Novel flow instrument packaging box

A flow meter and packaging box technology, applied in the field of new flow meter packaging boxes, can solve the problems of poor shock resistance of the packaging box and damage to the flow meter, and achieve the effect of good flexibility, good shock resistance and buffering effect, and avoidance of damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

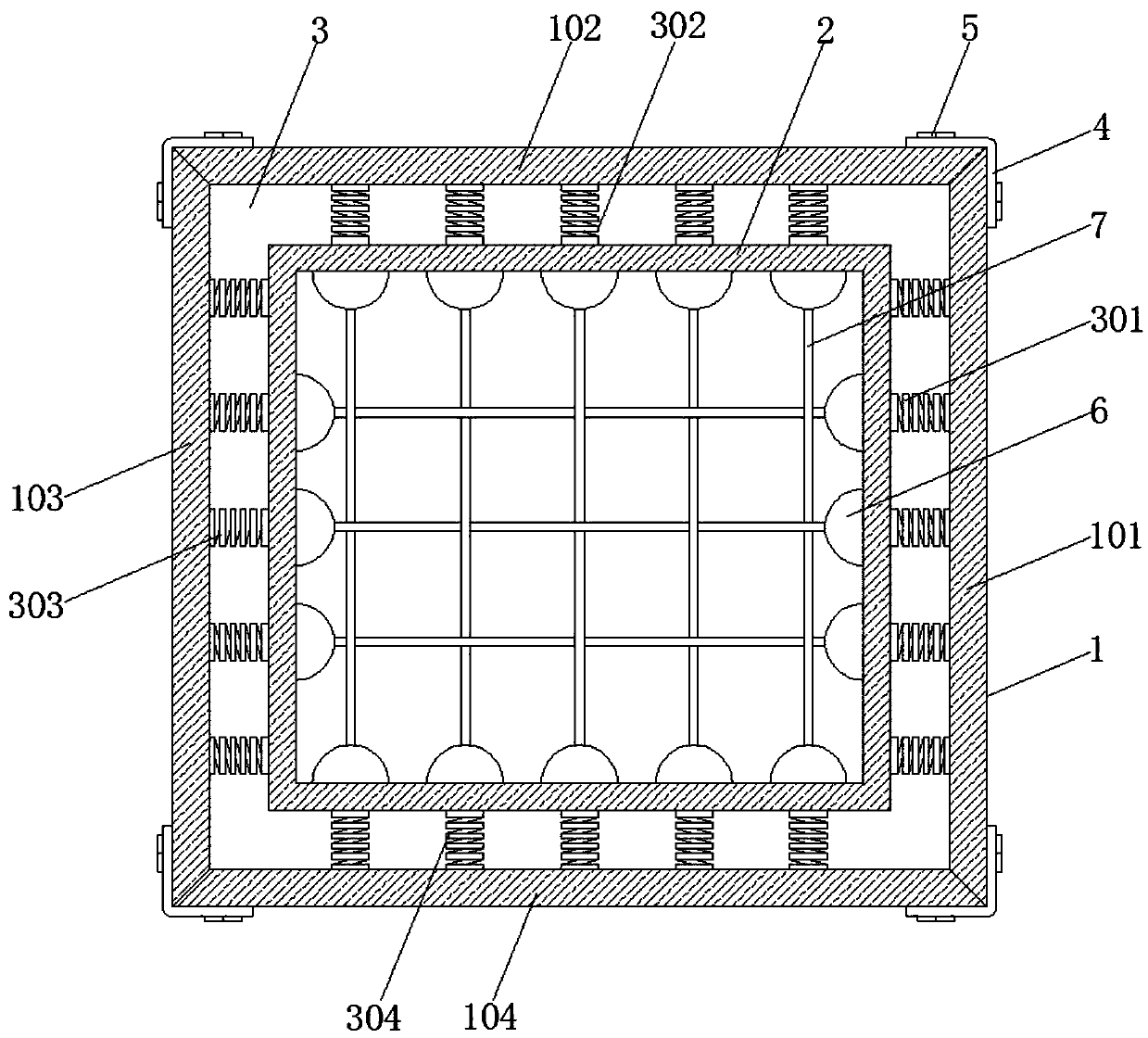

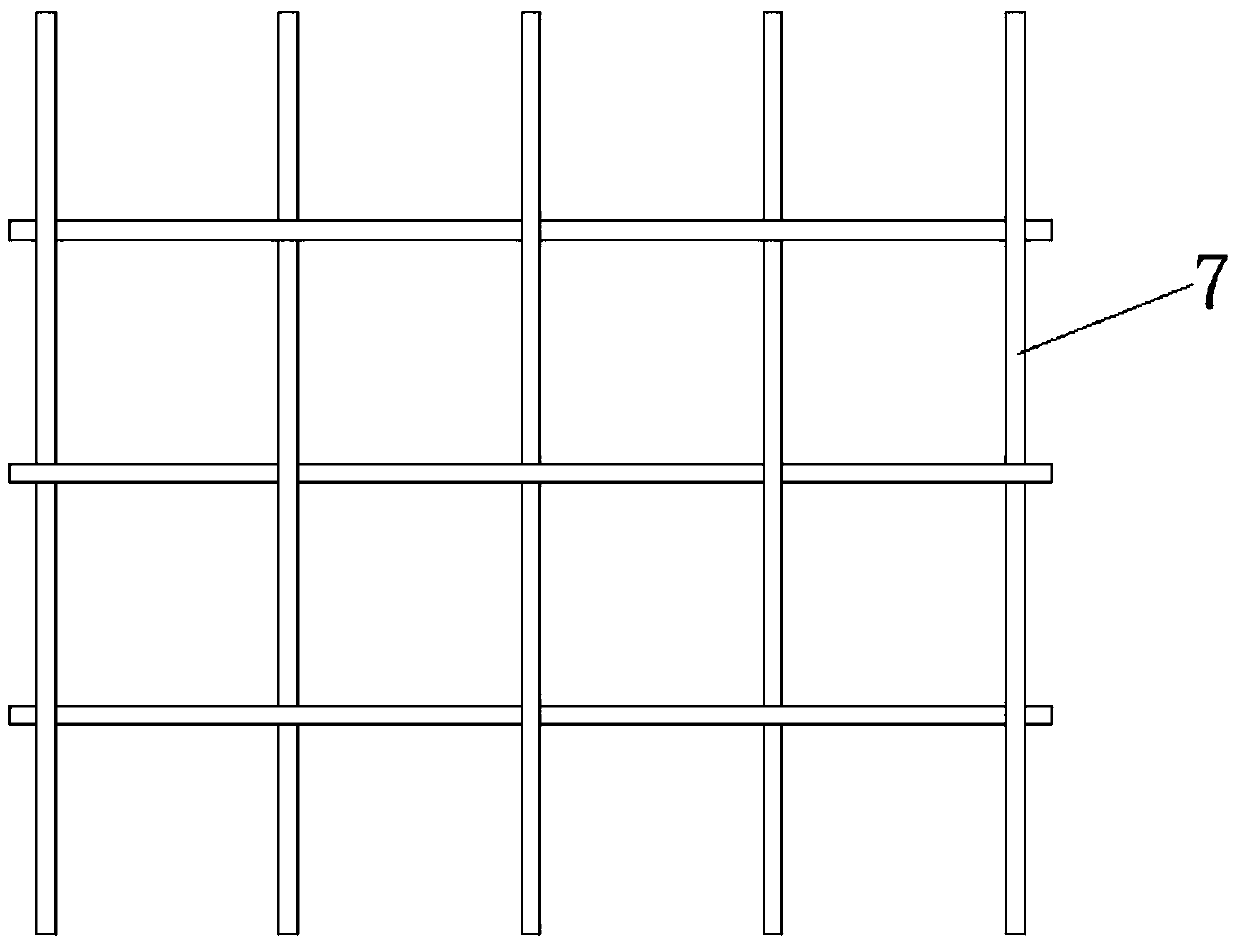

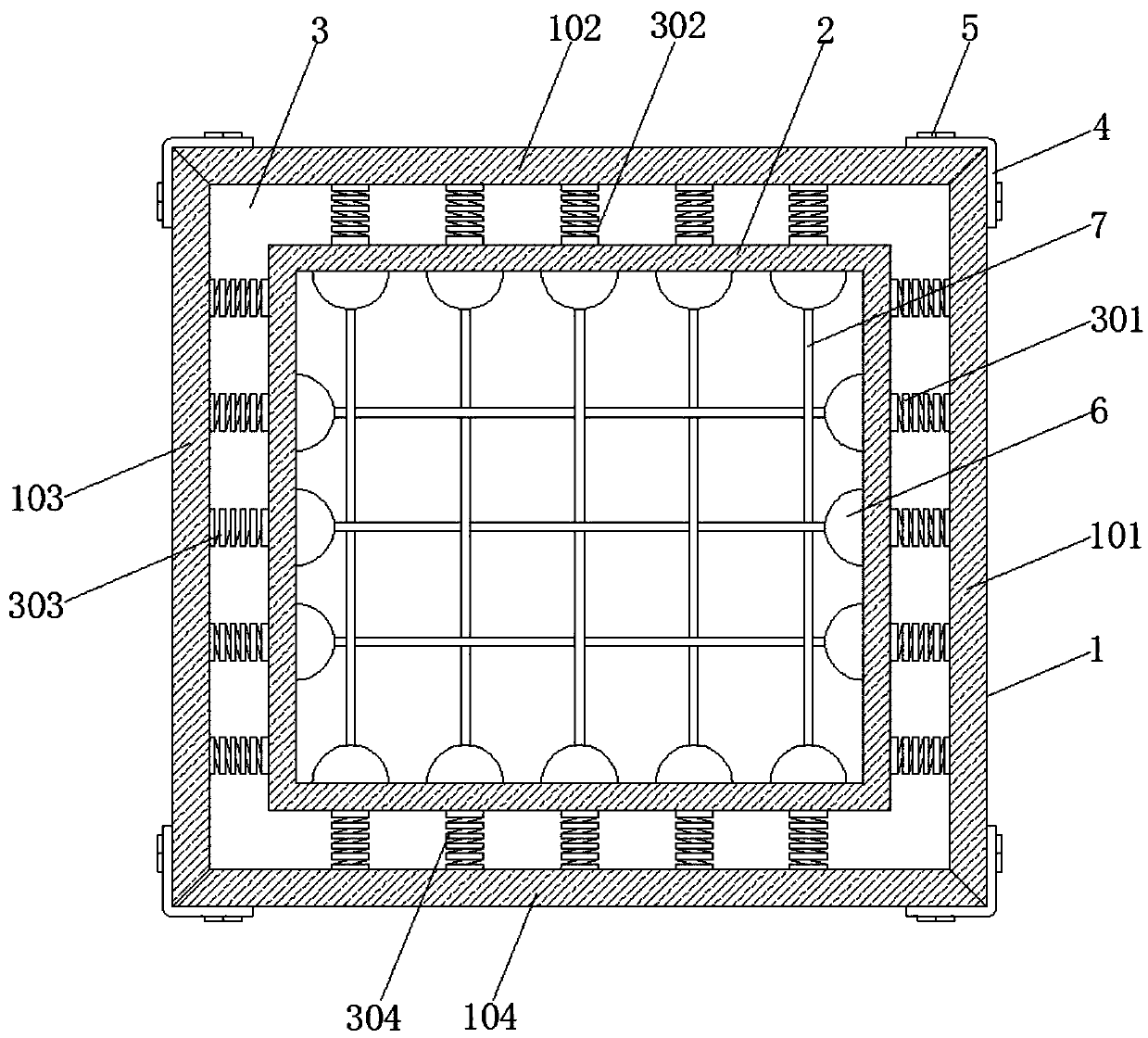

[0022] see Figure 1-2 , the present invention provides a technical solution: a new flow meter packaging box, including an outer plate 1 and an inner plate 2, a gap 3 is left between the outer plate 1 and the inner plate 2, and the gap 3 is respectively A first shock absorbing spring 301, a second shock absorbing spring 302, a third shock absorbing spring 303 and a fourth shock absorbing spring 304 are provided, and the outer layer plate 1 includes a first outer layer panel 101, a second outer layer panel 102, a second outer layer panel 102, Three outer layer panels 103 and the fourth outer layer panel 104, the first outer layer panel 101, the second outer layer pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com