Splicing foundation for power station equipment

A splicing and equipment technology, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of long operation period, inconvenient installation of power station equipment foundation, and many construction procedures, so as to protect the environment, facilitate installation, disassembly and transportation, and facilitate on-site installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

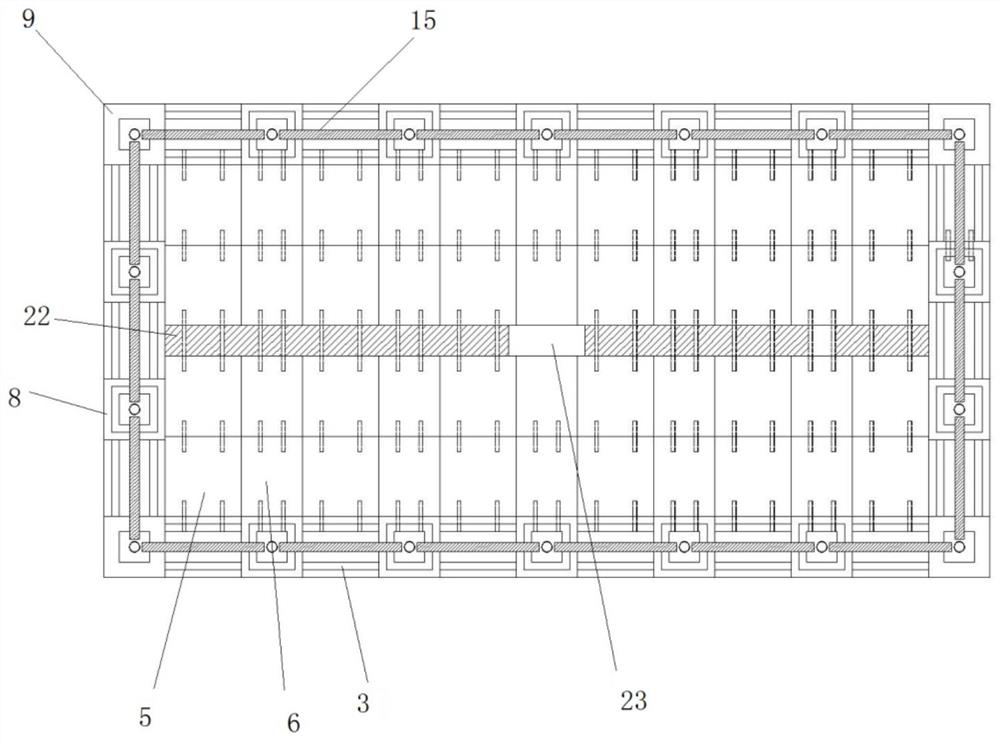

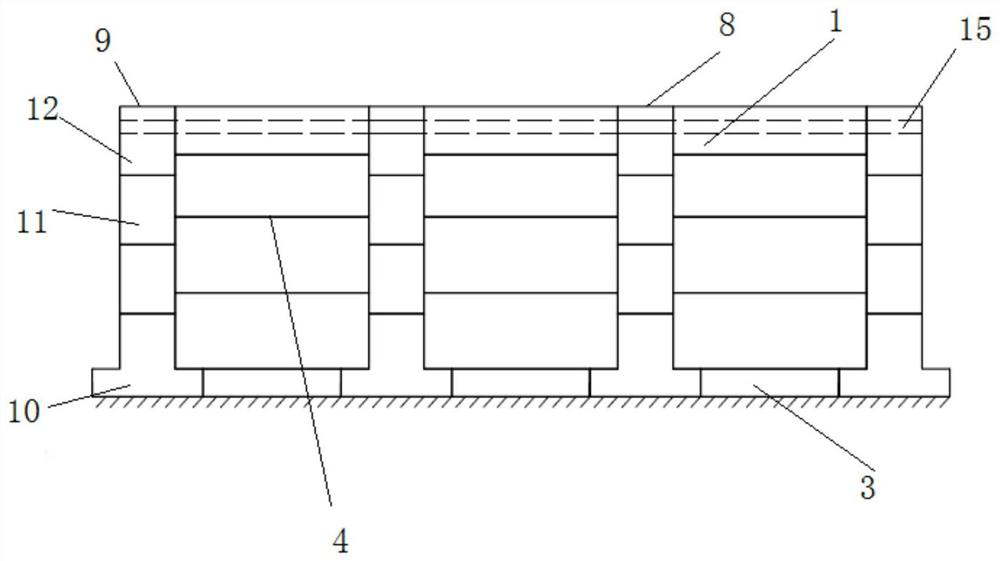

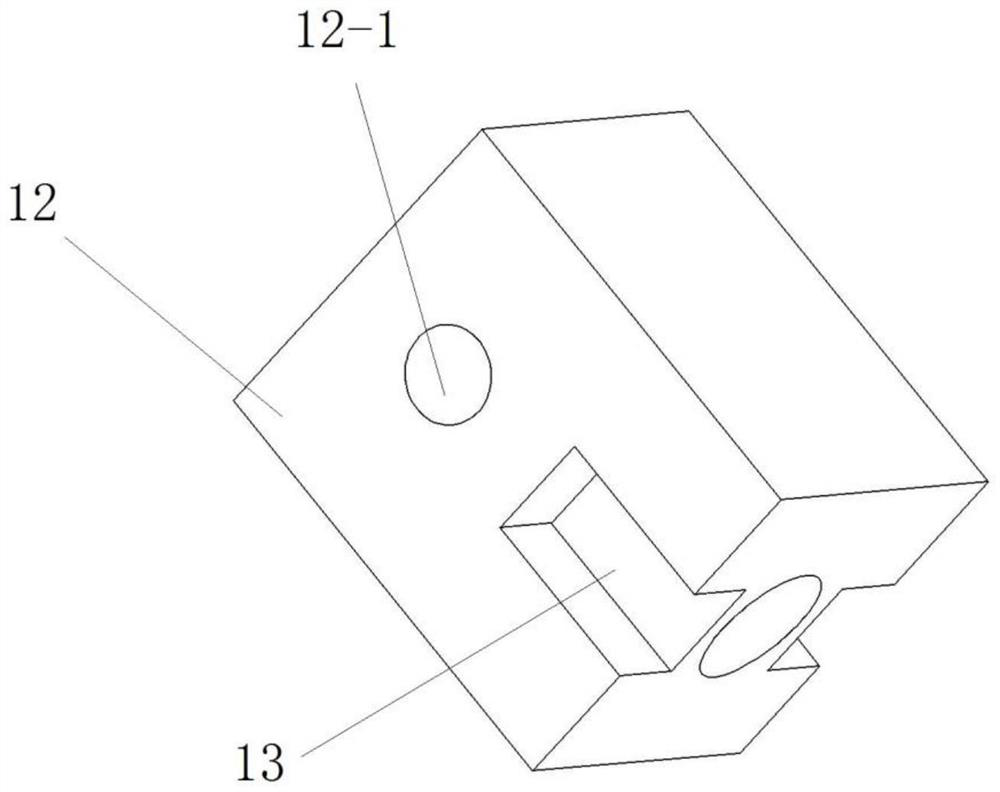

[0034]The mandling foundation of the power station equipment of the present invention, such asFigure 1-2 As shown, including a mutually connected column perpendicular to the ground, the upper lower end of the adjacent two-fitting column is inserted with a pressure beam 1, a prefabricated wall-based 3, and a block 1 and a prefabricated wall group 3. The body 4, the wall 4 is inserted with adjacent two-fitting column; further includes a first connecting member 5, a second connecting member 6, and the first connector 5, a second connector 5, a plurality of layers, respectively. The receiving wall base 3, the second connector 6 is connected to the assembly column; wherein the assembled column includes a neutral post 8, a corner column 9, and the neutral post 8 are fixedly connected to the corner column 9, and the pressure beam 1 is connected by the second co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com