Special pressing type liquid suction package bottle for cosmetics

A cosmetic and pressing technology, which is applied in household packaging, cosmetic packaging, packaging, etc., can solve the problems of poor connection stability of the dropper and pressing head, unsecured assembly reliability, and unsecured connection strength, etc. Liquid suction and dripping are stable and reliable, good positioning, and prevent falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

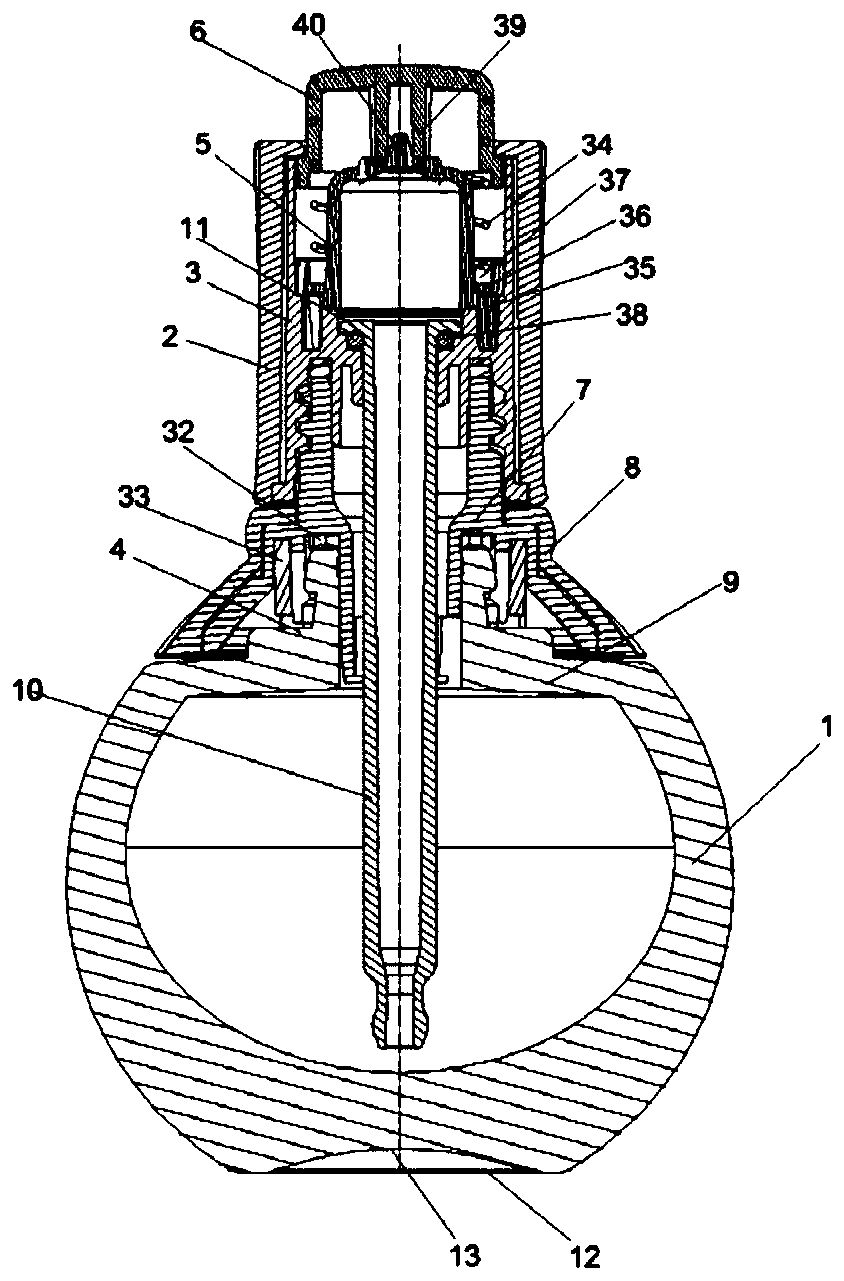

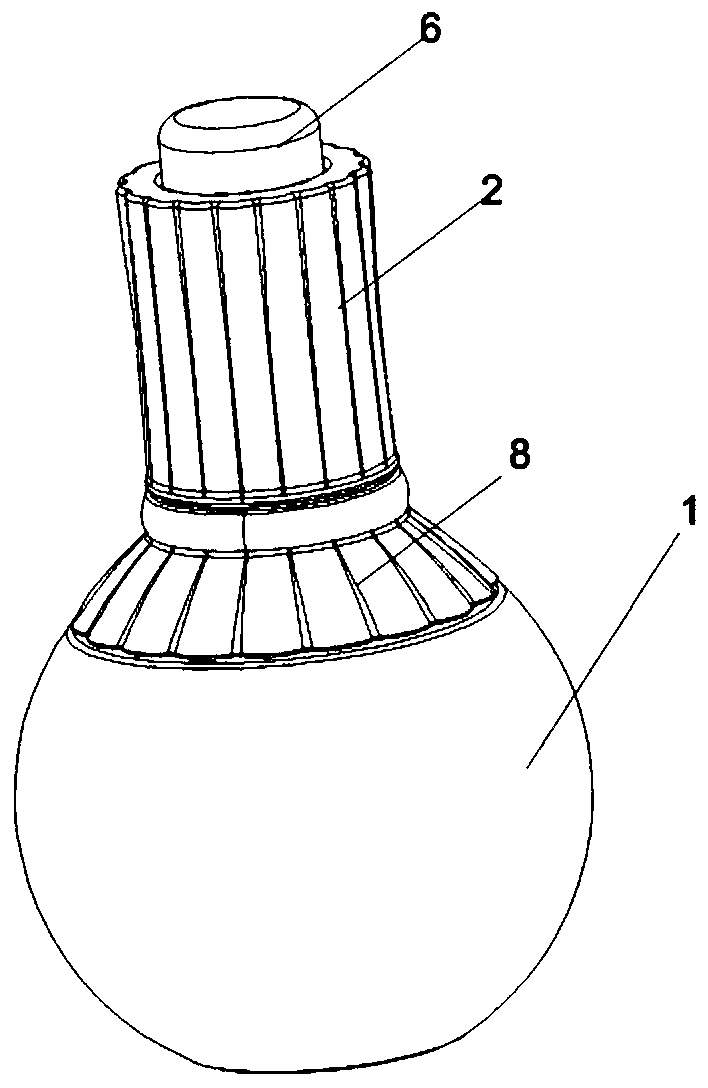

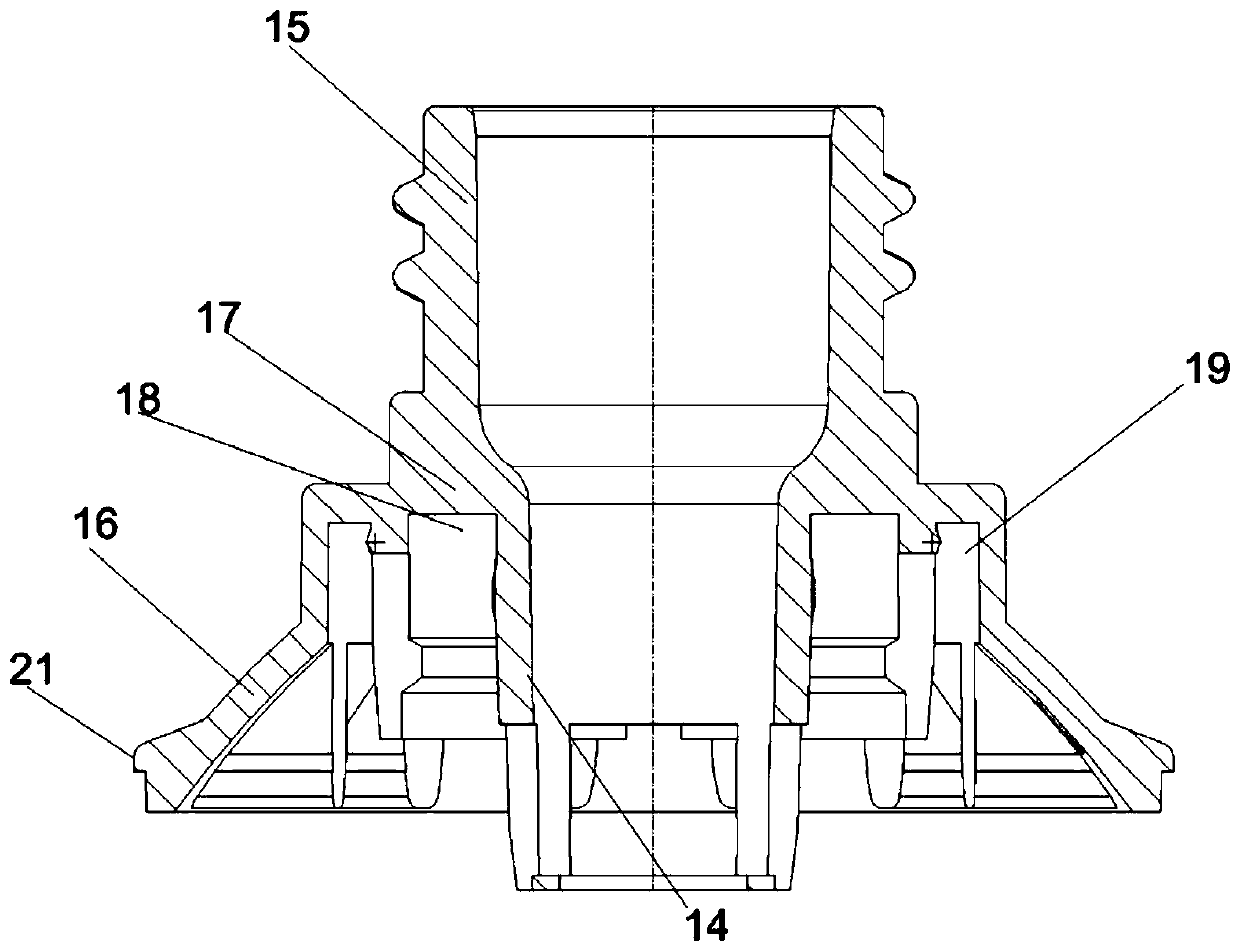

[0037] like Figure 1-10As shown, a special packaging bottle for cosmetics with push-type liquid absorption, including a bottle body 1, a bottle mouth 4 at the top of the bottle body 1, an inner cover 3 installed on the bottle mouth 1, and an outer cover installed outside the inner cover 3 2 and the dropper 10 installed inside the inner cover 3 and the silicone pressing head 5 matching the dropper 10. The inner cover 3 includes an inner cover inner ring 41, an inner cover middle ring 42, an inner cover outer ring 43 and an inner cover connection ring 44 connecting the inner cover inner ring 41, the inner cover middle ring 42 and the inner cover outer ring 43, and a silicone pressing head 5 Installed on the inner cover connecting ring 44, the top of the dropper 10 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com