Freight train dowty retarder based on ball screw mechanism

A ball screw, freight train technology, applied in transportation and packaging, railway car body parts, rail brakes, etc., can solve the problems of polluting the environment, deceleration performance of the deceleration top, and achieve high bearing capacity, reduced vibration, and stable position. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

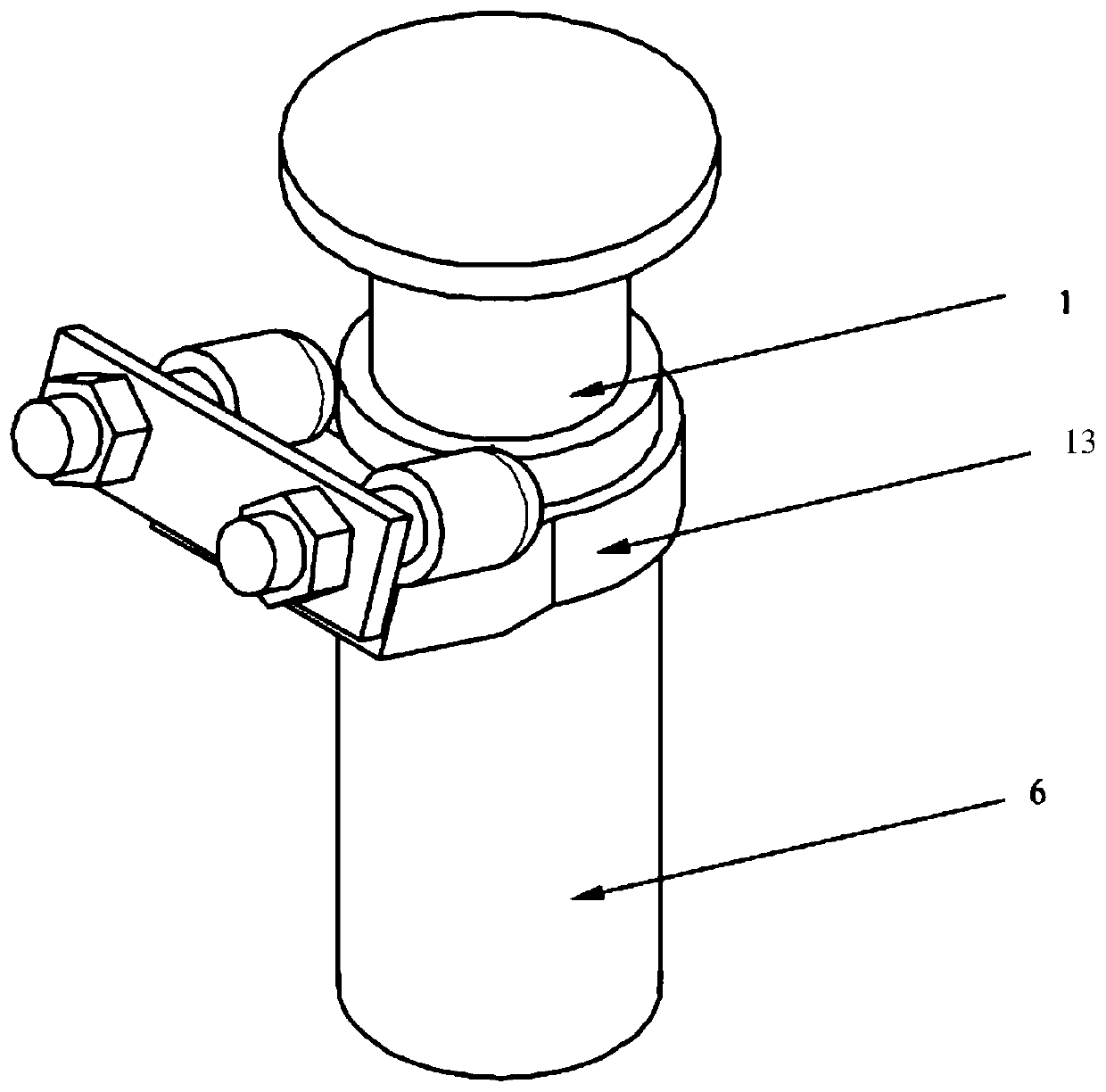

