Unfolding and folding movement device with cable arrangement function and load test device

A motion device and cable technology, which is used in the field of retractable motion devices and load test devices, can solve the problems of large size of motors and other driving devices, unsatisfactory long-term scalability, replaceable loads, and mechanism stuck, etc. Easy and reliable installation, long-term scalability, stable and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

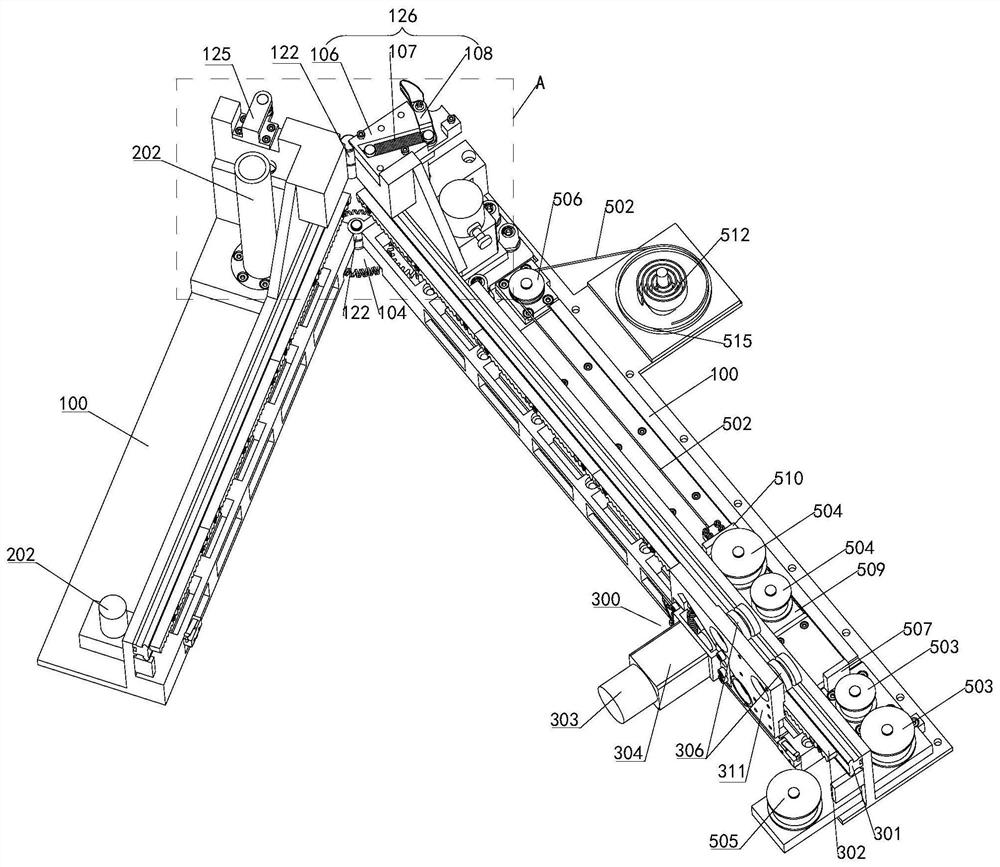

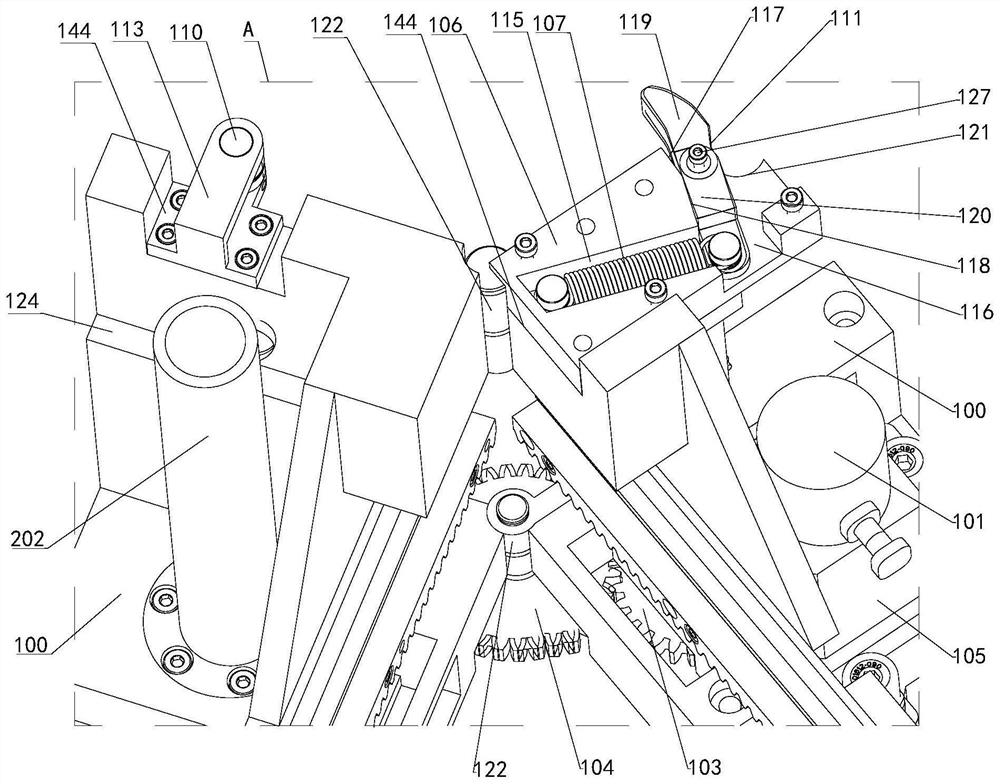

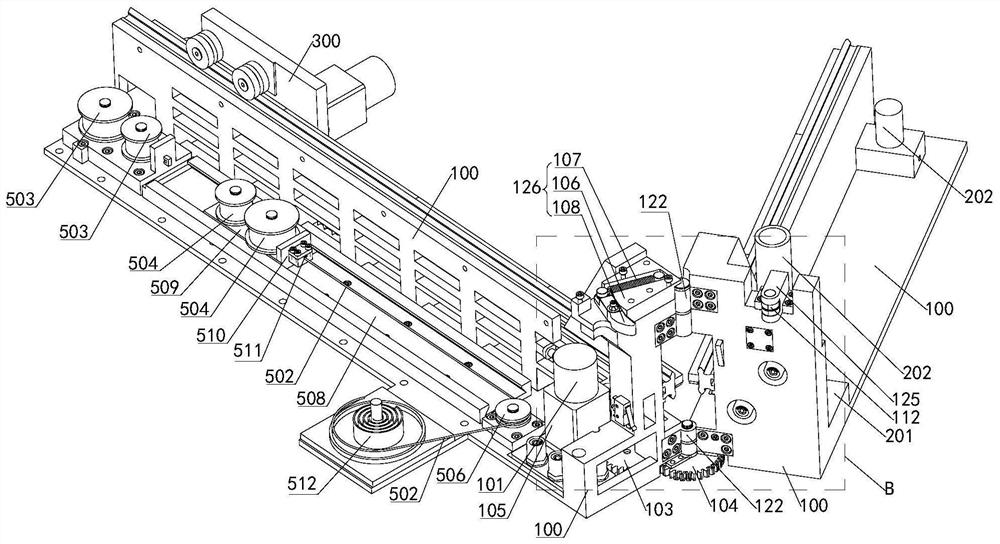

[0079] Such as Figure 1 to Figure 10 As shown, the unfolding and retracting motion device with the function of cable arrangement in this embodiment includes a cable arrangement mechanism 500, an unfolding and retracting drive mechanism, a locking mechanism 126, and at least two unfolding platforms 100 that are sequentially hinged by hinges 122, adjacent to each other. The two deployment platforms 100 are fully deployed under the drive of the expansion and retraction drive mechanism to form a linear support platform; the deployment platform 100 is provided with a movable pulley assembly, a fixed pulley assembly, a retractable assembly and a The X-axis motion assembly 300 that supports the movement of the platform, the fixed pulley assembly and the movable pulley assembly are arranged in sequence along the movement direction of the X-axis motion assembly 300, and the movable pulley assembly is slidably connected to the unfolding platform 100; the first bearing One end of the fo...

Embodiment 2

[0095] In this embodiment, on the basis of Embodiment 1, components such as a retractable drive mechanism and a locking mechanism are described.

