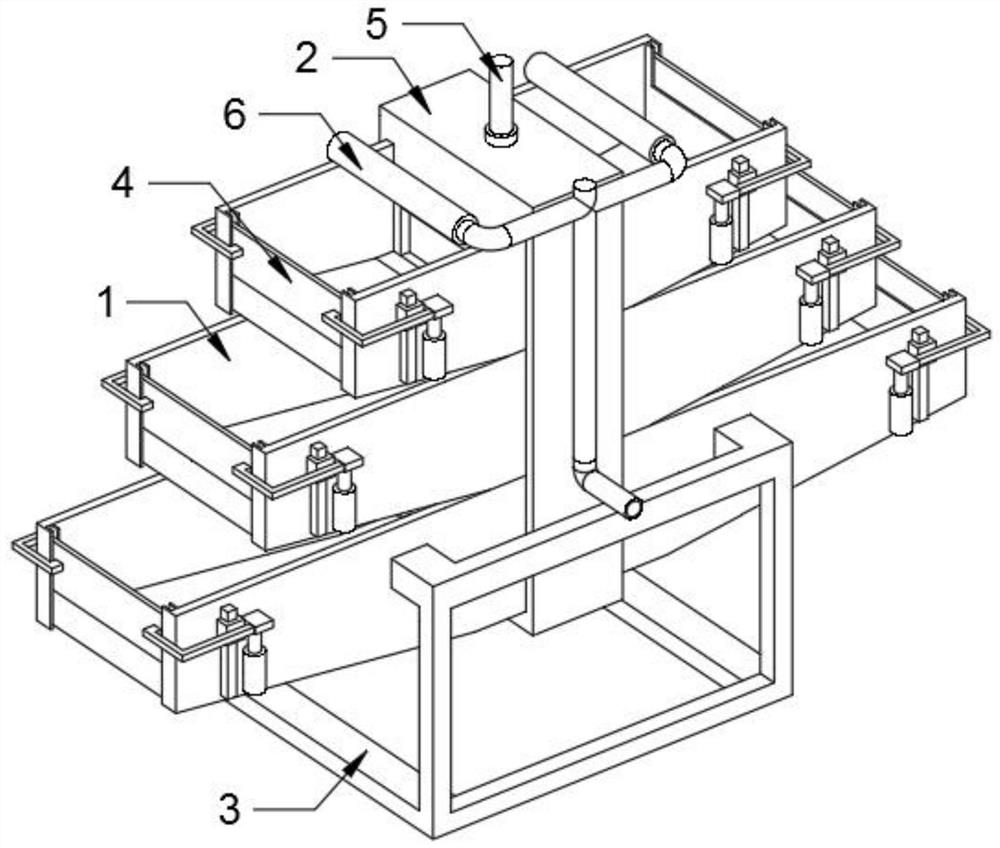

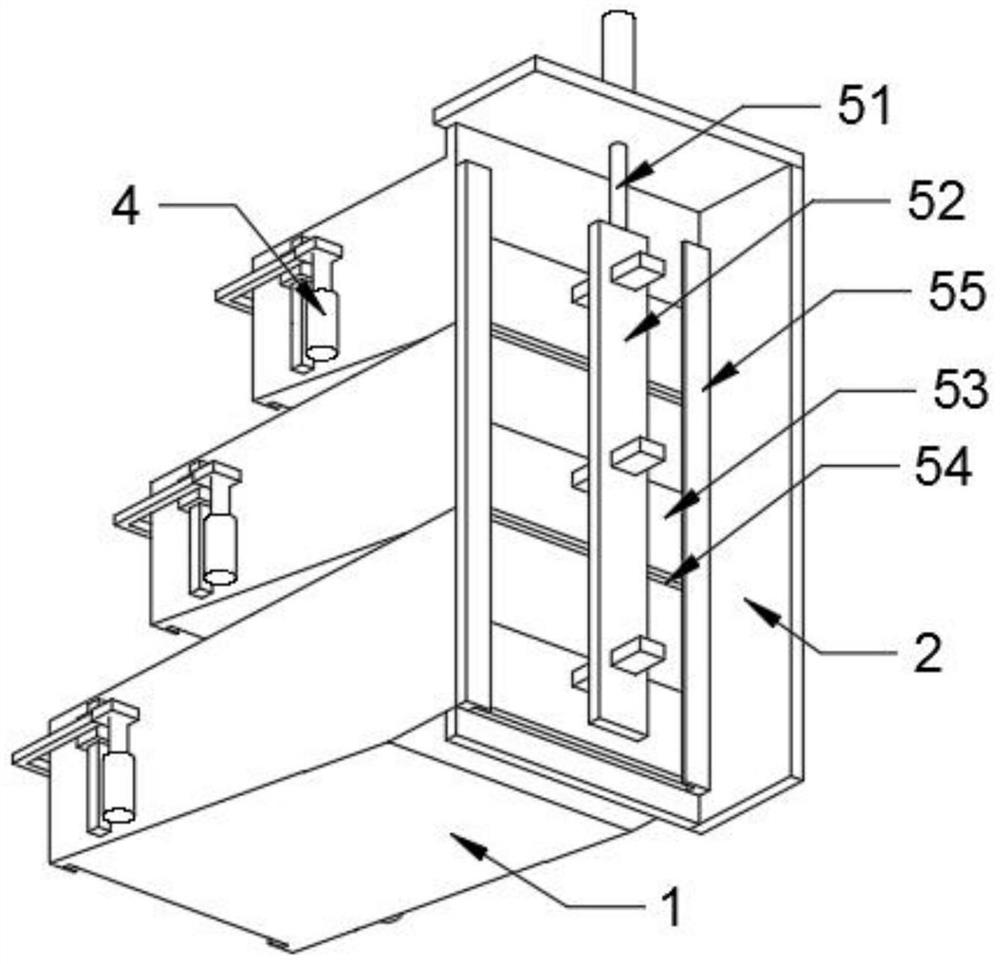

[0029] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, a sedimentation sludge thickening device for epoxy resin wastewater treatment is assembled from the following components:

[0030]

[0031]

[0032] Assembly instructions: Arrange and fix the pool body 1 on both sides with the base shell 2 as the center. Corresponding to the surface of the base shell 2, a sewage outlet 54 is opened, and the two sides of the sewage outlet 54 are symmetrically welded with guide rails 55. A sealing plate 53 is slidably arranged between the guide rails 55, and is aligned with the sewage outlet 54. The sealing plate 53 is fixedly connected with the connecting plate 52.

[0033] Working principle: When injecting waste water, connect the liquid pipe 61 with the waste water driving equipment, the waste water is introduced into the nozzle 62, and dispersed into the pool body 1 through the nozzle hole 63, and the waste water fills each pool body 1 sequentially from top to bo...

Embodiment 2