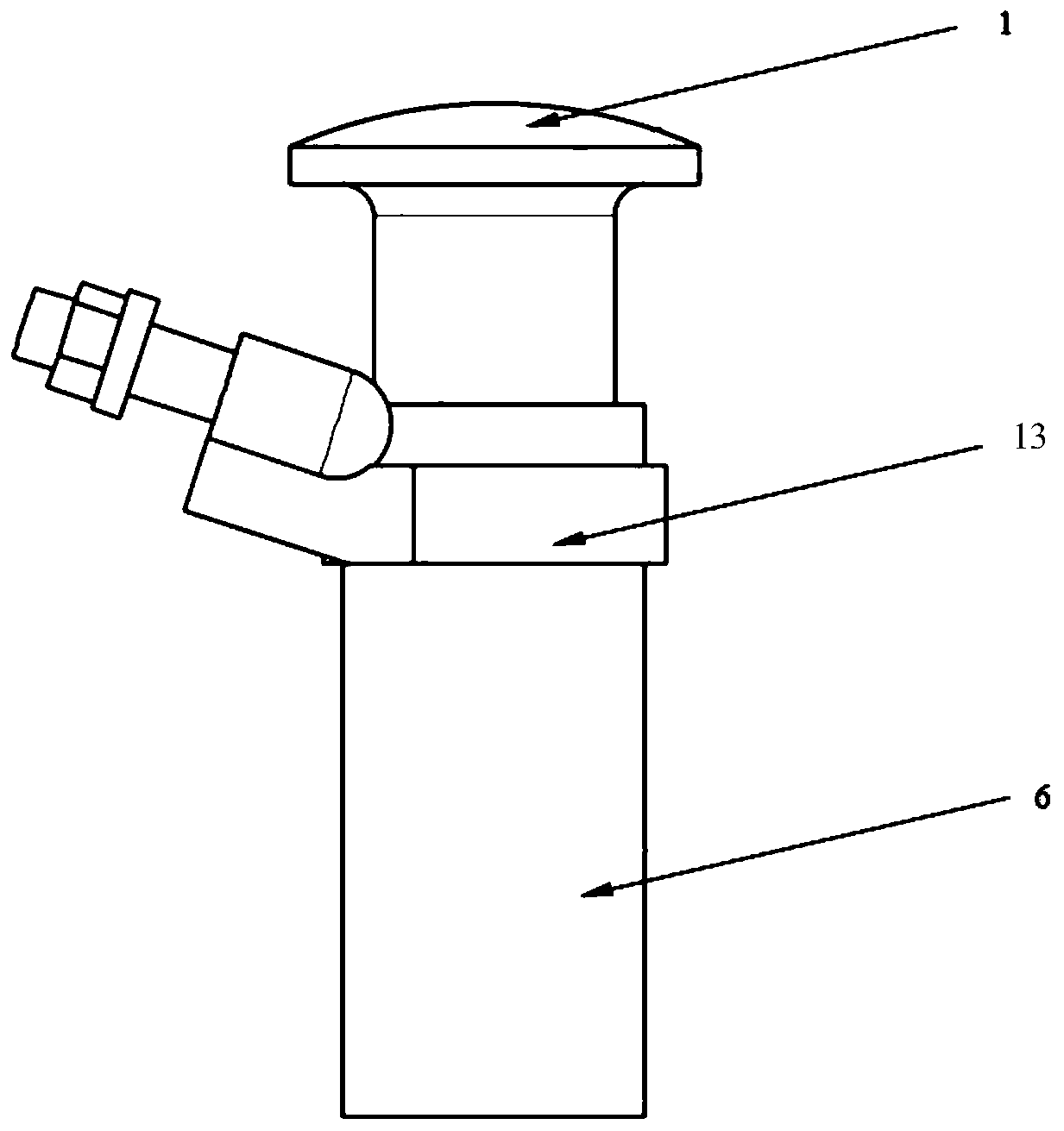

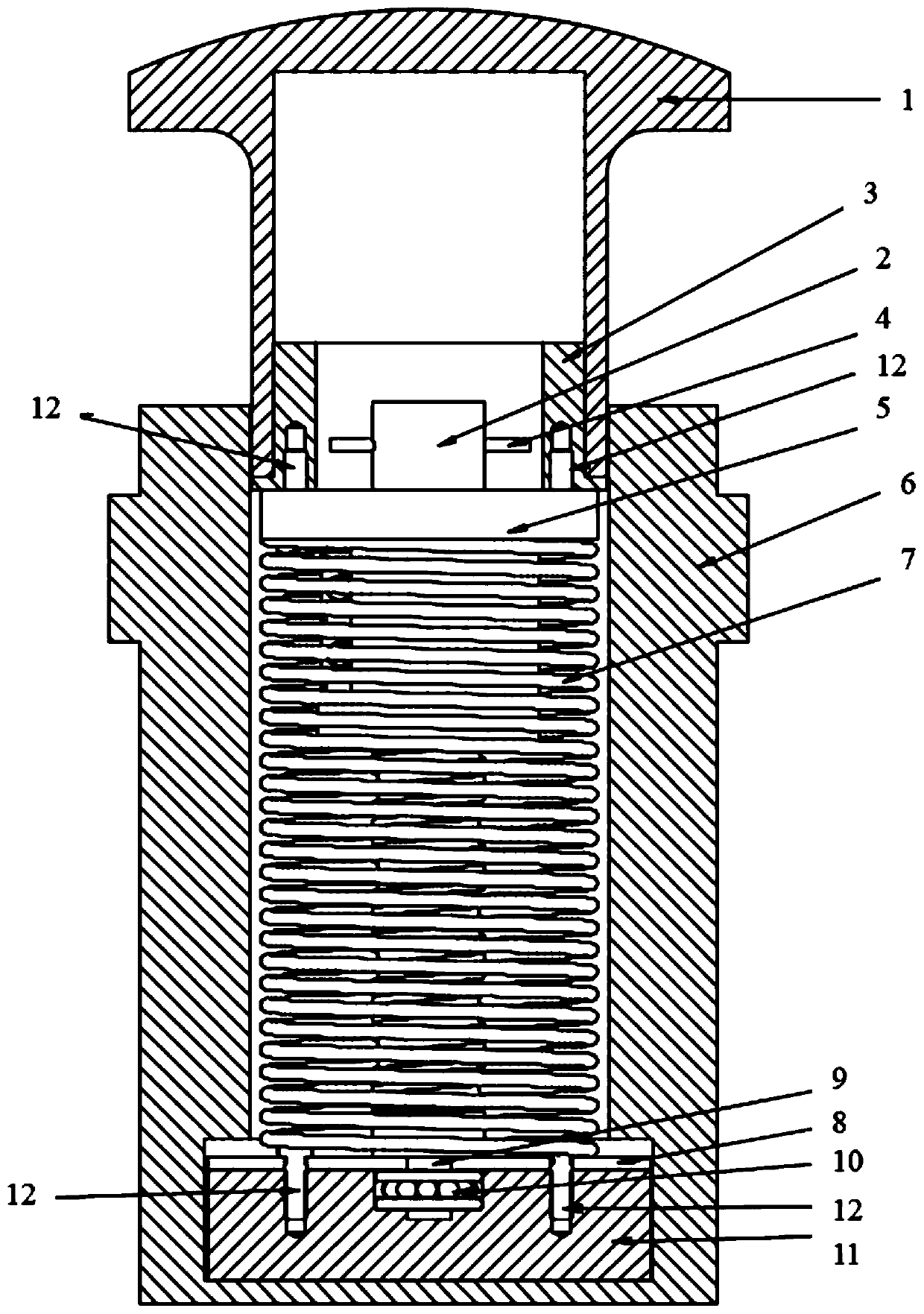

[0038] Combine below Figure 1 ~ Figure 3 The present invention will be described in detail.

[0039] A freight train deceleration roof based on a ball screw mechanism, comprising a roof 1 and a base 6, a hollow chamber is opened in the base 6, and the top of the hollow chamber is open. The top 1 is arranged in the opening and can slide up and down in the opening. It also includes a ball screw 2, the ball screw 2 is equipped with a nut 5, the top 1 is fixedly connected with the nut 5, the inner side of the hollow chamber opened in the base 6 is connected with a fixing device, the lower part of the ball screw 2 is connected with the fixed The device is rotatably connected, and the ball screw 2 is covered with a spring 7, and the spring 7 is located between the nut 5 and the fixing device. Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com