[0096] Such as Figure 1 ~ Figure 4 As shown, the power part of the unfolding drive mechanism in this embodiment is installed on one of the two adjacent unfolding platforms 100, and the transmission gear 104 of the unfolding drive mechanism is rotatably connected to two adjacent unfolding platforms 100. on the hinge 122 of the unfolding platform 100, and is connected with another unfolding platform 100; the locking mechanism includes a latch 125 and a locking assembly 126, and the latch 125 and the locking assembly 126 are respectively installed on two adjacent on the first unfolding platform 100; the power part of the unfolding and retracting driving mechanism is connected with the transmission gear 104 and drives the transmission gear 104 to rotate around the hinge 122, and then drives the other unfolding platform 100 to rotate ar...

Embodiment 3

[0113] Such as Figure 9 ~ Figure 17 As mentioned above, this embodiment provides a preferred solution of the X-axis motion assembly 300 . The X-axis motion assembly 300 includes a first slider 311 and a first driving device, a first guide rail 301 and a first rack 302 are horizontally installed on the deployment platform 100, and the driving end of the first driving device is connected with The first driving gear 305 adapted to mesh with the first rack 302, the first driving device is installed on the first slider 311; the first slider 311 is provided with a first roller 306 and a second The roller 307, the first roller 306 and the second roller 307 are slidingly connected to the upper and lower sides of the first guide rail 301 respectively, and the first slider 311 is also provided with a lever loading device, and the lever loading device and The first roller 306 or the second roller 307 is connected to provide a pre-tightening force for the first roller 306 or the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com