A flexible, fast-changing, combined injector nozzle hole precision drilling fixture

A combined and flexible technology, applied in the direction of precision positioning equipment, clamping, manufacturing tools, etc., can solve the problems of fixture management difficulties, low production efficiency, and increased difficulty of fixture management, so as to improve the level of on-site management and reduce product manufacturing costs. The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

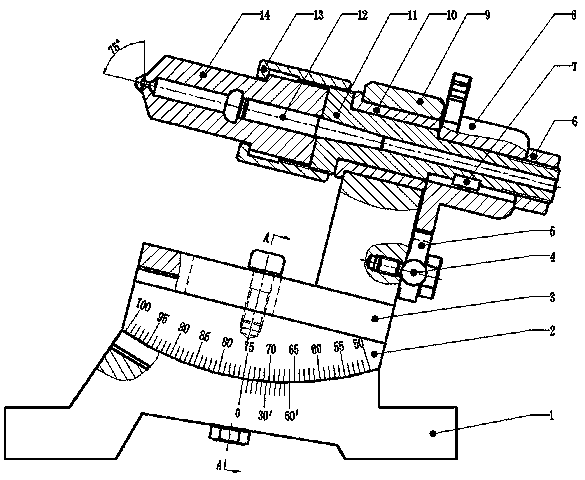

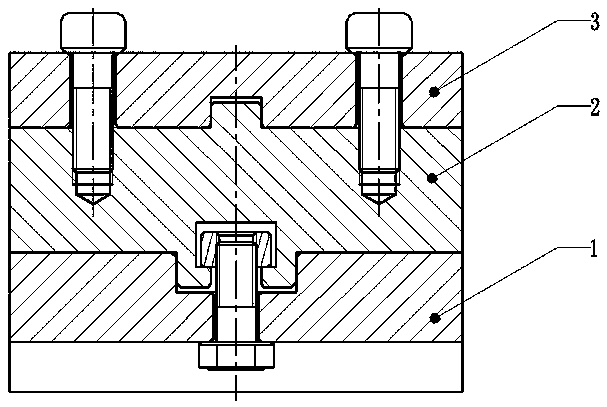

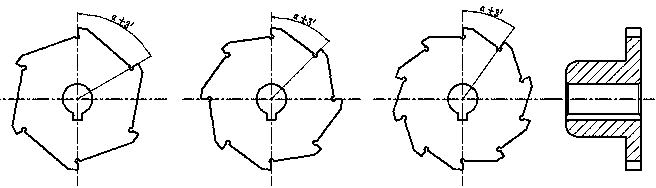

[0022] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1-5 As shown, a flexible, quick-change, combined injector nozzle hole precision drilling fixture, including a base 1, such as Figure 1-2 As shown, the angle plate 2 is connected with the base 1 through a slider, and the angle plate 2 slides circumferentially in the chute of the base 1 and is locked by bolts. Such as figure 1 As shown, the main ruler is engraved on the angle plate 2, and the auxiliary ruler is engraved on the base 1. At this time, the 0 engraved line of the auxiliary ruler is aligned with 75 of the main ruler, indicating that the angle between the center line of the nozzle hole and the axis of the needle valve body is 75°. The angle plate 2 utilizes the scale lines of the main and auxiliary scales and the precision slider structure to realize the precise adjustment of various spray hole angles. The circumferential position of the angle plate 2 can be adjusted fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com