Preparation method of concrete with functions of reinforcing, internal curing and shrinkage compensating

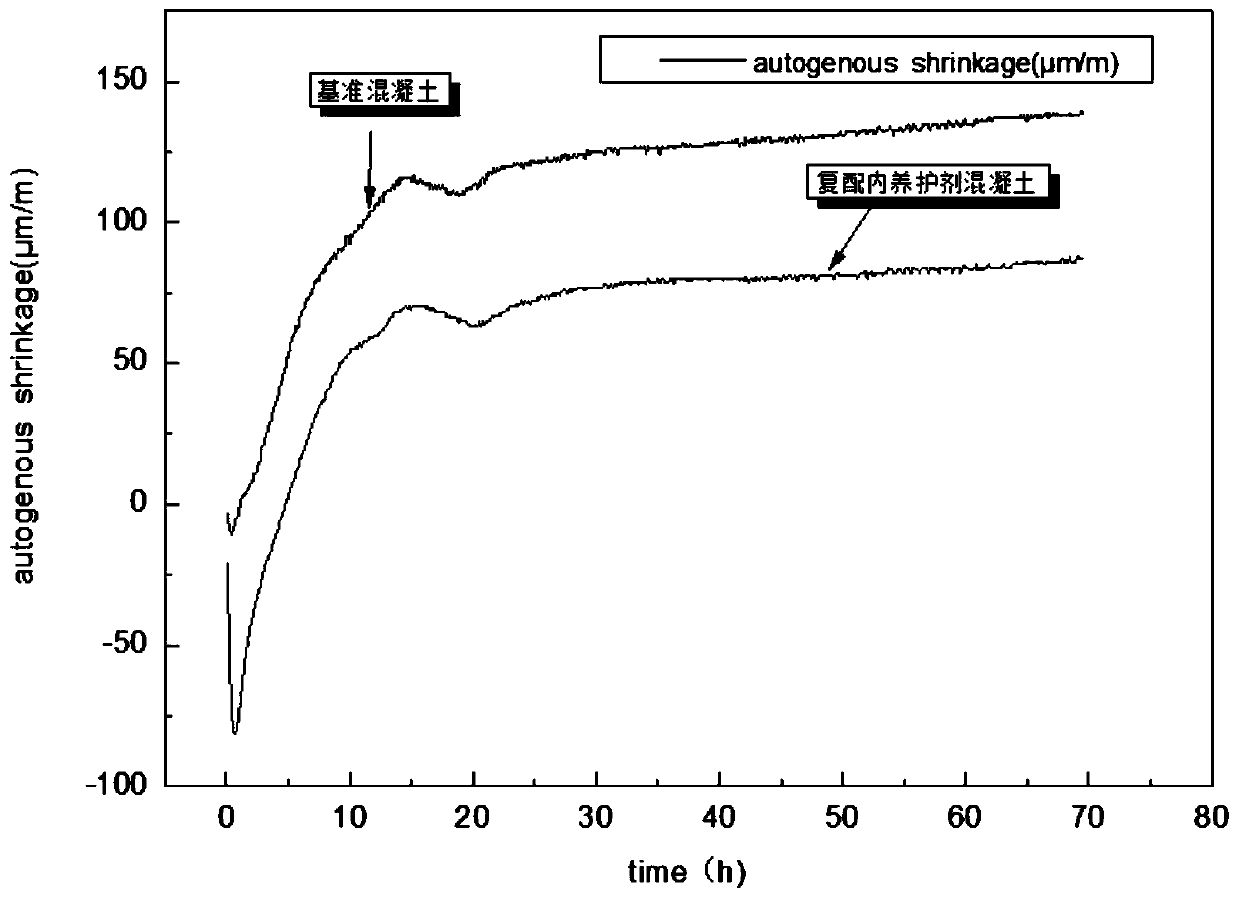

A technology for compensating shrinkage and concrete, which is applied in the field of new building materials, can solve problems such as the reduction of concrete strength, and achieve the effect of inhibiting concrete shrinkage and realizing self-shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022]1) A concrete with the functions of reinforcement, internal maintenance and shrinkage compensation, consisting of 42.5 ordinary Portland cement, silica fume, mineral powder, machine-made sand, stones, water reducing agent, internal curing agent, organic early-strength components, Composed of water and other raw materials, the components weighed per cubic meter are: 380kg of cement, 30kg of silica fume, 70kg of mineral powder, 800kg of machine-made sand, 970kg of stones, 11.9kg of internal culture-water reducing agent, and 155kg of water.

