Porous sheet assembled three-dimensional NiO porous sphere and synthetic method thereof

A synthesis method and porous sheet technology, applied in the field of nanomaterials, can solve the problems of reduced surface active sites and catalytic activity, easy aggregation, and large specific surface energy of two-dimensional nanosheets, achieving low cost, improved diffusion efficiency, and difficult Aggregated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for synthesizing three-dimensional NiO porous spheres with porous sheet assembly: comprising the following steps

[0022] a. Dissolve 0.0290g of nickel nitrate hexahydrate and 0.0123g of isonicotinic acid in a mixed solution of N,N-dimethylformamide (9mL), absolute ethanol (5mL), deionized water (1mL), and stir Evenly, transfer the above mixed solution to an autoclave, and react in a 25mL polytetrafluoroethylene autoclave, heat to 150°C, and the reaction time is 6h;

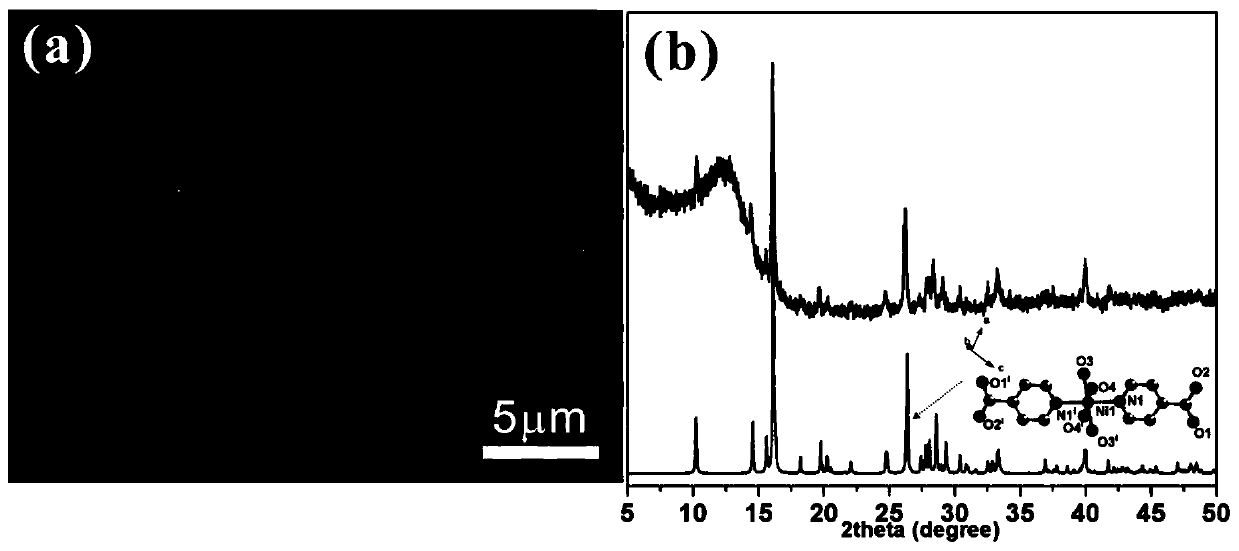

[0023] b. Collect the product by centrifugation, then wash the product several times with absolute ethanol, and dry it in an oven overnight to obtain the isonicotinic acid coordination compound precursor of nickel. The SEM image is as follows figure 1 As shown in a, it can be seen from the scanning electron microscope that the obtained product is a porous ball structure assembled by smooth sheets, and the size of the porous spherical precursor is relatively uniform. XRD picture as shown figure 1...

Embodiment 2

[0026] A method for synthesizing three-dimensional NiO porous spheres with porous sheet assembly: comprising the following steps

[0027] a. Dissolve 0.0290g of nickel nitrate hexahydrate and 0.0123g of isonicotinic acid in a mixed solution of N,N-dimethylformamide (9mL), absolute ethanol (5mL), deionized water (1mL), and stir Evenly, transfer the above mixed solution to an autoclave, and react in a 25mL polytetrafluoroethylene autoclave, heat to 130°C, and the reaction time is 6h;

[0028] b. Collect the product by centrifugation, then wash the product several times with absolute ethanol, and dry it in an oven overnight to obtain the nickel isonicotinic acid coordination compound precursor;