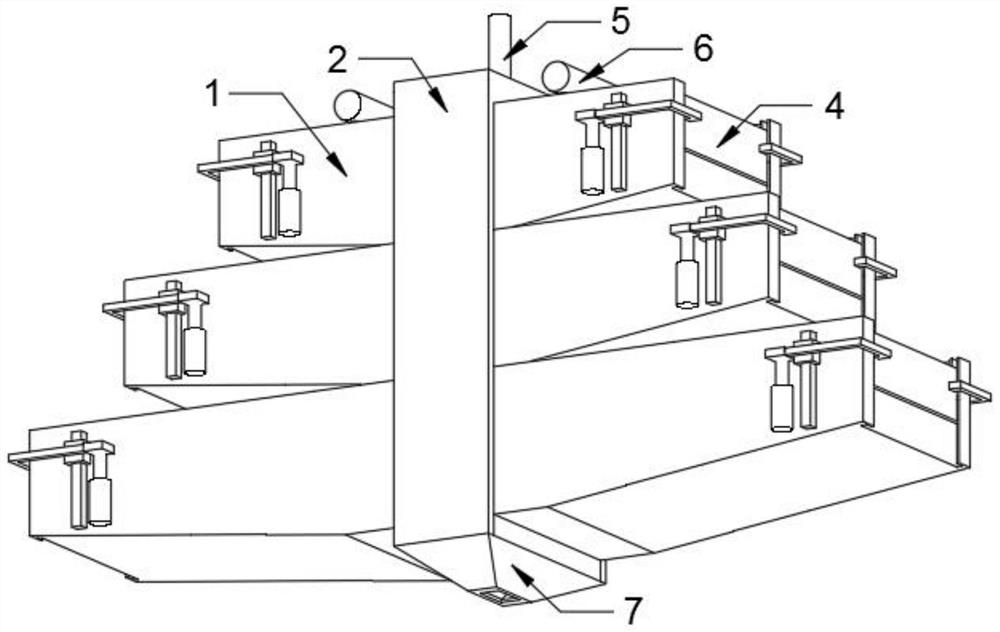

[0035] Such as figure 1 and Figure 4 As shown, a sedimentation sludge thickening device for epoxy resin wastewater treatment is assembled from the following components:

[0036]

[0037]

[0038] Assembly instructions: Arrange and fix the pool body 1 on both sides with the base shell 2 as the center. The electric push rod 43 is installed on both sides of the body 1, and the connecting frame 44 is fixed on the top, and the connecting frame 44 is connected with the water level plate 45. fixed.

[0039] Working principle: the water level plate 45 blocks the sinking tank 47, and the top of the water level plate 45 is the highest position of the liquid level. Open the electric push rod 43 to drive the connecting frame 44 to adjust the water level plate 45 to adjust the height of the liquid level in the pool body 1. The clear layer on top of the pellet was drained.

[0040] A kind of sedimentation sludge thickening method of epoxy resin wastewater treatment, concrete step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com