[0023] 2) The internal curing agent is prepared from the original liquid of the internal curing agent and water at a ratio of 1:14. When preparing the internal curing agent, the original liquid and water are stirred together for 5-10 minutes, and the internal curing agent is formed after saturated water absorption for 0.5 hours.

[0024] 3) Compound the internal curing agent and the organic early-strength component at a ratio of 20:1, a...

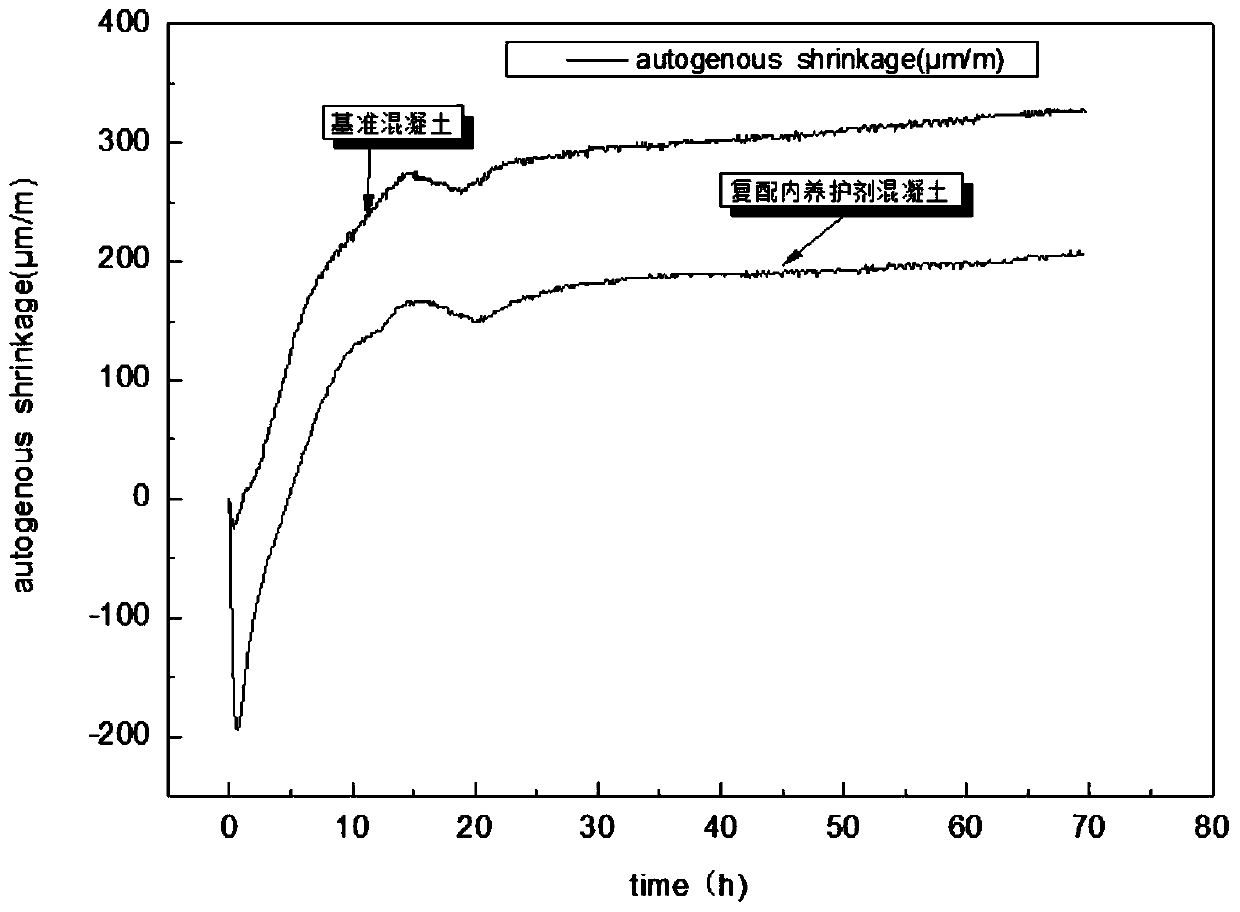

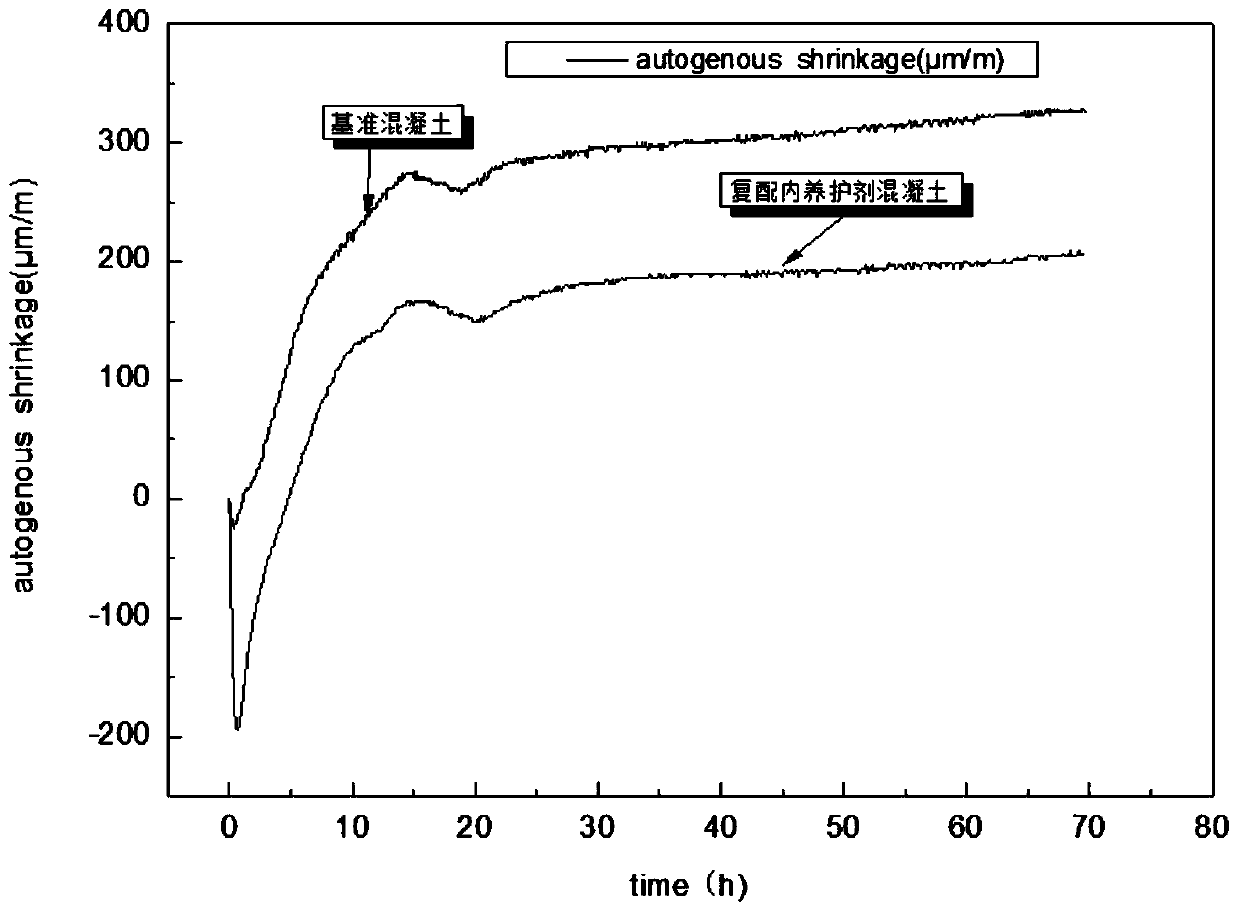

Embodiment 2

[0032] 1) A concrete with the functions of reinforcement, internal maintenance and shrinkage compensation, consisting of 42.5 ordinary Portland cement, silica fume, mineral powder, machine-made sand, stones, water reducing agent, internal curing agent, organic early-strength components, Composed of water and other raw materials, the components weighed per cubic meter are: 440kg of cement, 30kg of silica fume, 70kg of mineral powder, 760kg of machine-made sand, 930kg of stones, 22.4kg of internal culture-water reducing agent, and 155kg of water.

[0033] 2) The internal curing agent is prepared from the original liquid of the internal curing agent and water at a ratio of 1:14. When preparing the internal curing agent, the original liquid and water are stirred together for 5-10 minutes, and the internal curing agent is formed after saturated water absorption for 0.5 hours.

[0034] 3) Compound internal curing agent and organic early-strength component at a ratio of 20:1, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com