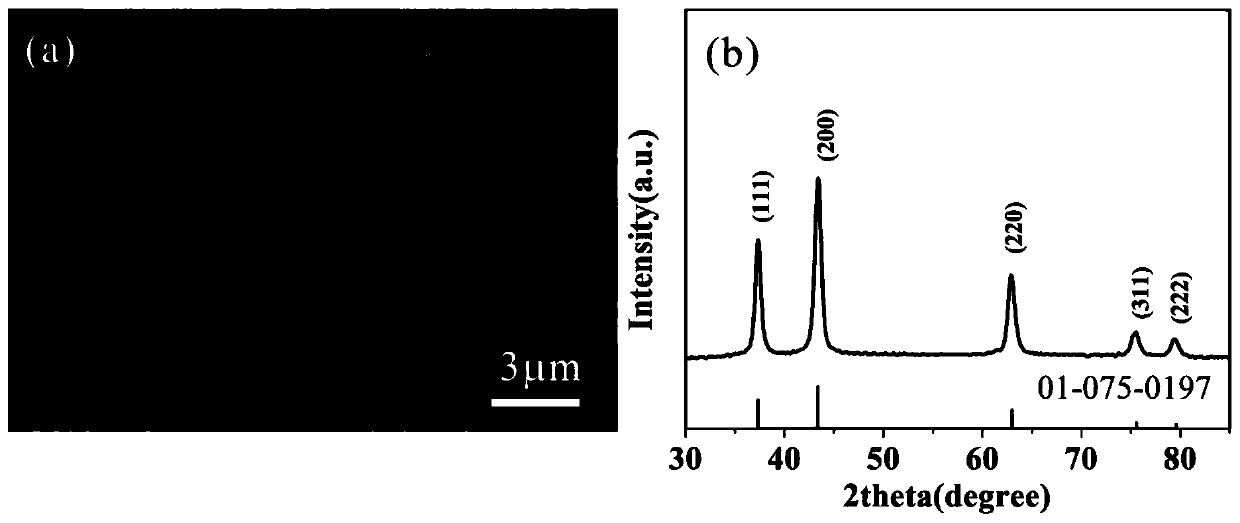

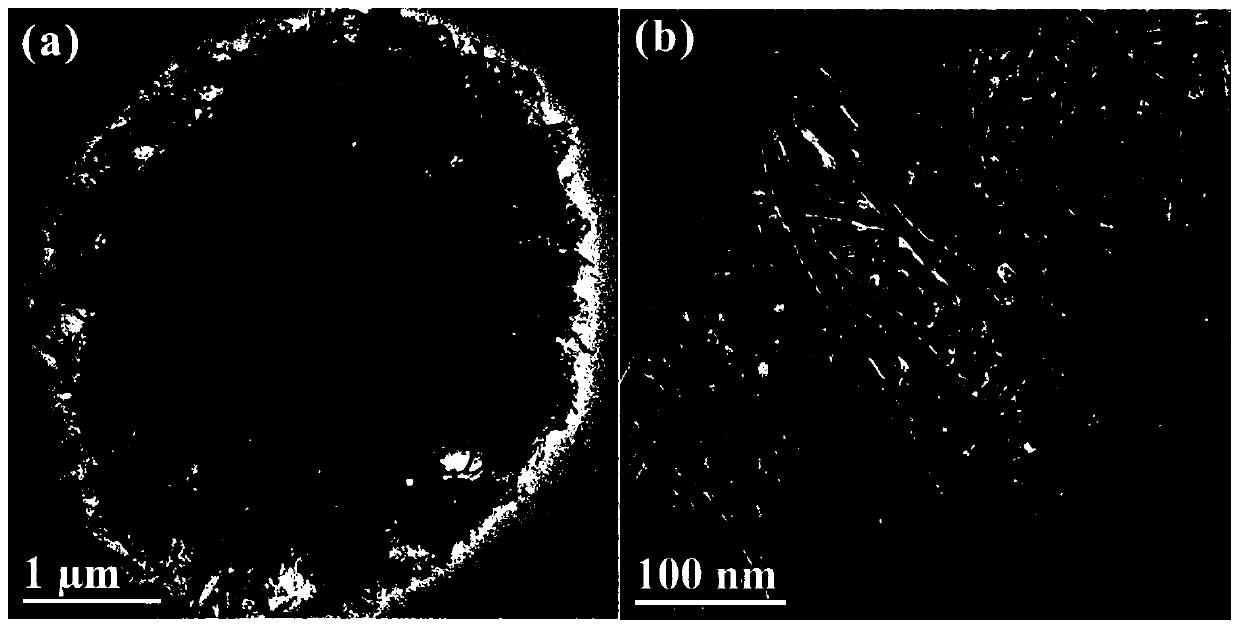

[0029] c. Carry out high-temperature calcination on the obtained precursor in a vacuum atmosphere, the calcination temperature is 450°C, and the time is 2h. The SEM image of the obtained product is as follows Figure 4 As shown in a, from Figure 4 a It can be seen that the obtained pr...

Embodiment 3

[0031] A method for synthesizing a three-dimensional NiO porous sphere with porous sheet assembly: comprising the following steps

[0032] a. Dissolve 0.0290g of nickel nitrate hexahydrate and 0.0123g of isonicotinic acid in a mixed solution of N,N-dimethylformamide (9mL), absolute ethanol (5mL), deionized water (1mL), and stir Evenly, transfer the above mixed solution to an autoclave, and react in a 25mL polytetrafluoroethylene autoclave, heat to 160°C, and the reaction time is 4h;

[0033] b. Collect the product by centrifugation, then wash the product several times with absolute ethanol, and dry it in an oven overnight to obtain the nickel isonicotinic acid coordination compound precursor;

[0034] c. Carry out high-temperature calcination on the obtained precursor in a vacuum atmosphere, the calcination temperature is 550°C, and the time is 1h. The SEM image of the obtained product is as follows Figure 4 As shown in b, from Figure 4 b It can be seen that the obtained p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap