Process equipment and method for sealing and curing the liquid filler of the motor armature after impregnation

A technology of process equipment and fillers, which is used in electromechanical devices, manufacturing of motor generators, electrical components, etc., can solve the problems of small amount of hanging paint, insufficient filling of insulating paint, thin paint layer, etc., to improve insulation reliability and prolong life. Service life, effect of delaying the aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

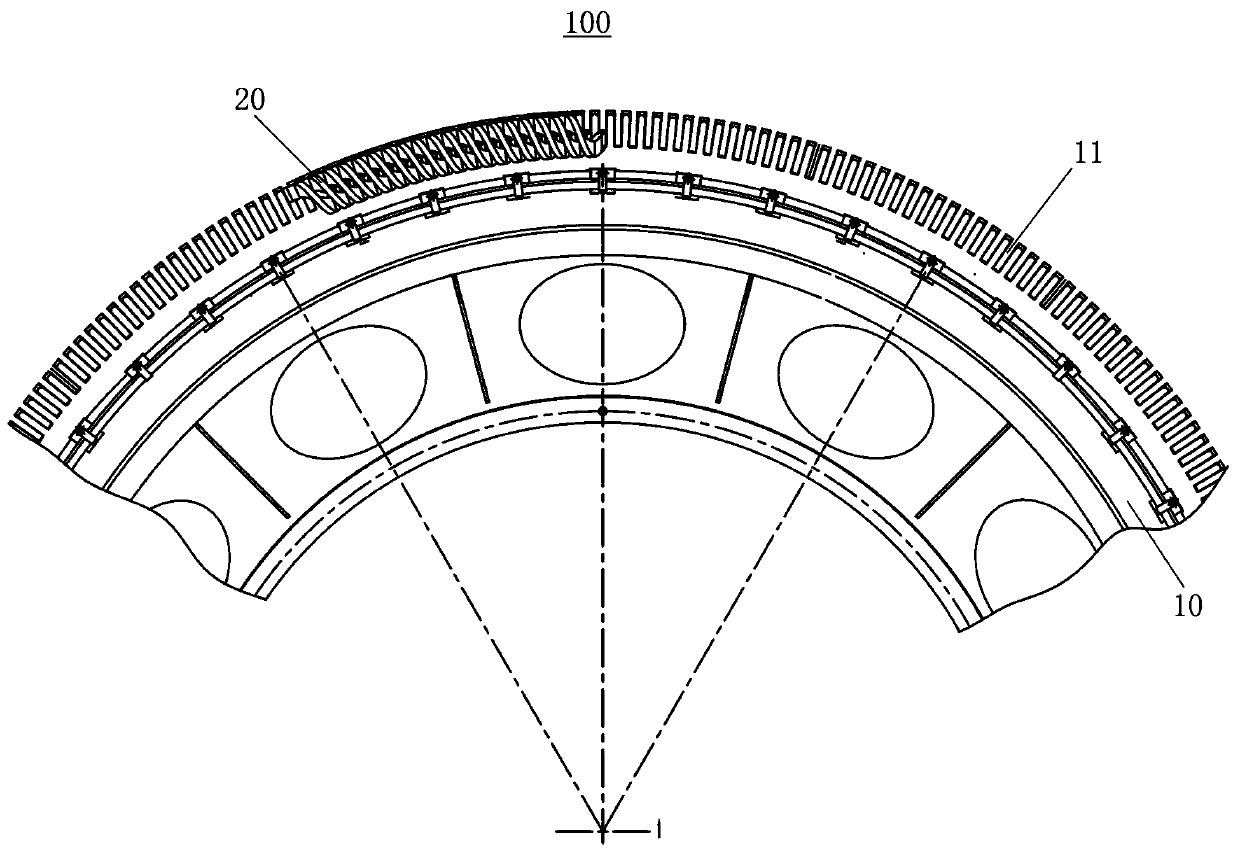

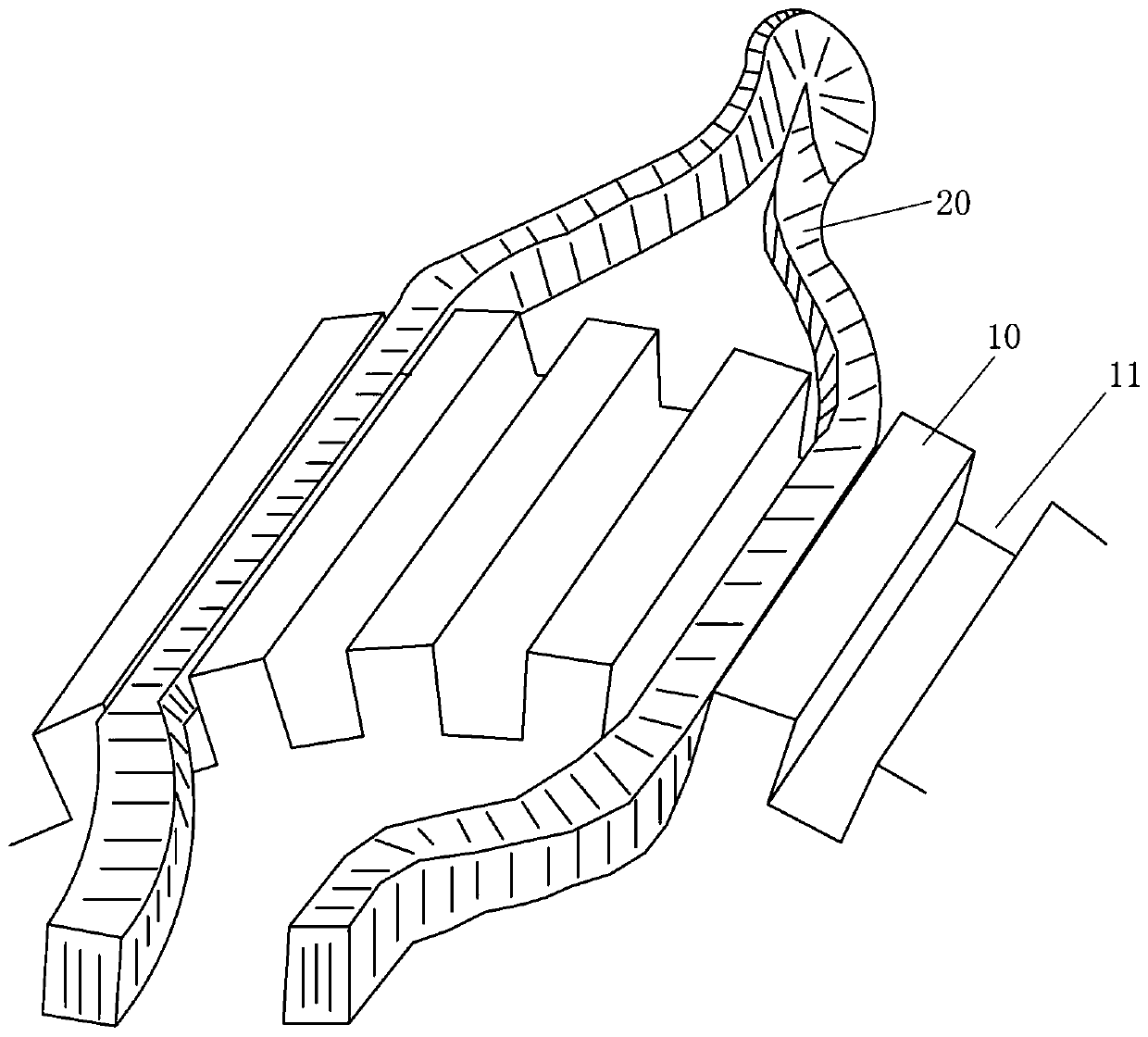

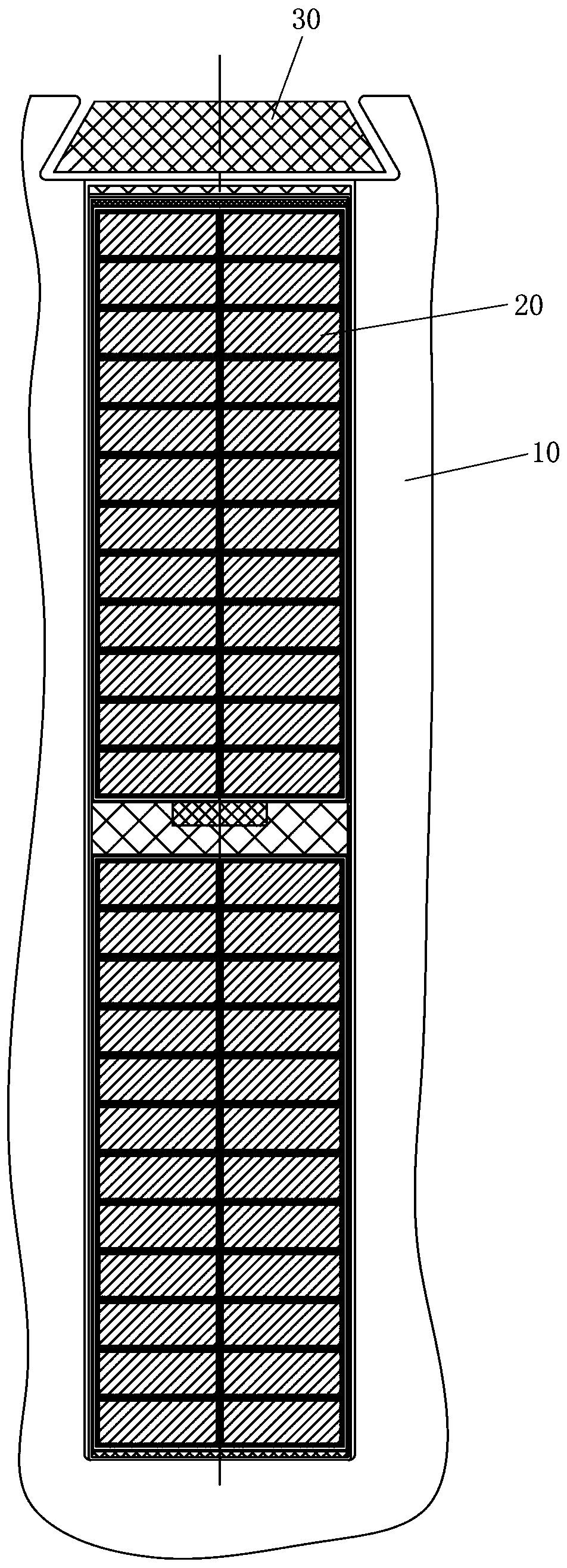

[0055] refer to Figure 4 , Figure 4 A stator motor armature 100 to be cured after dipping is shown according to an embodiment of the invention. The motor armature 100 includes a stator core 10 and a winding 20, the stator core 10 is provided with a winding slot 11, the winding 20 is embedded in the winding slot 11, and a slot wedge 30 is installed at the notch of the winding slot 11 to fix the winding 20 In the winding slot 11.

[0056] The motor armature 100 can be divided into an armature main body 23 and two armature ends 21 and 22, and the liquid filler (for example, insulating varnish or liquid insulating medium etc. on the motor armature 100, for convenience of description, hereinafter, When using insulating varnish (represented by) for curing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com